Mastic for linoleum

Linoleum was and remains the most popular flooring. Despite the fact that the cost of good linoleum can exceed the cost of tile, it is still in demand because of a simpler method of installation and ease of maintenance. The service life of this type of coating is not lower than that of laminate, and there are much more ways to eliminate minor defects during operation. In addition, a large amount of products for proper styling (glue, mastic) and many care products that restore the original appearance are now available.

Features repair coating

Each coating during the operation does not get better, and linoleum - is no exception. It often appears dents, bubbles or bumps, it happens that holes or burns are formed.

You can eliminate these shortcomings yourself., using some tools designed specifically for this purpose. However, it is worthwhile to say that, recommending to level the floor before laying PVC coating and apply adhesive mastic over its entire surface, the manufacturer does not want to complicate your life. With proper installation of all these standard damage (punctures, swelling and waves) can be avoided.

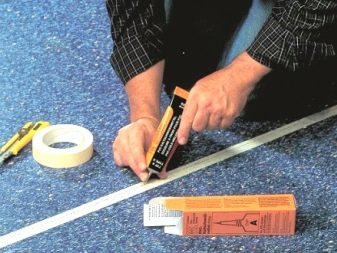

To restore the old canvas, seal the hole and patch the torn linoleum, it is enough to use cold welding. These include special types of glue, which do not glue, but fuse the ends of the gap. There are several types of welding: for baseless linoleum butt joint (class A), for felt (class T) and for repairing large gusts with a gap of 4 mm (class C).

Before gluing a breakthrough, you need to stick paper tape on the joint to avoid damage to the top layer of linoleum. Then an incision is made at the place of rupture and welding is introduced with the help of a nozzle with a thin spout. Scotch fails 30 minutes after repair at an acute angle.

To smooth out the waves and creases, you will need a building dryer.With its help it is necessary to heat the place of swelling until the linoleum is soft. After that, the coating is pressed to the floor with a load for a day. If you don’t have a construction hair dryer, you can take an iron and thick paper through which the base is heated. To remove dents and creases in this way is more difficult, especially heavily sagging places. But if it is good to heat the surface and then roll it with a metal disc, like a rolling pin, then there is a 70% chance of successfully repairing the coating.

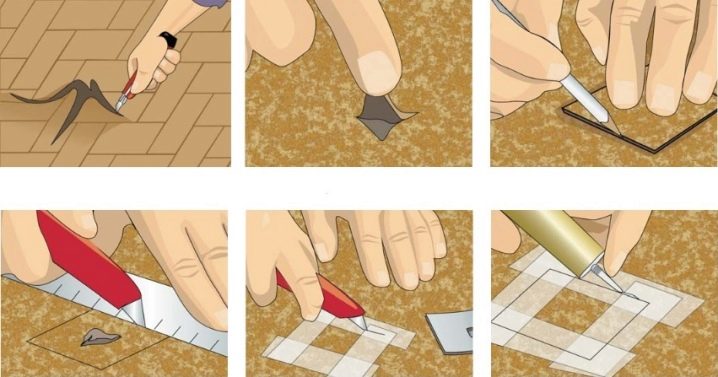

Bubbles and bumps after installation are eliminated rather quickly: With a construction knife on the bubble, an incision is made crosswise, a mastic or glue is squeezed into it, and the place of the incision is pressed against the floor for a day with a load.

To repair the burn, you will need to make in its place a patch of the same linoleum, which is cut out of the remnants. The patch is glued to the mastic, the joints are processed by cold welding, the patch is placed under the load for a day.

Corrosive stains are removed by special means. Do not use abrasives (including sandpaper), bituminous and oily products (gasoline, thinner, toluene).They remove the upper protective layer, after which it will be impossible to clean the contaminated linoleum.

Small repairs do-it-yourself is available to everyone, but it is desirable to prevent defects by proper installation.

Types of mixtures for recovery

Mastic for gluing is sold already in finished form or made independently. Each type of linoleum requires its own type of mastic, which is easy to make at home. To glue PVC a coating or linoleum on an alkyd basis, homemade casein glue is used, consisting of casein, drying oil, water, lime. If you have a wooden or metal base, then for alkyd linoleum it is better to use lacquer-chalk mastic (consisting of resin varnish and chalk). On concrete, you can glue casein-cement composition.

Industrial mastics based on natural cementitious components are also used for the concrete floor and for grouting. One of the most popular is cold bitumen mastic, which is used for gluing any type of linoleum. Quick-hardening mastic on waterproof binders is lime-bitumen, which has in its composition bitumen, water and asbestos and has full water resistance.

In addition to reliable fixation of the coating to the base, it additionally provides waterproofing, preventing leakage to the neighbors from the bottom in the event of an accident of heating or water pipes.

Mastics with polymers are bitumen-rosin, bitumen-latex and rubber-bitumen("Izol" and "Whiskey"). The first two are used for gluing PVC linoleum to a wooden base or on concrete screeds. Bitumen-latex mastics are very well applied with a conventional trowel, do not stretch for the tool and allow you to create a thin layer of glue on the floor. However, they very quickly set and can be used in an unheated room. Excellent for gluing PVC linoleum to fiberboard, particleboard and concrete.

If you have linoleum on a fabric basis, then the best option is the Biska rubber bitumen mastic, which is absolutely harmless and explosion-proof. One disadvantage is the gradual set of strength - within a month. Therefore, it is desirable in the first week after laying linoleum to refrain from a strong impact on it.

Functions

Mastics for linoleum are of two types: for rubbing the floor (protective function) and for gluing linoleum to the base.

The ideal option is to apply protective mastic to the coating immediately after its installation. But if this is not done, then, if desired, the protective composition can be applied later.

The main functions of protective mastic:

- shine to the coating;

- reduced antistatic effect;

- increased traction (slip prevention);

- protection from scratches, facilitating washing and preventing ingress of corrosive dirt into the deeper layers of the protective coating;

- protection against burnout, increased resistance to UV rays.

All modern mastics have polymeric additives in their composition, which allows to preserve the elasticity of the coating for a long time, and without creating craquelure (cracks) on its surface.

Drawing

Application of mastic care at home is not difficult. However, before covering the linoleum with a protective compound, it is necessary to carry out its full cleaning. Cleaning is done by means of the same brand as the mastic. As a rule, the manufacturer produces a whole line for the care of PVC coating or natural linoleum. An integrated approach guarantees the protection and preservation of the presentation for decades.

First, the most persistent household contaminants are removed from the floor — grease stains, black stripes from shoes, stubborn paint stains. To do this, use the cleaning composition in a fairly high concentration - about 3 caps of cleaning agent for 2 liters of water. The product is applied directly to the stains and left for at least 15 minutes. After that, the dirt is removed with a sponge for dishes.

Then the product is diluted in a ratio of 1 cap to 2 liters of water and the entire surface of the floor is washed with it. It does not use a mop, it is best to do it manually with a microfiber cloth, helping yourself in hard to reach places with a sponge with a soft abrasive.

The final stage of surface preparation is flushing it from detergent with plain water. Change of water is 3 times. First, a rag is washed with running water in the running water, it passes the entire floor for the first time. Then the second change of water and rag, after the third change of water (rag can be left the same). After washing the floor should be left to dry completely. Make sure that no one passes on it and leaves no traces.

If the floor was dried on a draft or before applying a polish, it does not completely dry, then polymer delamination is possible after a couple of weeks.

No matter what kind of mastic you have: matte or glossy, it is applied only with a lint free cloth or linen. A small amount is rubbed into the linoleum only in a circular motion with pressure, avoiding the accumulation of funds at the edges of the circle (white stripes). After a 30-minute break, a second layer of mastic is applied in the same way and left for 40 minutes until completely dry. In no case can not walk on the newly treated coating.

Apply mastic on the floor at home is recommended once every two months, but in the offices it is necessary to carry out a full restoration every six months, sometimes every 4 months.

This simple instruction will help you quickly and accurately restore any linoleum without the help of specialists.

Recommendations for selection

There is one firm rule - the purchase of mastic is done only after the purchase of linoleum. In this case, you definitely need to ask the seller what kind of linoleum you buy (PVC, alkyd, natural) and on what basis. These data and another type of base on which the coating spreads are the basis for the choice of adhesive composition.

For foam, baseless and linoleum on a felt basis, there are different means. It is worth remembering that the universal remedy (for all types of coatings: carpet, linoleum, tile, etc.) is suitable only for PVC linoleum on a foamed base and only for concrete or fiberboard / particleboard.

Consider the difference between dispersion formulations and directly mastic. Dispersion glue is always water based (bustilat, acrylate, PVA, Gumilax), the mastic always contains admixtures of adhesives: gasoline, solvent, bitumen. Mastic, in contrast to the dispersion composition, provides almost 100% waterproofing.

Natural linoleum and marmoleum is glued only on dispersion glue. Mastic is better to choose if the base is very wet or you lay a conductive linoleum. Reviews of masters say that for the house it is enough busilate or acrylate.

When laying and caring for linoleum, the best option would be to purchase care products of the same brand as linoleum itself. Glue and care tested specifically with this foundation, they are guaranteed not to spoil the flooring.

Case Studies

Forbo 897 - anti-slip care mastic that protects the coating from the appearance of black stripes. Scope of application - rooms with high traffic (offices, hospitals, schools) and sports halls. Forbo 898 "Longlife Basisschutz" in a glossy and matte version incorporates metal polyacrylate, which allows its use on all types of linoleum (PVC, alkyd and natural, including marmoleum). It is deeply absorbed into the base, pushes the dirt out, resistant to abrasion.

Mastic for bonding Forbo 628 Eurostar Rapid fiber-reinforced, perfectly applied to the floor, not squeezed out of the edges of linoleum. Suitable for laying underfloor heating, not under the influence of roller chairs. Setting time - 24 hours.

Tarkett Company It is not engaged in the production of mastics, however, it offers excellent cold welding of all three types for gluing linoleum joints and its household repairs. Welding is performed in Belgium and is used only for interior work. Type A - for linoleum PVC (baseless and foamed), type T - for polyester backing.

HomaKoll 248 - dispersion adhesive based on PVA, suitable for PVC coating. Opinions on his account were divided exactly in half: 50% of masters categorically do not recommend gluing to him, because the coating is inflated with waves, 50% have no complaints,it is said that before applying the surface of the floor, it is desirable to double primed. Unanimously, the dismantling of the cover is easy. At the same time, many note that the bank indicated an incorrect consumption, and for semi-commercial linoleum, despite the assurances of the manufacturer, the glue does not fit perfectly.

For how to cold weld linoleum, see this video.