Can I put linoleum on linoleum?

It is no secret that the neat appearance of the floor covering and its harmonious combination with the interior is an important component of a successful design and cozy atmosphere in the house. Wanting to renew their deadline or boring linoleum with the least expenditure of finance, time and labor, apartment owners can make a hasty decision about laying a new coating directly on the old one. However, in some cases, this is absolutely not worth doing.

Why you can or can not put the products on each other?

The first thing to focus on is the degree of novelty of the original linoleum. If the coating is more than fifteen years old, it is deliberately subject to disassembly due to accumulated dust, particles of dilapidated fabric base and dirt (especially between the seams). Laying fresh linoleum on such a surface seems extremely unhygienic and devoid of meaning.In addition, if there is a suspicion that the condition of the floors has deteriorated over time, it will be advisable to make a new screed before installing the fresh coating.

Another serious obstacle to putting a new linoleum without dismantling the old, is the latter has the following defects:

- "Waves";

- potholes;

- torn pieces;

- breaks;

- noticeable cracks.

Such imperfections of the original coating will sooner or later appear on the new linoleum, since, subsiding and crushing during operation, it will simply repeat their shape.

It is also extremely important to trace whether the surface of the old linoleum is not affected by mold. Unfortunately, this problem is characteristic of many old coatings. The reason is that the polymer protective layer of linoleum does not allow air and evaporating moisture, resulting in favorable conditions for the emergence and growth of mold colonies. In addition to its unpleasant odor and repulsive appearance, the mold carries two serious dangers. First, inhalation of mold spores can cause problems with the respiratory and digestive systems, as well as allergic reactions.

In addition, having the property of unceasing growth, the mold can eventually penetrate into the thickness of the subfloor, causing the boards to rot or crack the concrete screed. Despite the presence of many folk remedies to combat this type of linoleum defect, the only right decision would be to dismantle the original coating, even if it is perfectly even and the service life has not yet come to an end.

Another obstacle to laying a new material on the old one is the uneven surface of the floor itself. Often, the “waves” and bulges of the original linoleum are due to the fact that the coating simply repeats the relief on which it was laid, so if the floor height drops to more than 2 mm, the old coating is to be eliminated and the floor to a new screed.

When the area of the room over 10 m will be useful to check how firmly fixed the old linoleum relative to the floor. In case the original coating was not glued, it should be dismantled., because even being firmly fixed to the old, the new linoleum will not fit snugly to the floor itself and will easily be subject to the formation of irregularities and "waves" when it dries after installation.

In the absence of these contraindications to lay a new linoleum on the old coating, its dismantling is optional.

Moreover, the source material will provide excellent noise insulation, will make the floor softer and warmer, and the time and money spent on repairs will be significantly reduced, since you will not have to purchase an expensive substrate and carry out long-term preparatory work.

Eliminate defects on the old coating

Before you start laying new linoleum on the old surface, you must carefully examine it for any microdamages and eliminate all visible flaws. Possible defects include the following:

- dents from furniture legs;

- minor cracks and cuts;

- bubbles;

- bulge.

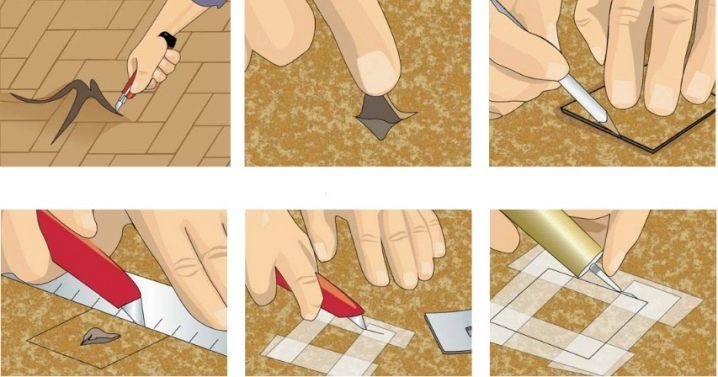

A universal way to eliminate most defects is install patches (or patches), made from a piece of linoleum, unused. The ideal option would be to use residues of the same linoleum, which is being repaired. If there are none, you should choose the linoleum corresponding to the thickness (measured using calipers) and the structure of the original (special attention is paid to the substrate material).Often in the construction markets it is possible to choose the required coverage from the remains of linoleum offered for sale.

In order to make a neat patch, you need to cut a damaged piece of linoleum (preferably oval or round, but square is also acceptable), then cut a patch a couple of centimeters more from the removed piece with the defect. Having applied a patch in its place, it is necessary to cut its outlines with a sharp stationery knife along with the original coating. After that, it remains to remove the trimming of new and old materials and glue the patch with mastic, smearing the joints with cold welding for linoleum.

In order to align the crack, you can also use the method patches (with plaster leveling deepening and subsequent grinding) or simply glue the defect from the inside. To do this, one cross section must be made on each side of the crack, so that the letter “H” will be obtained. Then you should bend the edges of the crack and apply mastic on the substrate and the floor. In order for it to properly grab, you must firmly press the glued crack to the floor and leave it for some time under the load. Microcracks, like seams, can be simply filled with silicone sealant.

If bubbles are formed on the old coating, before applying the already familiar patchwork method, you can try to introduce glue into the inside with a syringe and also hold the damaged area under the weight of the load.

Conditions of laying new linoleum on the old

Observing the rules of installation of new linoleum on the old coating, it will turn out to lay it so that it will serve you for many years:

- It is important to remember that laying a new coating on uneven linoleum is fraught with the fact that it will soon repeat all the flaws of the old one, and therefore, before installing fresh material, you must make sure that the original defects have been corrected.

- The next condition is the purity of the old linoleum. It should be thoroughly cleaned from dust and dirt, otherwise the organic matter in its composition will spread an unpleasant smell after the installation of new linoleum.

- The room in which the repair will be made must be completely freed from the furniture for a few days: the new coating will take at least a day to rest in bed and smooth out. You should also remove the baseboards and connecting plates, if any.

- You can cut the linoleum directly in the store, it is desirable that it was a solid piece, so you do not have to spend time joining the seams.Currently, the industry produces rolls up to 5 m wide, which is enough for the area of the rooms of the vast majority of apartments. If it is impossible to do without seams, the number of joints should be reduced to a minimum.

- When cutting the material should be borne in mind that between the wall and the extreme strip should remain a small gap. Such a reserve is made so that the linoleum does not go "waves" during shrinkage after gluing to the original surface, and lay down freely and firmly pressed against the original coating.

- After cutting the new linoleum, you must leave it for a few days in the room where the installation will take place. During this time, the product will lie down and take the necessary position.

To work you need the following:

- gloves

- rubber roller (for smoothing irregularities after fixation)

- sharp stationery knife

- duct tape

- glue

What to stick?

Despite the fact that some experts allow the laying of linoleum in small rooms without using any fixing material, the fact remains: the uncovered coverage is much more vulnerable during operation.Experienced craftsmen warn that the lack of adhesive base under linoleum reduces its service life by almost half. The choice of glue depends on the characteristics of the base of linoleum, the state of the original surface, as well as the specific task of the workflow.

A water based dispersion adhesive is used to fix the main surface area. Among its advantages are the absence of a pronounced odor, non-toxicity and high elasticity, which is important for shrinking linoleum. In addition, this adhesive has high adhesion (adhesion with the surface) and is easily applied to the material.

There are several types of dispersion glue:

- Acrylic;

- Bituminous mastic;

- Bustilat;

- Gumilaks;

- Conductive.

Acrylate will be an ideal solution for gluing linoleum, designed for high loads, mastic is good for coatings on the fabric basis. Bustilat is used for thick coatings on a warmed basis (for example, felt). Gumilaks is designed for the installation of natural linoleum, and the use of conductive glue is suitable for rooms with a large number of electrical engineering.

When laying new linoleum on glue, it is necessary first of all to bend over the entire length of the wall half of the cloth and apply glue to it with a notched trowel, the layer thickness should be 0.5–0.6 mm. Next, the missed part must be pressed to the floor and using a rubber roller and smooth out all the bubbles (if you do not pay attention to this, the floor will noticeably slip and warp when walking). After this, it is necessary to do the same manipulations with the second half of the covering and install the plinth.

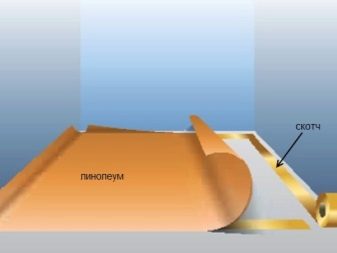

If the fixer is selected double sided tape, the principle of work is very similar. The first side of the cloth is folded down and fixed with adhesive tape, then the material is stretched to the opposite wall, and the excess material is removed with a sharply sharpened clerical knife. After that, the new linoleum is fixed with scotch tape around the perimeter. At the final stage are installed skirting.

If there are joints, they should be correlated and fixed first. This can be done using double-sided tape or thick paper, missed with PVA. After the two pieces of cloth have been fitted tightly and glued together without gaps, to speed up the glue drying, you can shoot the seam with a natural cloth and heat it with an iron turned on to maximum.

Another highly effective method of mounting joints is use of editorial glue (cold welding). When choosing cold welding (in fact, it is a liquid glue that dissolves linoleum and, while freezing, forms a monolith), it is necessary to take into account that it is of two types. Type A welding is ideal for millimeter gaps, for more thorough (up to 4 mm) type C welding is used. When hit in the slot between the pieces, the welding solidifies and becomes a monolith, ensures the reliability of the joint for many years.

With regard to the use of hot welding at home, this method is undesirable. For its competent and safe use, you need experience and specific knowledge of a professional.

If fitting the edges is difficult, because the floor spreads overlapping for one reason or another, you should cut out the place where the pieces fit together, and after removing the pieces, you get the perfect joint. However, it should be noted that this method of docking is possible only when installing a monochromatic coating.

Another important aspect in working with seams is their proper location relative to the source of natural light.The joint should be perpendicular to the window, otherwise it will be visible in daylight.

After installation of the joints, gluing of the total surface, removal of excess and smoothing of the coating, it is necessary to allow it to lie down and fully finish in 2-3 days. After that, you can do the installation of baseboards. Traditionally, PVC products are best suited for linoleum, but there are no obstacles to choosing natural or veneered. Begin to put the baseboard with a corner with screws.

How to choose the product?

When choosing a new coating, it makes sense to take into account the following key characteristics:

- structure;

- purpose and classiness;

- composition.

According to its structure, linoleum is divided into heterogeneous and homogeneous. The first type consists of several layers (2-7), the uppermost of which is a transparent layer and is responsible for wear resistance. Next comes a decorative layer containing the pattern or design of the product itself. The last component of a heterogeneous coating is from one to several layers, which increase the tensile strength and give insulation to the material.

In addition to a number of obvious advantages, such linoleum will be an excellent solution in the situation when it was not possible to achieve a perfectly flat surface of the source material even after removing all imperfections.

However, it is worth considering that the cost of heterogeneous coverage is significantly higher than that of its counterpart.

As for homogeneous linoleum, usually consisting of only one layer, it also has its advantages. Firstly, the price of such a coating is lower, and secondly, its design remains unchanged throughout the entire period of use, since the pattern lines go through the entire thickness of the material. In addition, the indisputable advantage of homogeneous linoleum is the ability to update it after a long service life by grinding.

Before choosing single-layer linoleum, you should make sure that the surface of the original coating is really perfectly flat. Otherwise, the thin surface of the new material with time will repeat the relief of the old.

The next characteristic of linoleum is its classiness, which stands out for each of the following three groups:

- household (non-commercial);

- semi-commercial;

- commercial

For household linoleum, designed specifically for laying in residential areas, there are three classes (21, 22, 23), each of which represents the degree of permissible load on the floor. Thus, the product, marked with the number 21, is adapted for a low level of load on it; accordingly, its installation will be appropriate in rooms with low traffic (for example, a bedroom or a storeroom). The figure 22 means that the products are designed for medium load, and therefore, can be laid in the dining room, living room or office. For the kitchen and hallway it would be wise to choose products with maximum wear resistance: class 23 linoleum would be the right solution for the kitchen or corridor.

As for semi-commercial linoleum (it also has its own class system), its qualitative differences from the household counterpart are minimal, but the cost is significantly higher. If the financial issue is not a big deal, it would be wise to choose a commercial type of coating right away, such linoleum will last at least 10 years without the appearance of creases, dents and other unpleasant defects.

According to the material linoleum happens the following:

- natural;

- polyvinyl chloride;

- colloxin;

- glyphthalic;

- rubber.

The highest demand in the modern market enjoy natural and polyvinyl chloride. Natural linoleum incorporates exclusively natural components: pitch, the crushed oak bark, limestone, linseed oil and natural dyes. It is made both with a basis (a jute cloth), and without.

Among the advantages of a natural coating is its high resistance to fading, acids, fats, as well as environmental friendliness, safety and preservation of the original color throughout the entire life cycle.

Polyvinyl linoleum is made from polyvinyl chloride with the addition of plasticizers and fillers, such as limestone powder and pigments. In terms of its structure, it can be both homo-and heterogeneous, the base can be both tissue (gives softness to the floor) and foam (it has improved moisture resistance).

The fact that you can put a new linoleum on top of the old, you will learn from the following video.