Polyurethane paint: the pros and cons

Paints for construction and repair work are one of the main materials, because they provide a uniform coating of almost all surfaces. They are easy to use, so anyone will be able to freshen up the interior in their home or apartment, creating a design according to their taste and color preferences.

Special features

Polyurethane paintwork materials are a large group of polymers. The main component is polyols. The second component of polyurethane products are hardeners. As a result of the binding of the molecules of the components of the paint, a film is formed that is resistant to moisture, acids, various organic oils and gasoline.Therefore, polyurethane paint has a number of protective properties, due to which it has resisted a negative atmospheric effect on the surface for quite a long time. Such a suspension is used for finishing inside and outside the premises, as well as for painting various designs.

The paint has a large temperature range of use - from +150 to -40 degrees. The main features of the composition are high technical characteristics, among which may be noted:

- adhesion equal to 2 points;

- conditional viscosity, comprising 50-90 units;

- the presence of volatile substances in the suspension at a level of not more than 34%;

- elasticity of the composition on the fold does not exceed 1 mm;

- dry film coverage is 75 grams / 1m2.

To obtain the desired color and shade used pigment.

Advantages and disadvantages

Due to its unique characteristics, polyurethane paint is higher than other types of paint and varnish materials. There are a number of positive qualities that made possible the wide use of such dyes.

- Excellent durability and wear resistance due to which paint is used in industry.

- Compatible with any surfaces.The compositions are purchased for processing and protection of concrete foundations, metal, wood surfaces, stone, as well as various porous materials.

- Lack of discharge, including hazardous substances. Such a positive feature of the composition is due to the fact that polyurethane itself is harmless.

- Resistance to the influence of aggressive environment gives the ink products the opportunity to perform their main tasks much longer than other similar products.

The disadvantages of polyurethane coloring compositions include their high cost in comparison with other paints and varnishes, as well as a small selection of options on the market in this category. There are not many such products on the counters of supermarkets; therefore, it can be very difficult to purchase an optimal product according to its characteristics.

Kinds

The composition of polyurethane coatings can be divided into two groups:

- two-component productsrequiring mixing, since each component is produced in a separate container;

- single component paintsthat do not require mixing - they can be applied immediately after the acquisition and preparation of the surface, since all the main components are already present in the product.

In one of the cans of a two-component composition is a hardener, in the second - resin. This variety is much stronger and is more resistant to external negative factors affecting the surface. The means is captured without the participation of water vapor from the air, which greatly expands the range of use of the means.

To process the substrate with a two-component material, you can mix only the required amount of paint, and use the rest of it later.

Classification of one-component paints on the basis of the type

To classify one-component paints, they can be divided into three categories:

- products based on organic compounds;

- alkyd-urethane agents;

- water dispersion suspensions.

The composition of the polyurethane compositions of the first category, in addition to the main elements, includes xylene or toluene. For dilution of such materials specialized solvents are produced. A solid state means reaches due to the reaction of components with moisture from the air. Therefore, the time required for the complete drying of this type of paint will depend on the level of humidity in the room.

The second type is composed of alkyd-urethane varnish. A distinctive feature of this paint is a very short drying time, usually it takes an hour and a half. In the role of solvent for alkyd-urethane products, white spirit is additionally purchased.

The latter type has a similar name due to the solvent that is used for this product - in the process of working you will need ordinary water. Water-dispersion paints are odorless and harmless to humans, when painting the surface with such a composition there is no need to use additional means of protection. They are caught due to moisture contained in the air.

It should be noted that there are one-component compositions that have a small shelf life - about six months. Buying such paints, it is not superfluous to pay attention to this feature.

Powder and epoxy-polyurethane paints

We can distinguish another type of polyurethane products for painting - powder formulations. They are produced in the form of a homogenized mixture, the components of which are: pigments, hardener, polyester resin and filler.

This type refers to thermosetting dyes. They process the product or base, after which they are subjected to heat treatment, resulting in a reaction between the components that are fused with each other. The result of such work is durable and hard coating. That is why powder formulations are most often used for work in mechanical engineering.

Epoxy-polyurethane paint is highly resistant, therefore it is used in industry for processing various kinds of structures that are in contact with an aggressive environment to provide them with a good level of protection.

Application Method Classification

Also, polyurethane compositions can be divided into groups according to the method of applying to the surface:

- aerosol products;

- paint for which you need to use a roller or brush.

The first group of paintwork materials is used for metal products and surfaces. Automotive polyurethane paint in cans forms a uniform coating, on which there are no smudges and stains.

The composition that needs to be applied using a paint tool (brushes, rubber or velor rollers) is mainly purchased for interior decoration.

There are two-component polyurethane compositions for painting plastics - this is a basic water-based paint coating used for industrial painting of products.

Manufacturers: review and reviews

The main producers of polyurethane compositions for painting are Turkey, Germany, Greece and the countries of the former CIS. However, if there is a need to purchase polyurethane lacquer, enamel or paint, you can safely give preference to this issue of domestic products, since the paint coating materials consist of complex polymers that are successfully produced in Russia.

The trademark products showed themselves well in their work. Elakor, Krasko, Promtehsnab. There are no doubts about the positive characteristics of Russian paints and varnishes, since it undergoes thorough quality control, is certified and has all the permits.

Products made in China, no less popular in the market. It is represented by polyurethane compositions for painting cars, as well as for wooden and concrete bases, there is an excellent furniture paint in the range.

American polyurethane paint products represented by brand Valspar. The concern of the same name has been engaged in the manufacture of paints and varnishes for many years, the production of which takes place using the original technology of mixing coloring and binding components. The composition has a lot of positive reviews, because it is easy to apply, forming a thin and durable layer with a glossy or matte sheen.

This paint does not crack and does not contain unhealthy compounds. This product is used for painting machinery, metal structures, boats, as well as interior and furniture.

European company Milesi - a leader in the production of quality varnishes for wooden surfaces. Most furniture manufacturers prefer to use the products of this company, since the surface coated with polyurethane varnishes, has a good physical and chemical resistance and retains a beautiful appearance. Lucky Milesi can be used for all types of finishes, including doors and an array of MDF. Buyers note a large color range, which allows you to choose the desired color.

Paint products Sikkens Popular two-component paints for metal and concrete surfaces Redox. As a result of the use of this material, the painted objects, structures or bases acquire an excellent matte or glossy appearance.

How to choose?

To paint each type of surface requires a certain kind of polyurethane paints. In order to choose the right composition, you need to decide on the type of substrate for painting, as well as the characteristics of the room in which the work will be carried out.

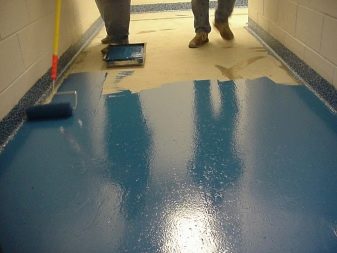

Paints for concrete flooring are used not only inside buildings, but also in outdoor conditions, which means that it is necessary to take into account the humidity of the air, as well as precipitation and the level of mechanical impact on the floor.

That is why the selection of the coloring composition is made according to the following criteria:

- humidity level;

- optimum terms of operation;

- intensity of mechanical impact on the surface.

The choice of paint for a wooden floor is based on the following characteristics of wood and coloring composition:

- features of wood;

- determines the intensity of the mechanical effect on the floors;

- The variants of paint compatibility with previous types of materials with which the surface was treated are taken into account.

For painting wooden bases will become an indispensable brush. For painting concrete, you need to use a roller, so that the coating will be even and smooth.

Polyurethane paints are much superior to other types of coloring compositions. Excellent appearance of the surface, durability and durability - the main advantages of this type of paint and varnish materials. Based on this, we can confidently assume that the range of such paints in the construction market will only increase.

You can find out how to paint concrete floor with polyurethane paint from the video below.