Balterio laminate: advantages and disadvantages

Laminate Balterio, produced by the same Belgian company, is quite popular in the global flooring market. The high demand for the product is evidenced by the fact that 97% of the production is exported, making the company confidently ranked second among European manufacturers in terms of total sales.

The main advantages of laminate flooring are the ideal ratio of price and quality, the vast experience of the company's specialists and a wide range.

Specifications

The “Balterio” laminate panel consists of a base layer made of chipboard, having a high density. Below is a paper, resin-impregnated layer, which plays a stabilizing role. On top of the main layer is covered with decorative, also consisting of resin-impregnated paper and patterned on it.Then the construction is laminated. As a laminator, PVC films are used, which provides a protective function and resists scratches, chips and dents.

Laminate is made from environmentally friendly raw materials and ISO9001 certified, which was awarded for high quality, safety and long service life. The level of excretion of formaldehyde and other hazardous compounds is ten times lower than that of analogs, which corresponds to the high Е1-class of safety. This was achieved thanks to the complete abandonment of the use of phenolic resins and chemical solvents. All production facilities of the company are located only in Belgium, which completely eliminates the risk of acquiring fakes.

In the manufacture of coating applied technology "Chrome Zone", which allows you to create an imitation of wood pores with such precision that it is almost impossible to distinguish laminated products from solid wood. The surface looks noble and natural in any light.

The design of the laminate includes special HDF platewhich is based on the company's own developments.It has high moisture resistance, fire resistance and the ability to resist mechanical stress. The coefficient of moisture absorption is 3 times higher than the indicators that are spelled out in European standards. The protective layer contains wax, which increases the water-repellent properties of the products. Panel lock Click express It is also a patented invention of the scientific and technical department of the company. It provides an easy connection of the lamellas between themselves and makes the surface of the floor visually seamless and very smooth.

The absence of gaps ensures that dust and moisture do not penetrate inside the coating, which significantly increases the operational life of the products. The unique locking system ensures high reliability of the web joints and their ability to withstand considerable mechanical loads.

Laminate has an anti-slip effect, which is provided by the technology of applying a multi-directional protective layer, and the formation of a micro-protector. Manufacturer guarantees perfect glossy laminated coating service for 25-33 years (depending on the model and operating conditions). Matte laminate is 10 years less.The high wear resistance class allows using such a coating in any type of premises with moderate load indices, including in conditions of high humidity. The surface of the panels is resistant to UV light and household chemicals, which allows you to maintain the brightness of color and clarity of the wood pattern during the entire service life.

Laminate plates have a density of 860 kg per cubic meter, which makes it easy to carry dynamic and static loads. Form stability and the absence of the risk of deformation is provided by the presence of protective melamine interlayers. This allows coverage to be used in schools and other spaces with heavy traffic.

High temperature resistant and compliance to EN14041 standard allows the use of laminate flooring with underfloor heating.

The presence of CE marking indicates the full compliance of products with all European standards of quality and compliance, and guarantees absolutely safe operation.

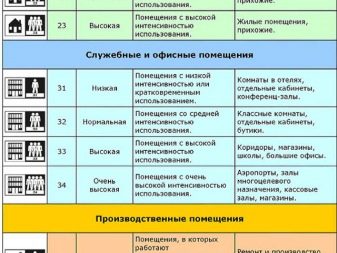

Kinds

Balterio products are represented by products of different wear resistance classes ranging from the traditional 31, to the highest 34 classes.The thickness of the panels varies from 7 to 9 mm, depending on the level of reliability and fire resistance parameters. Models 33 and 34 classes are able to withstand the action of water for 2-4 hours, while maintaining a good tightness of the surface, and not allowing water to leak under the laminate. Deformation of the plates and swelling of the entire coating is completely eliminated.

Models 31 and 32 classes do not have these characteristics, therefore, when operating them, excessive moisture is unacceptable.

According to fire resistance models are divided into three categories. Most products have indicators corresponding to "B" and "C" levels. This is the highest degree of fire safety, allowing the plates not to ignite when in contact with open fire. It is possible to achieve such high rates by using the technology of pressing under the influence of high pressure. The thickness of the laminate panels of fire-resistant models ranges from 8 to 12 mm, the average size of the plates is 126x19 cm.

Collections

Balterio offers over 150 different laminate models comprising 16 collections. The most popular and recognizable of them are the following:

- "Fortissimo" is a high-strength model used in places with high load.The slats are 12 mm thick, and the presence of a quadrilateral chamfer contributes to giving the floor a natural look that is difficult to distinguish from natural parquet.

- “Magnitude” is made using the “Chrome Zone” technology, which makes it possible to achieve not only visual, but also tactile complete resemblance to an array of natural wood.

- "Xperience Plus" is a laminate with a matte finish. Such models will successfully fit into hi-tech and minimalism, creating a volume effect in the room and visually expanding the space.

- "Impressio" - patinated models, are made in a wide range of colors, from bleached oak to black walnut, which allows you to choose a coating for any style and color of the interior. The application of the technology “Panoramic Design” ensures smooth transitions and the integrity of the pattern;

- “Tradition Sapphire” is a rather creative model imitating a poorly processed wooden plank. It will perfectly fit into non-standard and rustic interiors, will become the center of attention and perfectly refresh the design;

- “Grandeur” is an exclusive model, imitating an oak massif quite naturally. Possess a dull glossy surface, completely indistinguishable from the structure and color of the tree.Will harmoniously look in spacious rooms.

Styling Features

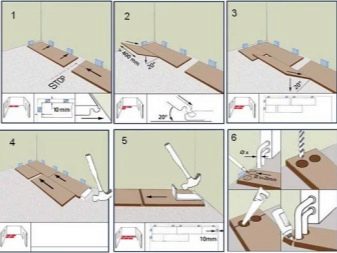

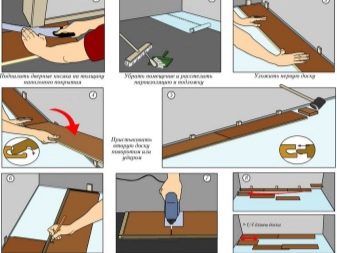

In order to carry out the installation of the coating yourself, you will need assembly instructions and the following tools: pencil, ruler, waterproof tape, handsaw or jigsaw. Before you start laying, you need to leave the panel in an unpacked form for two days, at a room temperature of 22 degrees and a relative humidity of 55%. This must be done to acclimatize the material during winter delivery at low temperatures. The next step is to proceed to the preparation of the floor, which consists in cleaning the surface and leveling the critical differences in height.

Then you need to lay a waterproofing material and the substrate, which are also manufactured by Balterio and have high performance properties. The sheet of waterproofing is laid with a small overlap on the wall, which is 5-7 cm. Between themselves the strips are glued with tape, while it is necessary that the edge of one piece overlaps the edge of another by 15-20 cm

After laying the soft bases, it is necessary to let them lie down for 5-8 hours, which will ensure smoothing of the material and eliminate the formation of creases and folds.

The next step will be laying laminate.Before embarking on it, it must be remembered that this type of floor covering tends to expand and contract under the influence of temperature changes, and although the numerical values of these changes are insignificant, it is necessary to leave gaps from 8 to 10 mm. Laying lamellae is recommended to start from the corner. The first panel is placed with a comb against the wall, and the second is screwed onto it with a groove. Thanks to branded locks, the process of making a number will be simple and does not require special skills.

The last lamella in the row is cut to size, and the remaining length of at least 25 cm is used to compose the next row. Laying the second is made from the place of the end of the first by inserting the panel into the first row and lightly pressing it. Next you need to put the next lamella on the ridge already laid, using a groove, then lift it at a small angle along with the previous lamella and fix it with the previous row. In this way the whole area of the room is laid.

Sometimes the installation is more convenient to start from the door, while laying the lamella of the first row along the doorway. In this case, under the floorboard, you must cut with a jigsaw and insert under the door frame, not forgetting the gaps.After installation, you need to cut off the excess waterproofing along the edge of the laminate and proceed to the installation of plinths.

How to choose?

Before buying a laminate, it is necessary to determine a number of parameters and requirements that apply to the floor:

- The first step is to determine the class of wear resistance. To do this, it is required to determine the intensity of the load and the probability of mechanical action. If the coating is chosen for the bedroom or living room, then we can limit the 31 or 32 grade resistance. When choosing a model in the corridor or the kitchen is better to choose the 33 class. The highest level 34 is used in public areas with a high pedestrian load and costs significantly more.

- Next, it is recommended to determine the level of humidity of the room, and guided by this parameter, choose a model. The best water-repellent qualities has a model 34 class.

When choosing coverage in children's and public institutions, it is recommended to purchase fire-resistant products with safety category "C". This heat-resistant coating does not sustain combustion and is ideal for heated floors.

- The next step should be to determine a comfortable price.This will narrow the search and ease the selection. The last step will be the choice of color, wood pattern and design of laminate, after which you can go to the store representative official dealers in Russia.

- It is important to take into account some of the shortcomings of products. Judging by the reviews of customers, this is the echoing of the coating, which occurs as a result of chipboard resonance, the unnatural materials and low moisture-resistant qualities of models of 31 and 32 classes.

Examples and options

Laminate "Balterio" looks very harmonious in any interior:

- A slightly patinated surface of a matt finish will become an original variant in modern minimalism. A successful imitation of a wooden floor with a clearly expressed knot texture will adequately decorate any modern style.

- The moisture proof model made with the help of the Panoramic Design technology is well suited to a country house. Natural woody pattern with smooth transitions of structure and tone will bring natural motifs into the interior and make the image of the room complete and concise.

- The successful combination of decorative window shutters, coffee table and laminate will give the room a special style and originality. The surface looks seamless and visually expands the space.

- Delicate shades and distinct contours of the slats and wall panels emphasize the geometry of the space and bring notes of peace and harmony into the interior of the bedroom.

- The original design with an imitation of rough woodwork and an emphasized discrepancy in the pattern of wood fibers between adjacent plates will add variety to the interior and attract attention.

For information on how to lay Balterio laminate with ClickXpress locks, see the next video.