Heat-resistant tile adhesive: features of choice

Heat-resistant adhesive is resistant to high temperatures. Such a mixture is used for lining fireplaces, stoves and heated floors. Heat-resistant adhesives may differ from each other in technical characteristics. Features of choice of heat-resistant tile adhesive will be discussed in this article.

Main characteristics

Heat-resistant adhesive has a special composition and has unique properties that distinguishes such a material from other adhesive mixtures. There are several basic characteristics.

- Good elasticity. She allows to create an equal facing covering.

- Fire resistance A good level of fire resistance is most important for finishing stove and fireplace designs.

- Resistance to temperature extremes. During operation of furnace structures it is impossible to avoid temperature differences, especially if the furnace is located outside the room. The adhesive solution creates a kind of protective layer between the fireplace and the tile material, which helps prevent the deformation of the facing coating.

The composition of high-temperature mixtures includes the following components, which can vary in quantity and quality in one form or another hot melt:

- plasticizers (for external finishing with ceramic tiles, it is necessary to select solutions with a high content of plasticizers);

- synthetic additives (necessary to improve the refractory properties of the adhesive);

- cement-sand mortar;

- chamotte;

- mineral components.

Kinds

The composition of heat-resistant mixtures may include different components, which affects the properties of the adhesive. All heat-resistant compositions can be divided into two main types.

- For facing stoves and fireplaces. This type of glue can be exposed to fairly high temperatures (1200 ° C). The composition of the refractory adhesive mixture includes a large amount of kaolin, which provides a high level of heat resistance.

- For warm floors. Such mixtures are able to withstand temperatures in the range of fifty degrees.

For lining fireplaces and stoves, this type of heat-resistant glue is not suitable.

Heat-resistant solutions have different cost depending on their composition and characteristics. In addition, adhesive mixtures differ in the form of release.

- Powdered mixture. Before finishing works from glue powder, it is necessary to make a solution in accordance with the instructions on the packaging of the material.

- Liquid mixtures. Jelly-like hot melt glue is ready to be applied to the surface.

Popular brands

When choosing a heat-resistant glue, it is important to consider its quality. Before buying a suitable adhesive mixture, it is recommended that you familiarize yourself with popular manufacturers of such materials, as well as with their products and customer reviews.

Stove

Pechnik glue is produced in a powdered dry form. It is designed for finishing stoves and fireplaces. This composition is suitable for materials such as:

- ceramic tile;

- ceramic granite;

- tile made of natural and artificial stone;

- tiled tile

The glue mix "Pechnik" maintains temperature to two hundred fifty degrees Celsius.The complete drying time of the solution is seven days. Buyers have the following advantages of this composition:

- good heat resistance;

- high plasticity rates;

- slow drying, due to which the speed of tile laying may not be too high;

- durability.

Terracotta

Heat-resistant glue "Terracotta" is used to finish both stoves and fireplaces, and warm floors. Work can be done with materials such as ceramic tiles, natural stone and facing bricks.

Glue "Terrakot" has a high level of moisture resistance and heat resistance. The mixture can withstand temperatures up to four hundred degrees Celsius. Among other advantages of the solution can be identified good plasticity and high adhesion.

PalaTERMO-601

The glue mix PalaTERMO-601 is suitable for carrying out internal and external finishing works. Glue can be subjected to temperature effects ranging from minus fifty to two hundred and fifty degrees.

The peculiarity of the product PalaTERMO-601 is that this mixture can be used not only for lining many types of surfaces, but also as a putty or a trowel material for joints.

With the help of PalaTERMO-601, it is possible to seal cracks on the surface of furnace structures. Buyers identify the following positive qualities of this composition:

- good ductility;

- reliability (the adhesive layer does not crack and does not crumble);

- preventing deformation of the tile coating;

- high strength;

- economical consumption.

How to choose

Heat-resistant glue has special technical properties, therefore, when carrying out finishing work, it will not be possible to replace it with other adhesive mixtures. When choosing a suitable heat-resistant composition should consider some of the main factors.

- Place of use. Heat-resistant solutions can be used not only for cladding surfaces indoors, but also for facades. Exterior walls located on the sunny side are also exposed to high temperatures. Adhesive solution for cladding facades must withstand temperatures of at least one hundred and twenty degrees.

- Surface type

- The relief of the base. Depending on the surface structure, you need to select a suitable adhesive mixture of appropriate density.

- Type of tile material.

In addition to the scope of the adhesive composition, it is important to select the mixture according to its characteristics. When choosing pay attention to important indicators.

- Environmental friendliness. It is worth choosing heat-resistant solutions, which do not include toxic components.

- Lifetime.

- Thermal expansion Due to this property, the glue will not crack when the temperatures change.

- Moisture resistance. Such quality is especially important when carrying out finishing works in rooms with a high level of humidity or on the street.

- Drying speed.

- Operating temperature It should be borne in mind that when exterior finishing works, not only the upper limit of the operating temperature is important, but also the lower one.

The adhesive mixture in this case should be resistant to negative indicators.

How to make your own hands

Heat-resistant adhesive mixture can be made independently. The advantages of this approach include low costs for the manufacture of the material and the safety of the composition for health. However, at home it is not always possible to maintain the correct proportions when mixing components.

The main components that are used to make heat-resistant tile glue at home are clay and cement. If clay is used as a basis for glue, it is recommended to add table salt to this mixture. This component improves the moisture resistance properties of the finished material, and also prevents the appearance of cracks on the adhesive surface after drying.

It is better to interfere with home-made clay mortars using a trowel. A construction mixer can degrade the quality of the adhesive mixture.

For laying tile is made a mixture of one part of clay, three parts of sand and one part of cement. Also in this solution, it is desirable to add one cup of salt. In the manufacture of the mixture, special attention should be paid to the degree of clay content. To determine the quality of the material, to create laboratory conditions is not necessary. There are several simple ways to determine the degree of fat content of clay.

- Mash the material in your hand. Sand will not be felt in greasy clay.

- Form a small diameter ball of clay and let it dry. Cracks are formed on the oily clay surface. If the clay is skinny - the ball is not deformed.

- Clay should be stirred in water to the consistency of sour cream.For mixing, you can use a wooden stick with a flat and smooth surface. Depending on the thickness of the clay layer that has stuck to the stick during mixing, the quality of the clay is determined. The thickness of the clay layer of normal fat content will be two millimeters; the thickness of adhering greasy clay is three millimeters; a layer of thin clay will be less than one millimeter wide.

Before making the adhesive mixture, the clay must be brought to a state of normal fat content. In order to give lean skin to fat content, otmuchivaniya is resorted to. The essence of this process is to soak the material in water.

On one part of the clay is taken three parts of water. The resulting mixture should be left for ten hours. Then the solution is stirred until homogeneous and left to stand until a layer of water appears on the surface. The exfoliated water is drained and scooped clay. In this case, the bottom layer does not need to be touched, as it contains unnecessary components in the form of stones or sand.

For facing horizontal surfaces, you can prepare a high-temperature adhesive based on cement.For the preparation of such a mixture will need to mix cement and sand in a ratio of one to three.

Application

Before starting the finishing work, it is necessary to clean the base of dirt and dust, which will improve adhesion. Chips, cracks and other defects on the base must be repaired.

If the surface structure is characterized by a high level of absorption, the base should be treated with a priming mixture before lining.

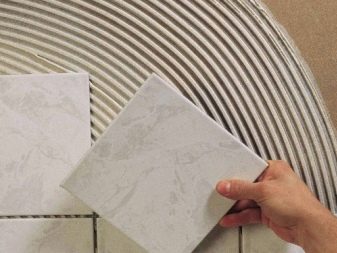

Before finishing work, it is recommended to lower the tile material into the water for a short time in order to improve adhesion to the adhesive. If you purchased powdered glue, then before you start facing, you must prepare the solution according to the instructions on the package.

Finishing work is not particularly difficult. The glue mixture is applied to the surface with a notched trowel. The applied adhesive layer must be no more than one centimeter thick. Then tile is laid on the surface. It is necessary to glue tiled material within ten minutes after glue has been applied to the substrate.

Before proceeding with grouting, it is advisable to wait two days after lining.

You can find out how to lay the tile on the floor heating from the following video.