Vinyl laminate: advantages and disadvantages

Approaching the question of what kind of flooring will eventually be laid, everyone is trying to choose a material that lasts a long time, will look spectacular, will not suffer from accidental drops of heavy objects or sharp pet claws. It is easy to choose such a coating, you just have to pay attention to the vinyl laminate.

What it is?

Vinyl laminate is a fairly new finishing material that appeared in Russia about 10 years ago. Despite his “youth,” according to some of his characteristics, he overshadows his floor-standing counterparts — laminate, linoleum, and parquet.

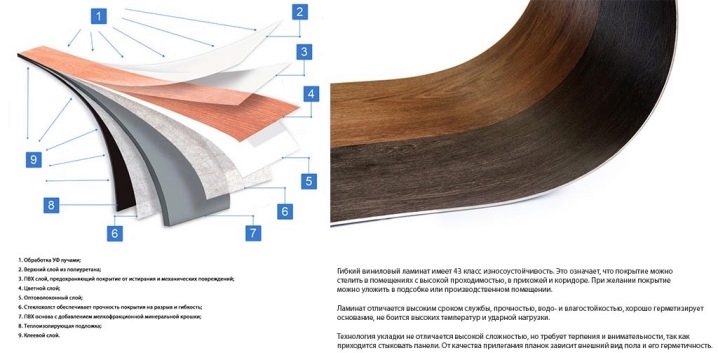

In fact, the panels consist of several layers. They can be divided into two parts - vinyl base and protective layer. The basis is a strong balance layer of polyvinyl chloride (PVC or vinyl) with various additives, for example, quartz. There are vinyl layers on the bottom and on top of the base, but they are already mixed with fiberglass.

After that is the base layer, which is glued to the paper decor. The paper is covered with polyurethane, and sometimes with additional vinyl. Many of its characteristics depend on additional impurities in the composition of the vinyl laminate. The laminate treated in a special way can even be used in the control rooms and operating rooms.

Polyvinyl chloride is a product of oil refining. Its main property is durability, it practically does not decompose. Because of this, this material can often be found in siding, lining and packaging materials, window profiles, hoses, plumbing. PVC is quite eco-friendly material.

Despite the entire chemical history of its creation, it practically does not emit toxins, only with prolonged heating. Therefore, such a laminate is not recommended to be laid near fireplaces and stoves.

Kinds

According to its characteristics, such a laminate can be both 23 classes and 43. Naturally, properties of such products will be different:

- The simplest and cheapest options are slats of 23-31 class, which can be laid in rooms with low traffic (at home, in the bedroom, for example). But such panels are unlikely to last more than 5 years.

- For home, professionals advise choosing a laminate of a class above 31, the so-called semi-commercial and commercial vinyl laminate.

- The covering 43 classes stack in gyms or on production.

Vinyl laminate is also divided into regular, self-adhesive, Contesse and quartz vinyl:

- Ordinary PVC laminate panels consist of a base and the front side with imitation texture. Along the edges of the lamella there are projections on which glue is applied, or they are with a locking compound. The panels are simply glued to each other or fastened like a regular laminate with a chamfer.

- Self adhesive Laminate can be used where previously its counterpart has not been used - in bathrooms and basements. Along the entire perimeter of the panel there is an adhesive layer with which the lamella is installed. It is enough to remove the protective coating.

- Contesse - unique vinyl material. It practically does not react to water and aggressive detergents (for example, bleach or other disinfectants).In addition, it is not exposed to sunlight, it does not catch fire and is able to withstand increased loads.

- Quartzvinyl The laminate contains porcelain stoneware particles. It is also heavy duty. The manufacturing process uses Nano Silver technology. It contains silver ions, which, as you know, will have disinfecting and anti-bacterial properties. It is such a laminate is recommended in the halls and operating rooms.

PVC laminate can imitate the floorboard, as well as its "brothers" laminate or linoleum, and maybe - a stone pattern. Usually imitating stone surfaces are presented in the form of square tiles. Imitation of finishing materials is quite high, many say that the laid vinyl laminate is very similar to parquet, both visually and tactilely.

Dimensions and structure

PVC laminate outwardly can strongly resemble its counterpart, their slats are very similar, even in size. There are two options for panels: 100 * 920 mm or 180 * 920 mm. There are also offers in the market in the form of a vinyl laminate in the form of a square tile, the side of which can be from 300 to 600 mm. The layer of vinyl on one lamella is from 1.5 to 3 mm, that is, the thickness of the panel itself will be from 6 to 8 mm. The last figure corresponds to the laminate class 31-32.Less common options with 5 mm PVC coating, with the thickness of the panel will be from 10 to 12 mm. Accordingly, the thicker the panel, the closer it is to the 43 class of durability.

Plastic laminate - quite flexible material. This is achieved due to its layered structure. But the main "blow" in the field of its operation falls on the upper protective layer. The thicker it is, the longer the coverage will last. The most unscrupulous manufacturers (who usually sell the cheapest products) make the most minimal layer of polyurethane coating with the addition of aluminum oxide 0.1 mm thick, and if the sheeting cut is 0.5 mm, then this material can also be laid in public places.

Manufacturers who are concerned about the quality of their products, use in their coverage polyurethane with ultracomponent (UV) and ceramic chips - this covering belongs to the last, fifth generation of materials.

Lamels coated with such a composition are considered the most wear-resistant.

Advantages and disadvantages

Vinyl laminate is rapidly gaining popularity as a finishing material. For many, the advantages in using and finishing the floor outweigh its disadvantages.Plastic laminate has established itself as a material whose properties greatly exceed the characteristics of similar materials, and it can be placed where there are contraindications for ordinary laminate. The advantages of PVC panels are as follows:

- High wear resistance and long service life;

- Compatible with the system "warm floor", has good thermal insulation properties;

- Sound insulation at the proper level;

- Easy to clean (not afraid of water or detergent);

- There are many colors and structures that can be inscribed in any interior;

- A clear and simple assembly principle, even a non-professional can handle.

Despite the abundance of advantages, the material has disadvantages:

- It is worth remembering that PVC panels with prolonged contact with heat (with high rates) can begin to emit harmful substances, so they are not recommended to be laid near fireplaces and stoves.

- With direct, direct exposure to sunlight, the material changes its color, turns yellow and burns out.

- Also, do not use in a room where the vinyl floor is covered, rubber mats and walking in rubber boots or slippers with heels.PVC is “not friendly” with rubber, there are spots that can not be removed later.

- Truly high-quality vinyl laminate belongs to expensive materials. Although this is a controversial issue. If all aspects are taken into account (dismantling of the old coating, preliminary work, leveling the floor and the floor itself), the installation of PVC panels can cost the same price as the installation of a conventional laminate.

- If the surface of the lamella is still damaged, then this can not be fixed. Only its complete replacement is necessary.

Comparison with other coatings

When choosing how to arrange the floor, each is guided by their own considerations. For some, the price-quality ratio is important (and it is desirable that the price be minimal), for some it’s important how the surface looks in the end, its stylistic basis, someone looks at how the floor will work (how often its it is possible to wash, whether the feet on such a coating will freeze, whether there will be allergies, whether they will stand on end or whether they will blow on bubbles, if neighbors are flooded with water).

In this matter, each one builds his own rating of floor coverings, taking into account one or other advantages of the material, noting its disadvantages.

In many of its characteristics PVC tile or lamella is better than their counterparts, and take first place. Vinyl floor is considered expensive, but this is in comparison with inexpensive models of laminate, linoleum. But the floor, self-leveling floor can argue with him in the issue price. In addition, many types of coverage require an ideal aligned base, preliminary preparation, which undoubtedly adds to the total cost of the floor. Plastic laminate, like linoleum, can be laid directly on the old coating, as long as it is smooth, with no obvious transitions. Experts say that you can lay such a laminate when moving up to 4 mm.

Vinyl is a moisture resistant material, it is almost 100% resistant to water. Few materials can boast that it can withstand prolonged exposure to water, and there will be no consequences - no bubbles, no swollen boards, no stains or stains - except ceramic tiles, some types of linoleum.

Many modern materials have a chemical nature, and as a result emit harmful compounds. Allergy sufferers and asthmatics are critical in this regard to the choice of material. It is believed that PVC does not emit any substances, except with strong heat or exposure to various reagents.By the way, natural flooring also does not emit toxins, in contrast to cheap synthetic linoleum. In this way, vinyl flooring is environmentally friendly.

An important factor is the durability. Here PVC laminate is high enough. There are such vinyl flooring, the service life of which can reach 20-30 years, and at the same time such a coating will be washed, perhaps even with potent detergents. PVC laminate, like stone, with such treatment will be nothing. Modern materials, for example, linoleum or simple laminate, do a good job with the design task - imitating natural or expensive flooring: parquet, stone, marble, tile. Sometimes they can even be confused.

But in this regard, plastic laminate still “holds the palm”: in its assortment there are lamella a la parquet, marbled or stone tiles.

Installation

PVC tile is very easy to install, regardless of what type of fastening is present on the panels - lock joint, partial or full adhesive coating. The locking connection is the same method of fastening as on the lamellae of any laminate coating.

Ways

There are several options for installing PVC tiles. It all depends on the type of flooring:

- The classic way. It is used when using laminate with a lock. In order to connect the panels, it is necessary to insert the grooves into each other and snap them. Further, as if collecting a puzzle, all other floor keeps within.

- Glue mounting. It is rarely used, since special formulations are needed. But this method is quite "tenacious" if you need to lay vinyl, for example, on the wall.

- Laying slats with adhesive tape. The adhesive coating is located on the edges, at the ends of the panel. It replaces the lock. Slats are laid in the same way as ordinary laminate, only they do not snap into each other, but stick together.

- Plastic laminate with adhesive backing is laid directly on the floor itself. Glue is located over the entire area of the panel. It remains only to carefully stick the slats one after the other.

Instruments

Depending on which PVC laminate is installed, you will need the following tools:

- The way the package will be cut, the lamellae (a sharp knife, scissors, a saw);

- Spacers limiters to cover "did not run away" ahead of time;

- Pencil, ruler (or measuring tape, building tape measure);

- Light hammer;

- Scotch;

- If necessary, a special adhesive composition.

Assembly

Preliminary preparation of the floor before laying the vinyl floor is not required, except in cases where there are significant transitions on the floor. Then it should be pre-aligned. Before laying the lamellae, it is necessary to clean the future working surface - dirt and dust should not be present. If PVC laminate will be laid on the "warm floor", you should first turn it off for a couple of days, but make sure that the temperature in the room does not fall below the mark of 18 degrees. Otherwise, you will need a construction dryer - it will be necessary to heat the lamellae during the installation process.

Before laying the floor is necessary make measurements of the room and plan the layout of the panelsespecially if there will be a decor or pattern. It is also desirable to install the slats parallel to the direction of light. Before laying vinyl, he must “acclimatize”, stay indoors for 1-2 days. At this time, it is not necessary to open the packaging with lamellae. So they will be better protected.Slats need to get and check just before laying.

As a rule, plastic laminate is laid in the so-called "floating" way. The panels are not fixed to the wall, there is a small indentation of a few centimeters, the lamellae are stacked "in a run-up", that is, the second row begins not with a solid plate, but with a trimmed part. It should not be less than 30 cm. The installation of lamellas starts from the corner.

The first three rows are basic. The width of the panels in the last row should not be less than 5 cm. If necessary, you can make the first row more narrow.

Manufacturers

On the market you can find vinyl as high, so low quality. Judging by the reviews of buyers, slabs of pioneers of production from Belgium have proven themselves well, although other manufacturers are not lagging behind and offer the most varied products for every taste, color and wallet. The most popular vinyl laminate manufacturers on the market are listed below:

- Quik Step. One of the leading Belgian flooring manufacturers offering affordable and certified Livyn PVC laminate.

- Allure Floor. It occupies a leadership position. Very popular expensive brand.

- Tarkett. There is production in Russia, which increases its availability to customers, in particular, the specially created brand Polystyle.

- Vinilam. Pioneer in the manufacture of vinyl. Many even call PVC tile vinyl from the name of the company.

- Haro. Offers expensive high-strength material.

- Allur. Chinese manufacturer, characterized by an unusually decent quality and high prices.

- IVC. Known for the Moduleo. Produces a plastic laminate with a locking compound. Product prices are different. Also mention AquaFloor, Fine Floor, Holzplast, Egger, Pergo, Barco.

How to choose?

Each room is a separate world in which there are "laws" for sex. When deciding what kind of PVC tiles to cover the floor in an apartment, you must first take into account the functional of the room: what is its permeability, how quickly it becomes soiled, what are the conditions of humidity and room illumination. Living conditions in the bedroom are significantly different from the kitchen and hallway.

For corridors and hallways suitable models of vinyl with a high degree of durability (from 32 classes). Still, these are walkthroughs that need to be washed frequently. The floors in the kitchen also need to be washed frequently, moreover, the permeability here is also not small - decent wear resistance is needed.

For the bedroom are important insulating and sound insulation properties. Vinyl in this regard - fertile material. You can even try to choose a coating with an interesting and conceptual design.

For a bathroom, a toilet it is necessary to pay attention to the moisture resistance of the material. It is best to choose quartzvinyl or Contess coating. If you decide to put PVC on the balcony, then the room should be closed - the material reacts poorly to direct sunlight. Otherwise, it will last a long time and will please the eye for more than one year.

Choose a vinyl flooring in the apartment, it is worth starting with 32 endurance classes. Smaller classes, as it were, are intended for home use, but, as a rule, such use is rather limited in time, with a maximum of 5 years. Choosing a plastic laminate, do not be stingy, cheap options are not as reliable as proven more expensive models.

Unscrupulous manufacturers may overestimate the parameters on the packaging of plastic laminate. As for the design, the PVC market is now so diverse that it can fit into almost any interior.

Examples in the interior

Vinyl laminate has a lot of variations of color, texture, floor covering material. Imitation of various wood species is simply amazing, they are painted almost in all colors of the rainbow: bleached oak or noble wenge, light ash or morengo. There are a lot of models with a pattern of stone - noble marble, ceramic tiles, and even for the most demanding taste there are models that imitate animal skins (for example, zebra) or weave fabrics.

For the designer of this kind of material - a real find. In addition to its practical properties, it has a huge aesthetic appeal. Despite the fact that PVC is considered a new material in the industry, it is increasingly gaining popularity and more and more often it can be seen on the floor in apartments and houses.

Due to its texture and simplicity in laying vinyl "captures" an increasing space. The bedroom, bathroom, kitchen, hallway - the floors are no longer enough here, and the vinyl panels "migrate" to the walls and ceiling. It is quite possible to make marbled walls and put wooden floors in the bathroom if all this imitates plastic laminate.

Vinyl laminate is an excellent choice of a practical owner who cares not only about the comfort, but also the beauty of his home. PVC as no other material combines aesthetics and functionality.

In the next video you will find step by step instructions for laying vinyl laminate.