How to glue linoleum?

Linoleum - one of the most popular and economical ways to finish the floor. This material retains heat well, is able to fit into any interior and is very easy to install. However, you need to know some of the rules and features of the installation of linoleum to make a truly stylish and high-quality repairs.

Advantages of adhesive mounting

The main thing that distinguishes linoleum from the spectrum of all finishing materials for the floor - its simplicity. This coating is appropriate in rooms with high humidity, because the artificial material does not pass and does not absorb liquids. In addition, it is durable and wear-resistant, so it is suitable for public institutions and just rooms in which there are a large number of people. These qualities make linoleum a perfect floor covering. However, in order for all its advantages to be realized in practice, it is necessary to firmly secure the material on the surface.

Adhesive mounting is the most preferred way to install linoleum indoors. Experts point out several key factors that determine this choice:

- The appearance of waves on the surface of the coating. Linoleum can be laid in a non-adhesive way only in small rooms up to 10 square meters. m. However, there is no guarantee that after a while, the coating will not start to wrinkle. This is due to the deformation of the elastic material, which is not fixed to the surface. This process cannot be stopped, as it is impossible to get rid of ugly waves, which not only spoil the appearance of the room, but also are simply inconvenient for residents. Saves only hauling all coverage. And you can initially install high-quality linoleum in a good and correct way. Then the coating will bring joy for many years. In addition, if the installation process requires putting a few strips of linoleum, for example, in a large room, then adhesive mounting is the only acceptable option. Only he is able to prevent the spread of linoleum seams and surface distortion.

- Shrinking linoleum over time. Very often, when the material is laid in the usual way, that is, without fastening, ugly cracks appear at the joints near the walls or in the doorway. They are caused by the fact that linoleum loses moisture over time, becomes more rigid and decreases in volume. Laying the cover with a margin is not possible, so it is better to fasten it around the perimeter and at the joints so that the need for repair does not arise as long as possible.

- Reduced lifetime. Due to the presence of air under the surface of loose linoleum, it is much easier to accidentally break it. In addition, it tends to curl at the joints or thresholds, which not only looks awful, but also represents a potential danger, because it is easy to trip over the edge of linoleum. Therefore, repair specialists recommend to always install the linoleum with glue. They also note that this technique can significantly extend the life of the coating.

- Efficiency. Linoleum itself is inexpensive. The same applies to its installation tools: adhesive compositions are available to any wallet.

All this makes the adhesive installation of this type of coating the most preferred option.However, it should be noted that this method has a drawback: the linoleum installed in this way will not be easy to dismantle.

On the other hand, with properly selected and glued linoleum, the need to change the coating will disappear for a very long time.

What can you stick?

Choose the type of glue you need based on the type of linoleum, because this material may vary in the recipe, and then you need different types of installation. So, first of all, we can distinguish two types of glue:

Dispersive

This type of adhesive composition is suitable for domestic and semi-commercial linoleum. This group includes: acrylic solution, water suspension and cellulose glycolic acid:

- Adhesive type bustilat intended for bonding linoleum with the effect of insulation and dense texture.

- Acrylate has a particularly high strength and is suitable for rooms and corridors in which a large number of people happen every day.

For offices where there are a lot of computers and other office equipment suitable conductive type of glue. Bitumen mastic is usually mounted on a fabric-based coating. This is a particularly good choice for residential premises, because these compounds are non-toxic and environmentally friendly, so they do not pose a danger to people and animals.In addition, these compounds are very elastic, which means they keep for a long time and prevent the deformation of the coating.

They have certain disadvantages. The main one is low resistance to cold. It will not be possible to store the remaining glue on the balcony in the winter, because under the influence of low temperatures, the glue loses its properties. In addition, these types of glue - not an option for rooms with high humidity, otherwise the positive effect of the repair will not last long.

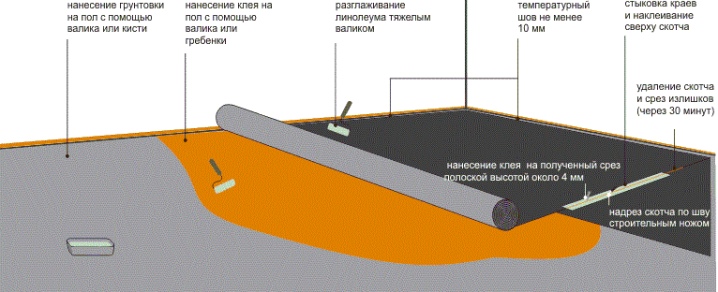

Before applying the adhesive, the coating must be carefully leveled. The floor is covered with glue using a spatula with cloves. For a strong coupling of a linoleum cloth with a floor, the layer should be at least 0.5 cm. The linoleum neatly laid on top should be carefully and evenly pressed.

Roller need to expel excess air. Particular attention should be paid to the edges, so that later they do not peel off and do not cause problems.

To calculate the adhesive consumption for a specific room, you can use the information on the packaging.

Reactionary

Unlike the previous group of adhesives, these compounds are very toxic, endowed with a caustic unpleasant odor. They are explosive and flammable.These compounds are usually used to handle problem areas: joints and edges. They are available in three types, labeled with letters of the alphabet, and have a higher cost compared to dispersive types of glue.

The reason why many repair technicians choose this particular type of glue is because of the highest strength of the result. Adhesives of this type are also called “cold welding” because, when they come into contact with the linoleum material, the substances contained in the adhesive start a special chemical reaction that dissolves the surface of the linoleum, firmly fixing it to the floor.

Type A glue is used for welding seams. It has a liquid consistency and is available in special tubes with a sharp nose, so it is quite easy to use. Ideal for residential and commercial coatings. The resulting seam is transparent and completely imperceptible from the outside; therefore, the joints of the coatings in the room are well treated with this type of substance.

The next type of reaction glue, C, is different in consistency: it is white and thicker. It is used for the restoration of the seams of old linoleum, that is, to close up the resulting ugly cracks.When working with cracks you need to remember first of all to clean them from dust and small debris. Then it is necessary to paste over each edge of linoleum with building tape so as not to disfigure the coating with glue.

It will not work then simply wipe with a cloth in case of contact with the material. It will be necessary to wait for the glue to harden to remove it with something sharp. But the trace, most likely, will still be noticeable, so it’s better to avoid it. Full curing of the adhesive occurs 50-70 minutes after the application of the substance. Then you can remove the protective adhesive tape.

Type T is preferred by professionals. It is used for finishing joints and the rules for working with it are the same.

Double-sided tape is used as a substitute for glue in small spaces. It serves to fix the material in several places, and the baseboards complement the effect. This is a controversial question, which way is better in rooms up to 20 square meters. m, however, the general trend is that non-adhesive methods gradually outlive themselves.

Do I need to glue the product?

Sometimes tenants or owners of premises ask about the appropriateness of using glue when installing linoleum not on top of a concrete screed, but on materials such as hardboard, particleboard, OSB and fiberboard.These slabs, as well as, for example, wooden floor and crumbling concrete, are not the most durable and reliable basis for laying linoleum strips. They are unstable in terms of microclimate, as they can accumulate dust and moisture. Therefore, in such a situation, the application of glue is prohibited;

In general, it is necessary to take into account that all types of glue are applied only on an absolutely flat, thoroughly cleaned and prepared surface.

Making the right laying with sizing on the floor

It is correct to apply glue only on the prepared surface, for example, on a fresh bulk floor. Experts unanimously argue that this is an ideal option. But sometimes when repairing is too problematic or there is no time to remove the old floor. Therefore, very often linoleum is laid on a wooden floor or parquet boards.

To fix this coating to the tree is very problematic., because between the boards, especially if they are old, gaps can form. And the material itself is usually not very smooth, which can affect the appearance of the linoleum surface, even after a while.The result of gluing linoleum to painted boards can be especially unfortunate. Both the colorant and the glue contain chemicals that, when reacting, form on the outside ugly spots that only get worse with time. In this case, it is not recommended to glue a piece of linoleum, it is better to choose other methods, for example, nails.

Partially solves the problem of irregularities sticking to plywood. A piece of coating can be put on top of old boards and linoleum can be glued to plywood. It is necessary to control the size of the boards so that they fit snugly against the walls and between themselves and form a stable base for the future floor. Making sure that all conditions are met, and linoleum is also suitable in size, it can be glued.

Sometimes in the process of repairing the question is solved whether it is possible to lay a new linoleum on top of the old one without removing it. Some believe that in this way they create an additional substrate for the new coating, and also save themselves from having to agitate the old dirt. This option is especially tempting if the old coating looks relatively good and does not have pronounced waves and irregularities.

In part, of course, they are right. Nevertheless, it must be borne in mind that under the surface of the old linoleum often accumulates dust, dirt, and at high humidity mold and fungus can occur. All this will affect the new linoleum and prevent the creation of a healthy atmosphere in the room, so it is better to remove the old coating and clean the place of application of the new one.

If it is decided to cover the old floor with new linoleum, then you can either lay it on the old layer, fix it with baseboards and furniture, and use glue. It should be suitable for the type of linoleum and applied evenly around the perimeter.

Do not forget about the special technologies of sealing seams, if the room is large and several strips of material are superimposed.

How to glue to metal?

Sometimes it is necessary to fix the linoleum on completely different surfaces, for example, on metal. Many people choose in such cases, double-sided tape, because it is quite firmly glues linoleum and do not have to bother with the application of glue. However, this method has several disadvantages. Double-sided tape does not provide proper coupling with such a complex surface as metal, therefore,after a while, it will surely shift, and waves and creases will appear on the outside of the linoleum.

In this case, liquid nails, for example, Moment glue, are considered the most successful method of gluing. This is a modern method of mounting coatings, which allows you to attach them to almost any material and guarantees high fixing strength. Liquid nails are not used in working with natural materials, however, they are quite appropriate when interacting with all the others. So, to fix a solid piece of linoleum on a fabric basis, they will not work, but they will cope with materials such as PVC. In addition, they are very economical: they do not require application to the entire surface, several snakes are enough.

Before applying the glue, as always, you need to make sure that the surface is prepared for gluing: smooth and unpainted.

But in the case of this material, you must be prepared for the fact that linoleum in these places will quickly wear out.

What is the best way to glue the edge?

At the risk of choosing a floor covering material such as linoleum, there are always edges, joints between the strips, as well as between the material itself and the wall or threshold.Fortunately, modern technologies allow the use of chemical compounds that securely seal the seams and fasten the edges. This is, of course, about special types of glue for sealing seams, which most often act on the "cold welding" technology.

To securely fasten the edges of the new coating or to restore old seams, it is enough to fill them with a syringe. They are very easy to use.

It is enough to observe the usual safety rules: to prevent the ingress of glue into the eyes and mucous membranes, not to store it in flammable places and to ventilate the room well.

Examples and options

Usually glue is selected depending on the type of linoleum. There are, however, several brands of adhesives that are more versatile and are suitable for almost all types of coatings:

- Among them, the Forbo 525 Eurostar Basic. This glue can be used when fixing linoleum on a variety of surfaces. It has an average consistency in liquid, therefore it is easy to apply with a spatula. In addition, it is very durable and suitable for work even in difficult areas.

- For cold welding seams, you can apply glue brand Linocol. It boasts a lot of positive feedback due to its ease of use and secure attachment.

Learn more about how to glue the linoleum, you will learn from the following video.