Substrate under linoleum on a wooden floor

In the construction of a dwelling or in the repair of the arrangement of flooring involved in the last turn. This is done because, upon completion of the installation and finishing works, the floor space is no longer subject to mechanical stresses associated with the transfer of building materials, tools and ladders, and also cannot be stained with paints and other coloring matter.

Of the variety of materials for finishing the floor, linoleum is one of the most inexpensive, and the variety of colors and prints on it makes it possible to satisfy any customer's needs. However, such a floor covering may require laying additional material under it.

Coverage Features

A variety of types of linoleum allows you to choose it for any style of your interior. The difference lies in the properties of the material and its thickness. There are three types of linoleum:

- Domestic - It is the most inexpensive and thin material used most often in residential premises. It is easy to clean, flexible and moisture resistant. It is made on a foamed base with a carrier layer of fiberglass, on which a layer of chemical foam is applied on both sides.

- Commercial - the most durable and thick, not afraid of all sorts of chemical and mechanical effects. It is also called industrial, but it is also suitable for residential premises. By combining the multi-colored parts of this linoleum, when laying it, you can select special zones or simply create your own pattern.

- Semi-commercial - The average option between domestic and commercial.

It also happens cork, liquid and 3D-linoleum. There are species that have antistatic or fireproofing properties, as well as a warmed version. It already has in its basis a material that serves as a substrate of fiber or jute on a natural base or from synthetic polyester.

Kinds

When building a room from scratch, the choice of flooring is done in advance. In a private house, the floor is usually warm, smooth and reliable, so any type of linoleum is chosen, and the substrate is not needed here. Also, it is not necessary if they want to lay linoleum on top of an existing one, if the latter is in good condition. But when the floor is repairable or the task is sound and heat insulation, the substrate will help to solve these problems. As a rule, this is required in post-war houses with wooden floors, houses of hut type, "Khrushchev" and private buildings.

For sound insulation

For sound insulation, you can choose a cork backing. This is perhaps the most versatile option, albeit an expensive one. Environmentally friendly, pressed from the bark of the tree substrate gives softness, but under the influence of mechanical loads deforms, leaving dents. Therefore, it should be more dense. You can put it in a room where they do not use bulky and heavy furniture. The option with a combined substrate will also reduce the amount of penetrated noise. Its composition includes wool, flax and jute.It is quite dense and tough for such a coating as linoleum, and therefore it is very well suited for it.

A foam version can also be used, it is less environmentally friendly, but much cheaper than the others. It is produced from polymers of porous nature, the basis of which is an isolon, or penoizol. In addition, a thicker version of the substrate under the soft linoleum will not work, it will break. With frequent walking his pores stick together and over time, “paths” are obtained in those places where they most often attack linoleum. To get rid of these troubles, a thin plywood layer or hardboard is nailed to the top of the substrate.

Rolled substrates are fastened between themselves with the help of adhesive tape or mounting stapler.

For insulation

In addition to sound insulation, floor insulation is often required. It should be noted that the wooden floor itself is warm. But there are objects located above the arch of the building, on the ground floor, with a raw basement or just in the joints of exterior slabs or brickwork there are fistulas.

In these cases, there is always a draft under the floor. In addition to the cork and composite substrate, which are also heat insulators,use a material made from flax fibers, which are rolled on special machines under the influence of high temperatures. This option protects the surface from drafts and also provides ventilation between the base of the floor and linoleum, which prevents the accumulation of moisture inside.

The substrate of jute does not get wet, but absorbs moisture into itself, gradually getting rid of it. These options are impregnated with fire retardant, which does not allow the tree to rot and protects against fungus. The foam material warms the floor well and protects the space from drafts. But you need to consider that over time, it wears out. In addition, he does not let moisture. In combination with waterproof linoleum, accidental water ingress into the joint does not bode well.

Styling details

When laying linoleum on a wooden floor, the most attention should be paid to the quality of the base. We must strive to create a perfectly flat surface of the surface. The end result depends on it. Sharp drops of more than two to three millimeters, peeling paint, gaps between boards, heads of nails or screws, cracked knots will be noticeable under thin linoleum.Moreover, in these places linoleum is wiped faster, and with frequent load it breaks with time. To get rid of the flaws, the floor must be leveled.

For this purpose, special polymer blends with reinforcing fiber are used as the substrate. Apply this method when you need to save more space in the room. The solution can be applied in several layers, previously using a special impregnation before each layer. It is impossible to apply mix on a plaster or cement basis. Due to the properties of the tree, there will be no result change in its density under the influence of external factors. If the floor has minor defects, it is enough to use a foam substrate. This is the fastest, cheapest and easiest method.

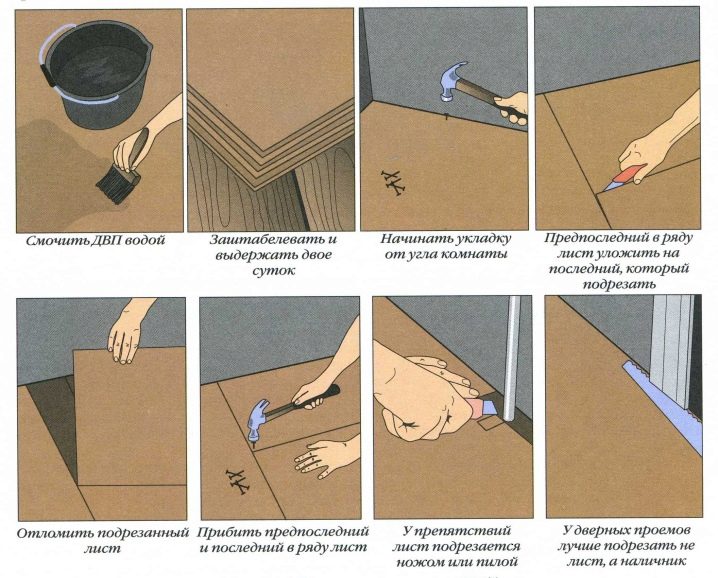

A slightly more labor-intensive and inexpensive way is to nail the sheets of hardboard. It is possible to level the basis with plywood, chipboard or OSB-plates of the third-fourth category. It should be borne in mind that when wet and subsequent drying, particleboard and fiberboard change their shape, which is not restored. Therefore, they are used in dry rooms where water supply is not used.

Floor leveling

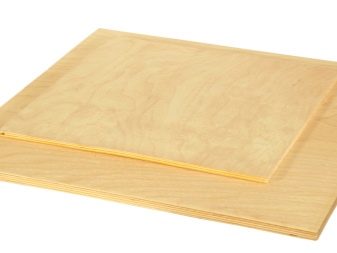

The best option and most often used for this is plywood. It can be glued onto liquid nails, with parquet glue or water based, such as PVA or Bustil. You can nail it or pull with screws. Holes for screws must necessarily prosenkovat drill size caps to drown them. Before plywood, it is advisable to drill plywood with a thin drill of 2-3 millimeters. This is done in order to loosen fasteners if necessary, if lags rise during installation.

Plywood differs in the different composition of resins used in its manufacture. Bacolized plywood of the FSB, BFS, BFV-1 grades is distinguished by high water-repellent properties and a density of 1000 kg / m2. It is used mainly for exterior work, and it is not recommended to make a substrate out of it. Use birch aviation plywood brands BP-A, BP-B, BS-1 is expensive. It is moisture resistant, above average and its density is 500 kg / m2.

But the construction plywood of the FK brand, in which the veneer is glued together with the use of the FKM carbamide resin, made on the basis of FBA melamine resins, is just suitable for leveling the floor.It is environmentally friendly and cheaper than others, has an average moisture resistance. Plywood brand FSF less environmentally friendly. Due to the use of phenolic resin, but it has increased moisture resistance.

There is still additional marking. H - not polished, Ш1 - polished on one side and Ш2 - on both sides. In this case, the choice is a matter of cost savings. The thickness for the selection of plywood is ф of the finishing coating. The best option is 10 mm. The distance between fasteners is 15-30 cm. This prevents the veneer from swelling.

Before installation, it is advisable to dry the plywood indoors in a vertical position for two to three weeks. Cut it on a hard surface to avoid stratification of the veneer. Edges cleaned with sandpaper chipping. During installation, the distance from the wall should be 8-10 mm, and between the plates - 2-4 mm. The seams are puttied with mastic. After drying, they are sanded with sandpaper. Before linoleum flooring, plywood is coated with hot linseed or wood primer. To increase the strength, several layers of acrylic lacquer can be applied. This is desirable but not required. Appearance in this case is hidden, so it is cheaper to buy second-rate or third-grade plywood.

Preparation for the flooring

When the floor is badly worn, it needs to be repaired.Decayed, having a mold or fungus boards dismantled. Such places should be burned with a blowtorch or treated with an antifungal solution, depending on the size of the damage. Loose boards are nailed to the logs. Large gaps are clogged with wooden strips, small ones are puttied. The curved boards are aligned with a plane. Minor flaws cycle and polish. The old paint is heated by a building dryer and dismantled with a spatula. It is impossible to use a grinder as the paint melts and the skin instantly clogs.

If these manipulations represent a very large amount of work or there is a significant difference in the level of the floor, and the foundation is solid and allows height, you can make a new skeleton of the rails at least 2/4 cm. To do this, find the highest point and fasten the initial rail directly to it. And further down the level, using linings or wedges, we mount the crate of 40/40 cm. You can nail it. It is easier to use screws, but they are fragile. It is better to use dowel-bolts. Naturally, the caps are flush flush with the sheathing. If the floor is completely bad - it will have to be restarted.

How to wait a substrate for linoleum on a wooden floor, see the video below.