Primer for walls under the wallpaper: what to choose?

With the advent of new building materials on the market, it became possible to improve the quality of repair and finishing works. The word "euro-repair" has entered our daily life, which means finishing of a special quality.

During construction, an ideal surface cannot be made immediately; therefore, it is necessary to carry out additional work related to refining, repairing, leveling, strengthening. This process is called interior and exterior. Finishing includes installation and finishing works.

Special features

Installation work is the creation of the surface with the help of various plates: particle board, fiberboard, OSB, hardboard, slate, plywood, drywall, wood. As well as PVC material, ceramic tiles, etc. The finishing work includes plaster, putty, whitewashing, painting, varnishing, wallpapering.A very important part of the finish is the application in the work of the primer.

The most important purpose of primers is to increase adhesion. "Adhesion" is translated from Latin as "sticking". This connection arises due to the adhesion of the molecules of materials due to the chemical action of substances.

The primed surface strengthens adhesion of dissimilar materials to the base. It does not allow mold to develop and prevents the formation of fungus, isolates the penetration of rust to the surface, reduces the consumption of paint and wallpaper glue. The use of primer when wallpapering improves the comfort and quality of work and reduces labor costs.

The materials used in the interior decoration, can not do without the mandatory impregnation. This requires a sizing process wallpaper.

Kinds

In the market of building materials there is a large selection of impregnating compositions for priming various surfaces. Their main task is to strengthen the foundation. But there are additional features.

For use with different materials, there are several types that differ in their composition. Some of them are water based.These are acrylic, latex, silicate and silicone primers. Others are made on the basis of gypsum, cement or lime. These are natural materials. There are primers on organic solvents. These are solutions with latex, alkyds or polyurethane.

The purpose of primers may be different, but most often they successfully interchange each other. For example, a deep penetration primer combines both reinforcing qualities and water-repellent and adhesive functions.

Primer classification:

- Insulating. They have in their composition resins or oils, various types of adhesives, which are film-forming substances. Waterproofing layer creates a water-repellent surface, which is especially important before sticking wallpaper.

- Anti-corrosion. Created specifically for the metal, they differ in the impact on the material. When moisture enters the metal a chemical reaction occurs, the material begins to oxidize, which leads to the appearance of rust. It adversely affects the appearance of the room, spoils the wallpaper. To avoid this, various types of anti-corrosion primers are applied:

- phosphating primer containing orthophosphoric acid;

- The passivating primer forms an oxide film. Under the influence of impregnation, the metal takes a passive chemical form, and the film protects it from moisture;

- the tread primer includes zinc dust, which is destroyed by moisture on the metal, thereby protecting the material.

- Universal Primer is an aqueous solution with the addition of chemical compounds. Penetrating deep into the surface, it increases the adhesion of materials, removes small particles of dust. It is universal because it is used for various bases and materials. Suitable for both internal and external use.

- Antifungal primers hinder, and some compounds even actively fight against mold and fungus. At the same time they fasten the surface and increase the adhesion of materials. They can also be used for prevention purposes.

- Primers betokontakt. In the composition they have a filler in the form of quartz or marble sand. They are used to work with plaster or ceramic tiles. For wallpaper, it is not suitable.

Specifications

The characteristics of the primer are usually indicated on the label or packaging of the product:

- what color does it have. In general, primers do not change the color of the coating on which they are applied upon drying. They are transparent. But there is a covering impregnation, which paints the wall in white. This happens due to the content in it of a large number of pigmenting substances;

- consumption in one layer g / m2. This characteristic is needed to select the amount of purchased material. It depends on the surface of the application. If the amount of primer is a bit lacking, and there is no possibility to purchase, then the rest of the solution can be diluted with the basis on which it is made;

- drying time. Each manufacturer is guided by the testimony of the goods. The drying time indicated on the label will not disturb the technical process;

- type of material processed. On the label you can read for what kind of surfaces this type is used;

- type of use. For internal or external works;

- application method.

The remaining parameters can be useful only to narrow specialists.

Which one to choose and why?

For the walls under the wallpaper fit the following types of primers:

- Acrylic. This universal impregnation is ideal for processing wooden, concrete and brick walls. It is made on the basis of acrylic polymers, penetrates deep into the pores of the surface and due to this it strengthens loose materials well. It does not have a strong odor, dries quickly, is environmentally friendly and has a low material consumption.

- Alkyd. Such impregnation has good anti-corrosion properties. In its manufacture used zinc and phosphate. It is environmentally friendly and is well suited for processing metal and wood, walls made of fiberboard, chipboard and OSB. Diluted with white spirit. Not suitable for work with plasterboard and plaster. Due to the content of pigmenting particles in it, it forms a white surface. It can be used as a topcoat.

- Latex. Suitable for all surfaces. Quick-drying.

- Mineral. It is applied to concrete, brick and plastered surfaces. It is made using cement, lime and gypsum.

- Ordinary glue. The cheapest option.

For bare walls apply a deep penetration primer. These are walls made of foam and gas blocks, old lime and cement plasters. After applying the primer, it is absorbed into the base to a depth of 15 mm. It fills the pores, bonding the material and forming a strong film that provides high-quality connection with the finishing material.

Such walls absorb moisture well. Therefore, most often requires the application of a second layer, which need to prime the surface after the first layer is completely dry.

Always apply the primer with a roller and brush. For large amounts of work, you can apply a spray gun, not forgetting about protective clothing and a respirator.

If a There are no special requirements for the base, choose a universal primer. It is latex and acrylic. water based impregnation. They are cheaper than specialized compounds, they dry quickly, are economically spent, and have no chemical smell. The use of such primers (primers) will provide all the requirements.

For wooden coatings choose alkyd impregnation. She hides the resinous bitches, which will not appear for a long time. It is suitable for fiberboard, particleboard and OSB slabs, well insulates iron bases.

Mineral and silicate impregnations are used for plastered, brick, concrete, and foam concrete walls.

Choose a future coverage

The most common type of final (finishing) finishing room - wallpaper. During their existence, little has changed in the method of work. Only additional elements of the preparatory work appeared and the variety of wallpapers expanded.

Wallpapers vary in several types and types.

By moisture resistance:

- ordinary. This paper and acrylic, they do not like moisture and mechanical stress;

- water resistant - tolerant of water ingress to them;

- washable - during operation, non-aggressive detergents can be used in places of heavy contamination and a brush;

- super washable - Basically, it is a different type of vinyl wallpaper, moisture-resistant and wear-resistant.

According to the material and quality requirements of the base finish, on which they will be glued:

- Paper. They are multi-layered and single-layered, show all the defects of the walls, so the base must be perfectly flat and solid. From the glue they get wet and swell. If the base is puttied with sandpaper and not primed, the wallpaper will pull it behind itself and tear it out. An exception might be the overlap sticker method.

To create a single tone used pigmented impregnation. It creates a white surface that prevents the appearance of differently colored areas on the wall. It is easier to work with it, since the unpainted areas are immediately visible;

- Flizelinovye. They are based on non-woven fiber made from cellulosic or synthetic fibers. When choosing wallpaper you need to pay attention to their density. They are light, medium and heavy. The quality of the finish may not be ideal, their density may hide small flaws in the base;

- Vinyl. Due to the vinyl layer on the base they can be used in rooms with high humidity. They are durable, resistant to fading, they can be washed. For them, a relatively flat surface treated with pigmented impregnation will suit;

- For painting. A variety of non-woven wallpaper. Due to the fact that these wallpapers are covered with water-based paint, the substrate must be treated with a primer. If you do not, the wallpaper will move away when painting;

- Liquid. In fact, this is a subspecies of plaster. The price of liquid wallpaper is quite high. To save money, it is advisable to make a flat and durable surface using a sandless plaster and cover it with a primer.

How to use?

When there was only paper wallpaper, to change the interior it was enough to paste new strips of material on the existing ones. Thus, the concrete wall was insulated. Sometimes for this they even pre-pasted newspapers. Now there are many new types of wallpaper for every taste and with different properties. Yes, and the walls have become more diverse.

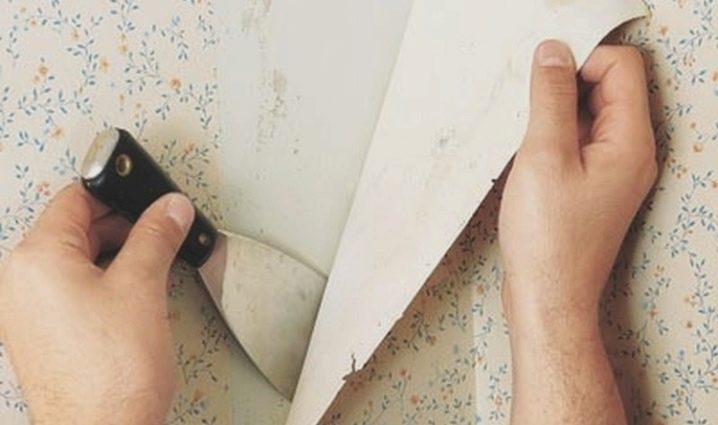

When repairing dismantled old wallpaper. The most convenient way to do this is to use a hand spray with warm water and a spatula. If the outdated wallpaper is badly behind the surface, they can be cut with a sharp knife. Then the water will quickly penetrate them.

Vinyl wallpaper on non-woven base can be removed in two stages. At first the vinyl covering breaks off, and then the residue is moistened with water. Acetic solution can be used instead of water. There are still special tools to help remove the wallpaper.

Priming the surface in this case is not necessary, since the wall is already saturated with glue. The use of primer is necessary for new surfaces.

Surface treatment technology depends on the material of the walls:

Concrete surface

It is necessary to clean it from dust.Cavities from fallen off rubble and the joints between the plates should be puttied and cleaned with sandpaper. It is possible to use diluted glue for impregnation of concrete.

To improve the adhesion, it is preferable to apply universal impregnation, and mineral soil will be suitable for cement mixtures. For a quality result, the walls are spattered bespeschanka.

Plaster

When the plaster is not new, it is necessary to tap it in order to find out if it has moved away from the base. In places of deaf sounds, it bounces off the base. These sites are saturated with a deep penetration primer. After drying, they are plastered.

If the plaster is old or frayed, it must be reinforced with a deep penetration primer. Depending on the condition, two layers are applied. When the foundation is strong, they act in the same way as with a concrete wall.

Drywall

The surface under the wallpaper can not handle. But it is still desirable to cover the drywall with universal primer. It is not advisable to apply the impregnation based on PVA - wallpaper will stick to the base tightly, it will be very difficult to remove them. The seams of drywall necessarily putty.The result is a surface of non-uniform color, which can appear through the wallpaper.

To avoid this, drywall is covered with a thin layer of putty to align the walls around the perimeter. After that, the surface must be primed. To do this, do not interfere with the pigment primer.

Oil paint

Paint is removed with the help of a construction dryer and a spatula. You can get rid of it by chemical means. To do this, you need to purchase a special tool, process the surface and clean it with an iron brush. When used for these purposes, the grinder will have a lot of dust, and the sanding machine will instantly clog the sandpaper.

In order to qualitatively prepare such a wall for sticking wallpaper, you need a putty. To do this, make notches on the wall with an ax, hammer or chisel. Impregnate the base with a universal primer.

After it dries, putty mixture to level the walls. Under the wallpaper just one layer of putty. After drying, putty primer.

If you can not get rid of paint or use putty, proceed as follows.Before you do something, the walls must be degreased. Old painted surface must be roughened for better grip.. To do this, it is treated with sandpaper and impregnated with a universal primer.

It is impossible to glue wallpaper onto painted walls without painting. When applying paint, the moisture contained in it will not be absorbed into the wall. Wallpaper will swell, glue under them sodden and they will fall away under their weight.

Wood and metal

For these bases apply alkyd primer. Metal and wood, varnished, pre-cleaned with emery. The primer is applied in two layers.

For a quality result, the internal walls are putty dry putty. The way to glue wallpapers with overlap is gone Now all the wallpaper stick joint to the joint. To do this, create a perfectly flat surface.

Pelt walls of chipboard, OSB, drywall, cement and lime plasters, covered with oil paint or alkyd enamel. The solution is applied to the walls and ceiling with a thickness of no more than 3-4 mm in several layers. For the first layer, a putty with greater grain is used. Her task is to level the plane.Top cover the final layer of fine grain to give the surface a perfect look.

For work using two spatulas. One is for applying the mixture to the surface, the other is diluted with a solution and applied to the first spatula. After applying the solution on the wall and its drying the surface of sanding paint mesh or fine emery clothfixed on the grout. Dust from rubbing brushes the wall with a broom or brush. Ideally, the use of a vacuum cleaner.

The clogged surface is loose and absorbs moisture very well. It is necessarily impregnated with primer, which contributes to the bonding of the composition and saves the consumption of wallpaper glue.

How to breed?

In most cases, the impregnation is sold in a liquid state, ready for use. But there are times when it has a concentrated consistency. This is done to save tare during shipping.

This impregnation must be diluted before use. It is also available in powder form. The proportions for dilution are specified by the manufacturer. Usually water is used for dilution, but there are cases when chemicals are used as a diluent.For example, alkyd impregnation can be diluted with white spirit.

How long does it dry?

Wallpaper can be glued immediately after drying the primer. Drying time is indicated by the manufacturer on the product label. The amount of time for this depends on external factors: humidity in the room, the possibility of airing (although this is not recommended) and the ambient temperature. Also drying time depends on the impregnated surface. On porous substrates, the primer dries faster.

Different primers differ in drying time.. At room temperature of 18-25 degrees and humidity of 60 percent, acrylic impregnations dry 4-6 hours, alkyd - 10-16, glyphthalic 24 hours. For a deep penetration primer, you will need to wait 12 hours.

Specialists-painters with extensive experience of such works, adhere to their schedule. When working independently, it is better to follow the advice of the manufacturer.

Successful examples and options

The primer can be made with your own hands.

To prepare a deep penetration primer, you will need PVA construction glue and water in the proportion of 1 liter of glue per 8 liters of water. Water is added to the glue, mixing until uniform.It is important to prevent large concentrations of glue. Diluted with water, it should be absorbed into the base. If there is a lot of it, then a film is formed, which will become flaky.

To create a rough base that improves adhesion to wallpaper, add natural chalk or cement and mix thoroughly. 10 liters enough for one trowel. Just in case, the solution is filtered through a two-layer gauze. This primer strengthens and protects the surface from moisture, has an antiseptic effect.

With PVA glue, you need to be careful - over time it tends to turn yellow. It is necessary to avoid getting it on the wallpaper and the joints between them.

To increase the strength of the base and fight the fungus, you can prepare a primer using copper sulfate, wood glue and laundry soap. Due to the fact that the primer will cook on the fire, use aluminum and steel tanks can not, because the vitriol will go with them in a chemical reaction.

In seven liters of boiling water dissolve the soap. It can be crushed beforehand by rubbing it on a coarse grater to reduce the time of dissolution.To the boiling solution add wood glue and copper sulphate. Thoroughly mix and boil the primer over low heat for about half an hour..

Every five minutes, stir the solution to avoid the appearance of lumps. Thirty minutes later, the finished primer is filtered through a sieve. When the solution has cooled, the primer is ready for use. Such a primer is suitable for strengthening block, brick and plastered walls.

To improve adhesion, it is possible to prepare a universal primer of alum (aluminum-potassium), chalk powder, drying oil and dry paint glue. Mixing thoroughly, bring the mixture to a homogeneous mass.

If the primer turns out too volatile, then it is diluted with hot water to the desired state. It is not necessary to filter this primer.

It is impossible to keep the solution for a long time, it will quickly lose its properties, so it is prepared immediately before use. Such a primer is suitable for any glossy or painted surface, for example, glass, hardboard, metal, tin sheets.

Important points

The primer can be made independently, but it is better to use a professional industrial composition.It is produced ready for use, in the form of a powder that is diluted with various bases or concentrated.

It is necessary to use a primer before it loses its properties.. When using PVA glue, you need to be especially careful: getting to the joints of the wallpaper, it leaves a trail. Be sure to ensure that the primer does not fall and does not dry on the window glass. It is impossible to get rid of its splashes chemically, it is removed only by a mechanical method, but the glass will inevitably be scratched.

You also need to keep furniture and flooring. When using a water-based primer, iron elements may oxidize, and rust will trickle through the wallpaper. Such places need to be pre-insulated with oil paint, varnish, glue with foil. Priming should be done while avoiding a temperature drop in the room. This should be followed when sticking wallpaper.

For more tips and advice on how to properly ground walls, see the following video.