Which glue is better to use for PVC tiles?

PVC tiles today have become a very popular finishing material. They have high strength even in comparison with linoleum, and because of the simple principle of laying during the work there will be no problems.

Material advantages

This finishing material has earned the trust for several reasons. Here are some of them:

- Moisture resistance. This aspect can guarantee a minimal risk of wrinkling and swelling of the surface, after a while.

- Strength and resistance to wear. This material is characterized by low susceptibility to mechanical stress. The use of abrasives will not harm either.

- The variety of colors and textures. This will help to make the interior unique and inimitable.

- Easy installation. No need to be a professional finisher to cope with the task. On top of that, styling is possible in various ways: the combination of color, shape, etc.

- The possibility of repair work. In case of damage to any part of the flooring, just need to get the defective area and install a new tile. This feature is a great advantage of PVC tiles in contrast to linoleum. Linoleum can not be partially replaced and will have to remove the entire coating.

- The tile from vinyl successfully lays down in rooms with a small area, and also in places where it is necessary to cut a lot of fragments. This is done with the help of an ordinary painting knife.

The only question that remains is what kind of glue to use when laying such tiles. The right glue will guarantee the long life of the floor covering.

What needs to be considered when choosing?

First of all, it is very important to take into account the specifics and conditions of the room in which the tile will be laid, namely:

- The level of humidity.

- Too high or low room temperature due to various factors.

- The presence of open sources of fire.

- The probability of a high load on the floor (warehouses, etc.).

- Installation of floor heating system (high level of thermal conductivity of the material is required).

- Exposure to adverse environmental factors.

Due to the fact that some materials interact poorly with adhesion, an important factor is also the appearance of the original surface. Today, glue for PVC tiles is being produced, which it seems possible to use for many types of initial surfaces: cement, wood, plywood, old PVC coating.

The main parameters of the adhesive composition

Mixtures for the preparation of glue must meet the following requirements:

- Ease of application.

- The duration of the work with the mixture.

- The level of strength of the seams.

- Sufficient thermal conductivity.

- Compliance with fire safety requirements.

- Resistance to high and low temperatures.

- Moisture resistance.

- Degree of resistance to wear.

An important condition for high-quality mounting of tiles is the cleanest surface for laying. In view of this, the floor must be primed. Before starting work, try to calculate the necessary amount of glue as correctly as possible.

Special formulations for bonding are of two types:

- glue;

- fixation.

The second kind differs from glue in ability not to dry up to hardness. After drying, a sticky base is formed, similar in properties to scotch tape. The convenience of this method is that the attached coating can be glued and peeled off several times. Everything is done quite easily, even after a few years.

The only nuance is the impossibility of offset coating. You can peel off the planted surface by pulling the tile up, holding onto its edge.

Subtleties when working with quartz vinyl tiles

The surface on which the tile will be laid should be flat, free from any type of contamination and thoroughly dried. The peculiarity of vinyl tiles is their ability to not pass moisture. In view of this, if some moisture remains under the tile, it will gradually accumulate, which will lead to the destruction of the adhesive and the coating itself.

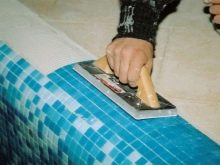

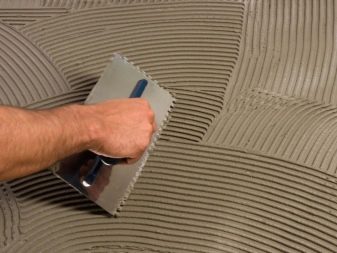

After checking the absence of all the defects of the original surface, you can proceed directly to the laying of the tile coating. In progress care must be taken that air does not get under the surface. Also, it should not be laid tightly against the wall, it is recommended to leave a small gap. With this type of repair work, the best option would be to choose a notched trowel with a set of interchangeable blades. This will provide an economical glue consumption.

After a complete laying of the tile covering, it is necessary to walk on it with a weighty rubber roller or to wipe it with a corkboard.

Acrylic adhesive

For PVC tiles, acrylic based adhesives are mainly used. Acrylic adhesive composition is dispersion and epoxy.

Features and benefits:

- Environmental friendliness. A special chemical compound is not harmful to health.

- High degree of adhesion with various materials.

- Viscosity. The composition does not flow, which makes it possible to combine any materials.

- High level of resistance to mechanical stress.

- The structure allows the use of glue on various surfaces.

- When working with tiles, it is advisable to use glue-suspension. In its composition there are solvents that evaporate and ensure the mixture hardens.

- Latex-based adhesive products are becoming popular due to the non-flammable composition,lack of toxicity and harmful odor.

- Water dispersion glue dries for a long time and is used quite rarely.

- No unpleasant odors.

- High moisture resistance.

- Various applications.

Main characteristics:

- In a short time, seizes the surface, which puts it on a par with ethyl-containing glue.

- It has the color of light beige paste.

- Gluing properties are shown within 10 minutes.

- In the course of drying the plastic strong film forms. After a day, the glue dries out completely, which makes the surface ready for various loads and further work.

- With the help of a roller with cloves, it is easily applied and thereafter no fingerprints from the spatula remain on the film.

During the work does not need to apply special precautions.

Basic requirements when working with acrylic adhesive:

- The air temperature in the room should not be less than 10 degrees.

- Do not apply on wet surface.

- For uniform distribution of the layer, use a notched trowel.

- If in the process of work the glue hit the front side of the tile coating, it should be immediately removed with a soft cloth moistened with alcohol solution.Otherwise, the stain will dry quickly, and it will be much more difficult to remove the defect.

- The original surface should be leveled, pre-dried and cleaned.

How to lay?

Material preparation

Before carrying out work, you should make sure that the selected composition corresponds to the temperature regime of this room. An important point is also acclimatization. Building material one day before use must be placed in a room in which repair work will take place. The adhesive composition is also placed in the same place the day before use.

Applying adhesive composition

Acrylic glue is applied with a notched trowel designed for these works. It is important to evenly distribute the composition over the entire surface. The period of exposure is determined by the type of spatula used, which absorbs the properties of the original surface, air temperature, and the level of moisture in the room.

Cover fixing

PVC tiles begin to be laid after the exposure time, but before the end of the period of working properties of the adhesive. This period is about half an hour after applying the adhesive to the surface. Before sticking tiles it is necessary to apply labels.A tile of rectangular shapes begins to be laid from the corner of the room.

When the first row is ready, a rubber roller passes over the finished surface. This will allow to remove the air from under the tile, as well as better to glue the material. Remove excess glue immediately with a damp cloth. When all vinyl tiles are laid, it is recommended that the roller be repeated over the coating. This will avoid peeling off the edges of the tiles.

The average glue drying time is 24 hours. Time may fluctuate, depending on the room temperature, moisture level and absorbent properties of the base.

Nuances of work

Using in work acrylic glue, it is necessary to know the following:

- Glue on concrete can be easily washed off the skin and working tools with plain water.

- The cost of the adhesive composition is directly dependent on the thickness of the layer and the uniformity of its application. You should also pay attention to the spatula and the structure of the working base.

- Glue produced in packs of 6, 12, 25 kg.

- The composition must be used throughout the year.

For high-quality laying flooring should be a responsible approach to many subtleties. When choosing an adhesive, its main compatibility is with the conditions of the room in which it will be used. Also, close attention should be paid to the shelf life of this finishing material.

How to glue PVC tiles, see the next video.