Faceted laminate: features and specifications

Today laminate is considered the most popular flooring. If you are going to purchase it for your cozy home, buyers often meet in the building materials stores a laminate with a facet previously unknown to them. In order to make the right choice, you need to carefully study this type of coating and its characteristics.

What it is?

A small cavity is called a facet in the place where two laminated boards meet. Such indentations are obtained by pressing during production. This type of products on the market of building materials appeared relatively recently.

Many people, choosing laminate, think about why chamfer is needed:

- First, the presence of a bevel makes the product very similar to expensive parquet. And therefore, designers are able to embody a variety of ideas using laminated panels with a chamfer in a modern interior.

- Secondly, when such products are made with beveled edges, they are impregnated with special means and covered with protective materials, thus preventing them from contact with moisture. Ordinary panels without chamfer are not protected by this.

For laying laminate need a secure fit. Interconnected panels must withstand various loads.

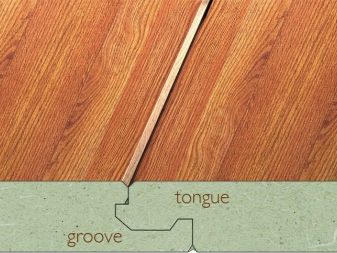

When the first laminated coatings appeared, they were fastened with glue, but after a while the glue dried up and a complete replacement of the product was required. Now the boards are connected by locking systems, which made installation faster and more practical.

Therefore, choosing laminate, need to carefully examine the locks. Currently, the lock system Lock is the most popular and inexpensive. When using these locks, the panels should be installed at the end with a hammer when installing, until the gap between them is eliminated. Despite the ease of installation, such locks have their disadvantages.During operation, friction occurs in the lock system, and because of this, floor coverings quickly deteriorate and gaps form. Coverings with such a lock can not be dismantled.

The most modern and convenient castle system - Click. It connects the panels by snapping the lock. To do this, a panel with a chamfer at an angle of 40 degrees is carefully inserted into the groove and lowered onto the floor. When bonding occurs, a click is heard. These locks are very reliable and durable to use. The great advantage of such products is that they can be repeatedly disassembled and assembled without causing any harm. To protect any lock system, it should be treated with a sealant.

Advantages and disadvantages

Buyers before purchasing flooring should be aware of all the positive and negative aspects of laminate with or without a chamfer. Consider below the pros and cons of having chamfers in laminated panels.

The main advantages include:

- constant loads, differences in temperature and humidity contribute to the appearance of cracks and other defects through time on the coating of a simple laminate; products with depressions will have unevenness almost imperceptible;

- laminate with chamfer looks like a coating of solid;

- the presence of recesses does not adversely affect the coating elements;

- laminated panels with a chamfer, depending on the direction of installation, can visually expand the space of the room;

- well absorbs load;

- long service life;

- the possibility of laying such products is not on a completely flat surface.

The disadvantages include the fact that the laminate with a bevel price range abovethan normal.

It is believed that dust and dirt collect in the grooves, but this is just a myth, because the depth of the groove is small.

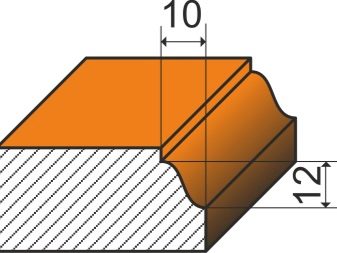

It is also believed that the beveled edges are not strong enough and therefore surface can not withstand the load. But this is also an invention, since the chamfer is applied to products with a thickness of 8 to 12 mm.

Kinds

The modern market is represented by laminate with double-sided and quadrilateral bevel. In the first version of the recess only from two sides of the board, and in the second - from all four.

According to the method of application, the following chamfers are distinguished:

- curly. By trimming the pieces, the chamfer is shaped. In this case, the edges are polished to achieve a perfectly smooth finish.The figured structure will give the floor a look of natural wood coating;

- rolled Special rolling rollers squeeze out the necessary bends.

The shape can be noted 2 types of chamfers:

- V-shaped. Bevel at the edges of a straight line. A Latin letter V is formed at the junction of the panels. The depth of the groove is up to 3.5 mm;

- U-shaped. In this case, the chamfer is rounded. The groove is shallow - about 2 mm.

Classic chamfer appeared one of the first. It is quite deep.

By treatment option exists:

- laminated chamfer. It is durable, but expensive. Reliably protects against external factors. Rarely used for v-shaped cuts (with the exception of European premium class laminates), often for U-shaped;

- painted chamfer. Apply a special coloring agent to visually enhance the effect of the deepening. Wax and other protective materials are usually not covered.

In the shops you can also find brushed laminate. Its surface is treated with a metal brush and then varnish is applied. This coating is most similar to natural wood.

Laminate with a chamfer can only be single-sided, but the width of the panels can be different.

Characteristic

Laminated panels for chamfering should not be thin (optimal thickness - 8, 10, 12 mm). This is due to the fact that the strength of the flooring in the places of the recesses is markedly reduced. And if for example, put a heavy table with iron legs on a thin laminate, then it can be deformed. For this reason, manufacturers for chamfering choose boards with a certain thickness.

Laminate with a chamfer is wide and narrow. The average width of a strip of narrow laminated panel is 9–15 cm, and wide - 18–19.8 cm.

The narrow laminate with a facet is ideal for rooms with a small area, but it will also look decent in large rooms. Outwardly it is very difficult to distinguish it from natural parquet boards. Using narrow laminated panels, you can bring to the interior uniqueness and unique style.

Colors

Choosing the color of the laminate, it is important to consider certain nuances. The color palette of the flooring and doors in the room must be identical and in harmony.The best color of the laminate is the one that fits the intended style of the room.

Many believe that the floor is a light color in need of some special and meticulous care. In fact, this is absolutely not the case. If you buy white laminate, cleaning will not be longer and maybe, on the contrary, it will decrease in time, for the reason that there is less visible dust on the light floor than on the dark surface. The most popular among buyers are colors - bleached oak and light oak.

The white color of laminated products with grooves is often used in rooms in the style of hi-tech and French Provence. Gray laminate is great for loft and futurism. Thanks to the bright flooring, the space is visually expanding. Also light panels with a facet are made with an invoice for a natural board, a stone and with imitation of artificial aging.

Laminate neutral colors are made to look like solid wood. This option is suitable for all stylists and remains fashionable at all times. It is actively used in apartments, houses and other objects.Using classic laminated panels, you can change the style of the room in the future without dismantling the coating. This option is unpretentious in the care.

Laminate dark colors ennobles the room and emphasizes the aristocracy of the owners of an apartment or house. Suitable for indoor use in classic style. All black laminate is perfect for hi – tech and Japanese style. The dark coating with a light chamfer looks advantageous and unusual. It is recommended to wash the dark floor using special means to prevent the appearance of streaks on the surface.

Multi-colored laminate looks bright and very unusual. This type of coating is often put in stores and offices. It is also suitable for the decoration of the children's room.

Styling methods

Ways of laying laminate with a facet are many, and they are similar to those involved in laying simple laminated panels. It is possible to mount panels along, across, diagonally and figuratively (diamonds, herringbone).

Laying the cover across the room visually expands it. Stacked boards along, lengthen the room.

The diagonal method is original and allows you to emphasize the characteristics of the floor.Diagonal styling also visually increases the size of the room. Using this method, the consumption of materials increases by 10-15%.

Installing laminate with a chamfer, when the joints are displaced against sunlight, contributes to the visual separation of each seam.

When installing laminate with bevelled edges, you need to follow some rules:

- for tight fastening of panels it is necessary to use wooden bars and a rubber hammer (or any soft);

- each row of laminate must be wedged;

- doors can be mounted only after the work with the floor is completed;

- Install baseboards preferably with a width of at least 20-25 mm.

Selection rules

Choosing a laminate with or without a facet, you can see that there is no significant difference in the price range, methods and technology of installation. But it is important to remember that coatings with indentations still have a large number of positive and significant differences.

Today laying of the laminated covering becomes more and more popular. to the ceiling. For the ceiling you can buy a laminate with a large bevel. This option will look original in rooms with high ceilings.

The quality of the panels and their manufacturer is what every customer should pay attention to when choosing products. The producers of good laminate always have documents confirming their high quality. And the rest should be based only on their own preferences.

Care

For any product you need to take care and follow the rules of operation. Laminated bevel is also no exception. Especially you need to take care to cover when rearranging furniture and in contact with shoes with heels.

Chamfer panels before wet cleaning recommended pre-vacuumingto get rid of possible dust in the grooves.

It is necessary to care for this type of coverage with non-abrasive products to preserve shine and aesthetic appearance longer.

To get rid of scratches or other defects on the laminated board, you can use a wax pencil. He will easily restore the surface. To protect the floor from moisture and dust, you can treat the floor with mastic or emulsion.

Once in 8-10 years laminate for renovation must be varnished or fluffed with oil.

Brands

A large number of Russian and European companies are engaged in the production of laminate with a facet. Below are the most popular manufacturers:

- Pergo. One of the most famous European manufacturers of flooring. Their products are environmentally friendly, easy to operate, equipped with PerfectFold ™ 3.0 unique locks. Laminated panels have a variety of colors and textures;

- Quick step. The Belgian – Russian company produces a huge number of laminated panels from classic to trendy models (marbled, leather). Coatings of this brand are known for a variety of sizes of boards of 31-33 strength class, resistance to the appearance of defects, as well as a long warranty period;

- Tarkett. This manufacturer has a huge selection of laminate with a chamfer with good technical indicators, but the price of manufactured products is somewhat overestimated;

- Kronostar. This company produces laminated coatings 31-33 resistance class at an affordable price. Products are equipped with two types of locking systems, have a standard size of products;

- Balterio. Known in the market of building materials as manufacturers of one of the most durable and resistant laminated coatings of 32-34 wear resistance class.Products of the brand are distinguished by beauty and naturalness, rich color palette, excellent technical characteristics;

- Ritter. The company is a manufacturer of original laminated coatings with imitation only for natural leather. Produce panels 33-34 class, with a warranty period of up to 30 years;

- Egger. Produce panels for the floor and walls, warranty up to 25 years. Under this brand is made quite expensive products.

Unusual interior solutions

Laminated bevels are often used by designers to create unusual solutions in the interior of an apartment.

The coating with imitation under the stone in the living room and kitchen looks original and stylish. Such panels are much warmer than stone floors, so there is no need for additional heating.

In the bedroom, you can use bevel panels not only on the floor, but also smoothly moving onto the wall.

To make the nursery bright and stylish, designers offer a multi-colored laminate flooring.

Looks beautiful white flooring in combination with white doors and bright accessories.

Braided laminate with a quadrilateral chamfer will make the living room more stylish and nobler.Also, brushed panels are ideal for the design of the cabinet.

In rooms in which the windows are not in the center, you can use a wenge color coating with a four-sided chamfer. It is mounted regardless of the direction of the sun's rays.

On how to lay your own laminate flooring, you will see in the next video.