Acrylic anticorrosive primers-enamels: features of the choice and use

Having come to the store to get the coloring composition, the consumer is lost in a large assortment. Even a professional is not easy to find the right enamel.

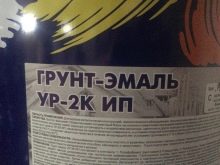

The original and versatile in the application of the composition is acrylic primer-enamel.

Main cast

It is obvious that the main component of this composition is acrylic. In addition to it, the composition of such enamels includes a color pigment, a solvent (water), as well as such additives for greater storage of the emulsion, as antiseptics, various water-repellent and fire-fighting odorants.

The composition may vary depending on which material it will be used for. For example, in an emulsion intended for wood, antifungal additives are added, and in metal lacquers - water-repellent.The last composition is anti-corrosion primer enamel.

Advantages and disadvantages

The most important advantage and, in fact, the reason for creating such a composition is its plasticity after drying, which allows such a coating to withstand temperature changes. Simply put, after severe frosts, the composition does not crack, but in strong heat it can stretch slightly, without disturbing its structure.

As a rule, such a composition, because of its high technical characteristics, processes the metal parts of agricultural machines and other objects of infrastructure.

The advantages of acrylic coating:

- retains its color well, while using acrylic emulsion it is possible to cover materials that are constantly exposed to the sun (for example, a window sill treated with this composition will not lose its color for a very long time);

- adheres well to the material and, after drying, becomes elastic (it can be added that the surface does not crack with time, as is sometimes the case with other coloring compositions, and an anti-corrosion emulsion is produced for the metal, which protects its surface from various effects)

- a sufficiently long lifespan for a coloring agent — almost 20 years for metal, but for wood — 8 years;

- does not react with oils or aggressive chemicals.

Of the obvious flaws, it is possible to note the high price and one of the most common problems on the modern market — the likelihood of acquiring a fake.

Before starting work it is important to completely clean the surface from stains.

It is not enough just to wipe it with a dry cloth, it is necessary to process everything with a special degreasing compound. Without this stage, the subsequent result from the application of enamel can come to naught.

How to apply

The preparatory stage is very important. Before applying, as we have already written, it is necessary to clean the surface from all stains, other coatings and degrease it with the help of special compounds. Acetone is most commonly used., but in stores you can find other degreasing compositions.

The enamel should be applied in a room where the temperature will be not lower than +5 and not higher than +35 degrees. It should not be too humid (no more than 80% humidity).

There are cases when the whole process is carried out in the open air, but it is best to do it indoors to avoid sticking of debris to the surface.

The emulsion can be applied in several ways: with brushes, roller, spray or vacuum coating. But what method of application you would not choose, the consumption of an emulsion weighing 25 kg will be 250 square meters.

The two-layer coating with enamel-primer will provide surface protection for a period of almost 20 years.

Reviews

Acrylic priming enamels of the “universal” group, which provide electrochemical protection of metals, are popular with consumers. They include zinc and silver, which slow down the corrosion process almost twice at a constant touch of metal with salt and fresh water.

Another popular product in the domestic market - quick-drying paint on metal "Tex Universal". It is acquired in order to process the iron bars, fences, paint the garage. Consumers say that the surface is resistant to various kinds of oils and is not covered with rust.

It happens that consumers simply prefer polyurethane varnish, which has all the same properties and characteristics, to all paint coatings. Unlike the primer enamel, it is used for interior work such as coating the floor surface.

Application of primer-enamel will provide a pleasant aesthetic appearance and protect the surface for many years. And this is with all the simplicity of the application and the low price of material consumption.

From the video below you will find out which is the best enamel - acrylic or alkyd?