What should be the glue for linoleum?

Linoleum is a popular material for flooring. It is used in the arrangement and repair of floors both in industrial enterprises and in everyday life. One of the problems with this product is that sheet sizes are limited. To connect them well, use special glue. These substances are of several types, as they differ in quality and method of application.

What is the name of?

Glue for linoleum can be used to solve several problems:

- gluing joints in order to obtain a surface without chipping;

- gluing the sheet directly to the subfloor.

You can glue these substances with various adhesives. The most popular mixtures for working with joints are the following brands:

- Werner Muller type A. Cold welding is intended for bonding household and industrial linoleum.

- Homakoll S 401. Another type of blends based on polyvinyl chloride. It can glue not only linoleum of a similar composition, but also all types of PVC plates.

As for adhesive compositions for floors, here you can highlight the following names:

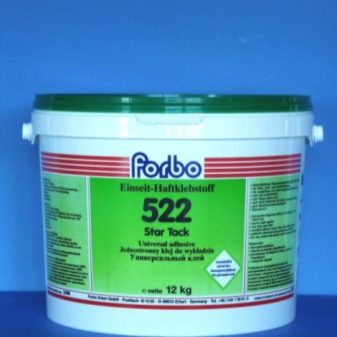

- Forbo Erfurt 523. Glue has antistatic properties that allows you to lay with it conductive and vinyl coatings, as well as for semi-commercial use.

- Homakoll 208. Universal substance that is intended for gluing linoleum on several types of surfaces.

There are many other brands of glue, which differ in names and technical properties.

Special features

Glue for linoleum is a great opportunity to get not only a smooth and comfortable, but also a durable surface, put with your own hands, which is much more difficult to damage. Compounds for bonding joints are reagents that dissolve linoleum during a chemical reaction. After drying, a strong bond is formed. A feature of cold welding is that it is used only for PVC-based linoleum. It is impossible to glue other modifications, which limits the environment of use. One of the advantages of the reaction adhesive is its plasticity and resistance to moisture.This is due to the fact that after drying the joint in composition is practically no different from the structure of linoleum. But such solutions emit harmful substances into the external environment, therefore they are rarely used in domestic premises.

As for the glue used for gluing the fabric itself, it forms a strong bond between the subfloor and the material. Similar solutions are applied directly to the floor before laying linoleum. Technical characteristics of the material allow to work with different types of surfaces. But some of the varieties can withstand moisture, while others are not. All these features depend on the specific brand of the mixture. They are important to consider before you purchase a certain material. neither, felt, etc.

Adhesives of this type have several universal features:

- They are completely harmless to humans, which allows them to be used in almost any room.

- The composition after application does not emit virtually any odors.

- High elasticity. This allows the linoleum to respond qualitatively to high loads, minimizing the risk of damage or displacement.

- Versatility.Adhesives of this class are used not only for PVC coatings, but also products made of cloth.

But these substances withstand frost relatively poorly and after such exposure lose their original qualities.

Composition and types

The variety and structure of linoleum can be different, which does not allow to use for its installation the same types of adhesive solutions. Conventionally, these substances are divided into 2 main subspecies:

- Dispersive. These solutions are necessarily in their composition suggest the presence of water, acrylic and other additives. Substances do not differ in high frost resistance, but manufacturers constantly improve these indicators.

- Reactionary. This mixture is an adhesive that, when it comes to PVC, the coating reacts with it. As a result of such exposure, a liquid component is formed. After solidification, it again becomes as hard as the rest of the linoleum surface. This mixture consists of tetrahydrofuran (up to 80%), PVC and special plasticizers. The material is completely waterproof, which allows it to be used in wet areas.

Dispersion glue can be divided into 3 main types:

- Bustilat. This solution is versatile and can glue linoleums, which are complemented by a felt base. This substance consists of chalk, latex and carboxymethylcellulose.

- Acrylate adhesive. Water-dispersion solutions have a very high viscosity, which allows to obtain a strong bond of the connected components. This product consists of thermoplastic resins. Glue is suitable for rooms with different levels of load. The solution perfectly captures not only single-component materials, but also is suitable for felt types of linoleum, frost-resistant.

- Gumilak. The glue is also practically universal, since it can be used to combine both substances on a natural basis and synthetic products. It is made of latex and rubber, which are completely harmless to the human body.

Some modifications of the considered varieties of glue can be used for laying conductive elements (arrangement of underfloor heating, etc.).

The reaction glue, or liquid nails, resembles a paste and is produced tubes. These substances are also divided into several types:

- Type A. The mixture has a liquid consistency, which allows you to fill high-quality large gap (up to 2-3 cm). The polymer filler thus forms a viscous material, which is almost impossible to distinguish from the colors of linoleum. Working with this solution is quite simple, so it is often used in everyday life.

- Type C. The material is suitable for small cracks or joints, the distance between which does not exceed 0.5 cm. It is much thicker than the previous type.

- Type T. This type is used for linoleum, in which there is a felt base. It is relatively rare, as many prefer the previous species.

Which one is better to glue?

The choice of glue for linoleum is a complex task that requires the evaluation of several parameters:

- Type of surface to be joined. If it is homogeneous linoleum and you need to seal the joints between the sheets, then apply the reaction solution (cold welding). When it is necessary to glue it to the floor, then preference is given to dispersion varieties that are suitable for certain substances.

- Linoleum type. Today there are many varieties of such products. It can be either based on rubber or polyurethane.Gummilak-based solutions are suitable for foamed linoleum, whereas for commercial and semi-commercial varieties, glue should be selected depending on their structural features.

- terms of Use. Many mixtures do not withstand significant temperature differences. If you are planning to lay electric heating under the laminate on a sticky basis, then you should definitely equip the antistatic layer. Here you can use only special solutions that extinguish similar phenomena.

Manufacturers Overview

A variety of adhesive compositions for working with linoleum today is very large. They are produced by a lot of companies, among which there are several brands:

- Werner Muller. The company specializes in the production of both dispersion and reaction mixtures. The latter are distinguished by high-quality compound and durability. One tube of reactionary glue is enough for 10 meters of junction.

- Linocol. The company produces substances that are great for heterogeneous varieties of linoleum, which is based on foamed polyvinyl chloride.

- Thomsit k. Glue designed for sealing cracks and seams.The products are reliable and durable.

- Homakoll. This manufacturer specializes in linoleum sticking to the floor. The line is rather wide and includes several universal products that can be used for heterogeneous materials on various bases (jute, felt, etc.).

- Forbo erfurt. Another manufacturer of dispersion formulations. He manufactures products for various occasions. There are both quick-drying solutions and mixtures for all types of linoleum.

How to choose?

The selection algorithm for glue for linoleum also depends on several factors. For formulations that are intended to anchor sheets to the floor, several characteristics should be evaluated:

- Surface type. The best option for concrete and cement coatings are water-dispersion solutions. They are not afraid of moisture, which does not require the arrangement of a protective substrate. If you plan to lay linoleum on a ceramic or marble tile, then reaction adhesives can be used as a fixative.

- Location environment. When you place linoleum in a living room, then an acrylic composition will suit you.It is completely harmless and does not emit any harmful substances. Please note that there are universal compounds that can work with different materials and surfaces (concrete, chipboard).

- Linoleum type. Practically all the solutions are intended for PVC products, which can be supplemented with different layers. But at the same time, each modification of the mixture has the appropriate recommendations, the observance of which will lead to a more reliable consolidation.

How to use?

Adhesives for such substances are available, and working with them does not require special skills. Each glue manufacturer indicates on the package the approximate consumption of this substance. It is possible to calculate the quantity, knowing that dispersion compositions approximately need 200-600 g per each square meter. Reaction mixtures will go only 300-400 g per square meter. But it all depends on the specific type of foundation. To find out how much glue you need, you should multiply the area that linoleum will occupy by its consumption indicated on the package. Note that the reaction compositions for the joints are calculated in linear meters of the seam.

Today, almost all types of such solutions are sold ready to use.

This is especially true for reaction modifications that are simply applied to the joint or surface from a tube or other container.

As for dispersion formulations, then before using them, you need to prepare them, simply by mixing them, and then apply them on a clean surface with a notched trowel.

Dries glue in different ways. Time depends on the type of composition, its quantity and temperature in the room. For example, the reaction solutions freeze after a few hours, while water-dispersion varieties can dry for several days.

Learn more about how to choose glue for linoleum, you will learn from the following video.