Cement tile: product features

Many people think that cement tile is the second name for paving stone, a material for finishing pavements. However, this is a misconception.

Cement tiles - handmade products for interior decoration. Such materials are preferred by connoisseurs of elegant interiors, as well as original and non-standard designs.

Production technology

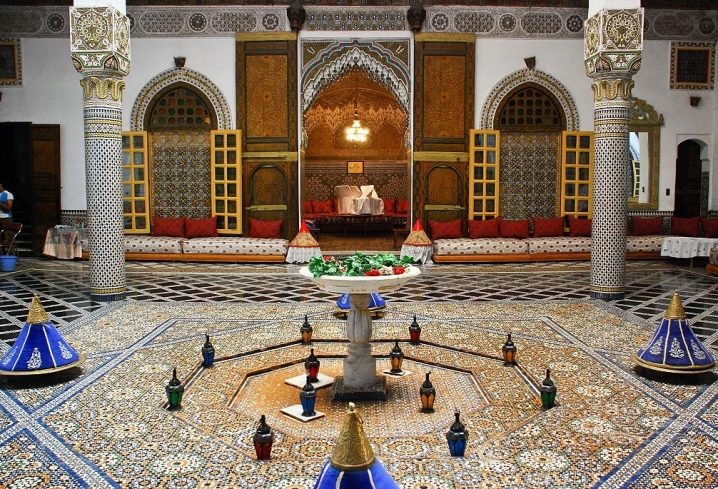

Cement tile - Moroccan "idea". It was invented in the XVIII century. Moroccan craftsmen managed to create a durable and elegant material that can withstand heavy mechanical loads. At that time, palaces and various architectural buildings were finished with cement.

Over time, the manufacturing technology has undergone numerous changes. The following components are used to produce the material:

- cement;

- water;

- quartz sand;

- colored blends for decorative shell.

To create a lining all the components are mixed, after which the material is formed from the resulting mass of the master. Next, the blanks are processed with colored fine-grained aggregate of the pores and smoothed. After these events, the material is “sent” to a specialized drying chamber.

Due to the fact that the products are not fired, the finished tile has excellent strength characteristics.

The material is mainly available in red and brown tones. Some manufacturers "paint" the surface with acrylic paints. Such products look bright and original. However, the cost of such goods will be 20-40% more expensive than normal.

Where is it used?

Cement tile has been widely used for interior and exterior decoration. It is used in the decoration of various premises: living rooms, bedrooms, kitchens and corridors. The material can be put in the bathroom, because it is "not afraid" of high humidity. Cement tile is designed for veneering floor surfaces or walls.

It is able to decorate the home, to diversify the boring interior and to make a contrast to the usual atmosphere.

For exterior finish The material is used for the purpose of facing terraces, facades, garden paths and other house adjoining areas.. Every year, an increasing number of consumers prefer cement tiles, as it is resistant to temperature changes and any weathering.

Material Features

Cement tile has a number of features due to its manual production.

- Heterogeneous color. Material from the same collection can vary by half tone or tone. This is due to the fact that the mixing of paints is done by hand;

- Difference in thickness up to 2 mm. Such deviations are explained by the same "manual" method of production. When laying tiles of different thickness, they are leveled with adhesive;

- Whitish on the surface. This "veil" is created by the interaction of cement with water, as a result of which a thin layer of complex salts is formed on the products.

The above properties are inherent in all tiles (domestic and foreign), made by hand.

Advantages and disadvantages

Designer cement tile is a unique veneer that retains the charm of the medieval years.Colorful, original and elegant products are the best complement to the interior.

In addition to excellent aesthetic qualities, cement tile has the following indisputable advantages.

- High strength (including impact). Products are able to withstand serious power loads. Due to this feature, they can be safely laid on the floor in rooms with intensive traffic.

- Ecological clean. In the manufacture of products used only natural raw materials, so that the finished material does not emit harmful substances during operation.

- Resistance to various external influencessuch as ultraviolet sunlight, excessively low or high temperatures, snow, rain.

- Easy care. Tiles are treated with special compounds, and then polished. As a result, their surface becomes smooth. It is able to "repel" drops of water, dirt.

- Easy installation. Even an unprepared person can lay the lining or decorate the walls with it.

The master “puts the soul” into each cement tile. Such materials reflect the talent of the author and his love for his work.As a result of the handmade work, the products may have uneven color, cement streaks, slightly noticeable stains. However, these are insignificant drawbacks, since the differences in the fragments on the laid panel will not be noticeable.

Styling rules

When installing cement tiles need to comply with a number of conditions.

- Prepare the base. The base must be flat, clean and dry. The presence of dust and small debris on the surface is not allowed.

- Glue is applied to the tile with a spatula with a layer of 5-10 mm. For laying material used tile adhesive composition, the adhesion of which should be more than 1.2 MPa.

- It is necessary to glue the tiles so that the thickness of the joints is 1.5-2 mm. If a tile with a pattern is chosen, it is recommended to first lay the products on the floor.

- In order not to damage the tile, its alignment must be done by hand. In rare cases, the use of a rubber hammer.

- If there is a need to cut the material, you should use a tile cutter (not a grinder!).

- To wipe the seams, it is necessary to apply cement-based compounds.

Experts recommend further processing the laid tile with a special polish.Thanks to the wax layer, it will be possible to smooth out minor mechanical damage and prolong the life of the lining.

For how to lay cement tile, see the next video.

Manufacturers

Cement tiles are produced by both Russian and European companies. The most common of them include.

- Luxemix. Russian manufacturer, producing durable and aesthetic materials. When creating products, craftsmen put emphasis on their quality, due to which products are distinguished by high strength properties. The company produces antique materials, tiles for bricks, fragments with various patterns, and also makes coatings to order, taking into account all the requirements of the client for the design of the cladding.

- Bisazza. Italian manufacturer, creating a mosaic for both wall and floor coverings. The company produces tiles with geometric and floral ornament. The molding of the material and its coloring is carried out manually. Above the products work famous designers such as Paola Navone, Jaime Hayon.

- Mosaic del sur. The Spanish company, producing relief tiles, smooth lining and coating using marble chips.The manufacturer offers its customers a wide range of products: materials with a huge selection of ornaments and color palettes.

- Marsalas. A relatively young Russian company, which is gaining momentum in production every year. Produces products that meet European quality standards. Before entering the market, products are tested for resistance to force. Masters of the company are constantly developing new collections of tiles with high artistic requirements.

Every year, Russian and European manufacturers update the patterns for cement tiles, create new, not similar to the previous series, expanding the market of this finishing material.

Consumer reviews

Despite the aesthetics and durability, not many people prefer cement tiles. Basically, this material is chosen by connoisseurs of art. Consumers say that products do not look like mass produced goods. Thanks to the manual work, each piece is unique.

Judging by the reviews, the tile is easy installation, aesthetics, unpretentiousness and ease of maintenance. With it, you can create a bright design that takes in the era of the Middle Ages.. Many say that thanks to the tile they managed to complement the interior, to bring in a zest.

The only drawback that consumers of such a lining emit is its price. No wonder after all hand-made products cannot be cheap. However, those who once decided to invest in the purchase of cement tiles do not regret. Given that the lining can last more than a decade, its cost is justified.