Rubber Sealants: Description and Specifications

The closure of holes, crevices, the elimination of various cavities is very often necessary during repair and construction. Even exclusively for domestic purposes, such processing is practiced by many people. This means that you need to thoroughly examine what rubber sealant is and how to use it correctly.

Special features

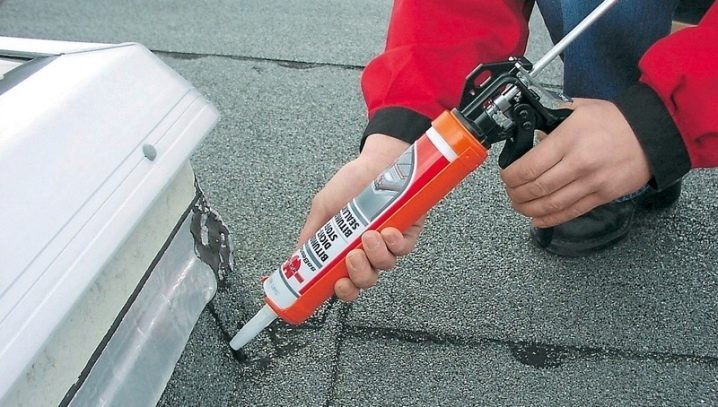

In practice, sealing compounds are not always used in pure form. Often used mixed reagents, such as "Titanium", formed by combining rubber with resin, bitumen, synthesized fibers and even solvent. Such structure perfectly proved when performing roofing works. Judging by the estimates of professional and amateur builders, this sealant is characterized by high viscosity and perfectly tolerates harmfulatmospheric effects.

Basically, this mixture is needed for the following purposes:

- closing of the junction of blocks;

- elimination of gaps;

- update previously formed joints;

- struggle with flowing places;

- increase of rigidity of drains and dormer-windows.

The classic sealant based on rubber along with bitumen analogues is used in the following:

- in the repair of rooms and utility rooms with excessive moisture;

- when holes appear in inflatable boats and rubber boots;

- when restoring the integrity of roofing materials;

- for fastening of roofing material and other coatings of bitumen;

- for attaching polystyrene or polyurethane to any base.

Using

Rubber sealants are required to be applied only at positive temperatures. No other type of sealing compositions allows refusing the cleaning of the finished surface. A rubber due to its exceptional adhesion makes it possible to get rid of this tedious procedure. When the compound is applied, it quickly hardens, becomes insensitive to changes in the weather.

If necessary, the sealed surface can be repainted in a short time to match the tone of the surrounding material.

Positive and negative sides

Reviews of rubber sealants suggest that they have such properties as:

- extremely elastic;

- adhere perfectly to almost any building material;

- prevent corrosion;

- can be operated at a frost of -50 degrees;

- stable even when heated to +150 degrees;

- serve up to 20 years;

- easily tolerate wind, rain, hail, snow, dew.

But we have to put up with certain limitations. So, rubber sealants are incompatible with a number of plastics, because there is a risk of material destruction. The sealing layer, in turn, may be disturbed by mineral oils.

The most attractive variety

Liquid rubber Masterteks is famous for its excellent adhesion on wet and oily-coated substrates. It is compatible with bitumen, fits well on brick. Positive results were noted with the use of liquid rubber when joining a railing with a wall or plaster. This material allows you to glue the copper window sills on oak slopes, to seal the ligaments between wood and copper, stone surfaces and sheet glass. Such characteristics allow the use of sealant when closing the borders of decorative panels, in the installation of plumbing and air conditioning, PVC and aluminum double-glazed windows.

Liquid rubber can confidently replace the compositions based on polyurethane, silicone, polymers and other actively used sealing means. The resulting layer is mechanically strong, but elastic. Hardening occurs due to a reaction initiated by moisture in the air. Therefore, the sealant must be carefully protected from moisture and opened only for use. If you follow the proprietary processing technology, even contact with saline ocean water or exposure to ultraviolet radiation will not pose any threat.

Masterteks cannot cope with zinc-coated metal. If you seal them vertically oriented joints, they will not slide.

Curing time is determined by the following factors:

- relative humidity;

- its warming up;

- size of the created layer.

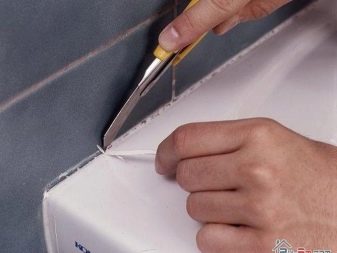

While the mass is not frozen, it is easy to clean with solvents or household chemicals. Solid surpluses are removed mechanically, additional cleaning is performed with silicone removal mixtures.

If you have to do extremely deep seams, you need to use a cord of round polyethylene foam.The sealant in such seams is laid out either with a spatula or with a mounting gun. The second tool is more expensive, but much more productive and more accurate.

Masterteks can also be used when the frost is -10 degrees, and during the summer heat up to +40 degrees. According to the manufacturer, the sealant is resistant to mold and other fungi. The seam formed by it does not pass water, and at the same time it is outwardly invisible. You can store the mixture at temperatures from +5 to +25 degrees. Resistance after hardening of the applied layer is guaranteed in the range from -40 to +90 degrees.

To learn how to seal the roof with the FOME FLEX AQUASTOP roofing rubber sealant, see the following video.