Subtleties laying tiles on drywall

The massive use of a new type of building material - sheets of drywall - raises many questions from builders who have not previously encountered this type of work. One of the topics for discussion is how to lay ceramic tiles correctly.

Special features

Everyone knows that wall and false panels are successfully painted and pasted over with wallpaper. But the plasterboard drywall raises concerns and disagreements among experts. If the masters are incompetent in this matter, then they may even abandon the facing works on drywall, arguing that the tile will not hold. In order to thoroughly understand this issue, one should study the features of the base being prepared, the types of adhesives that cope with the work, and know the nuances of the technology.

The main requirement for facing works is a perfectly flat base surface without hillocks, cavities, cracks, chips.Previously, construction mixtures (plastering and putty) were used to fulfill this requirement. But progress does not stand still, and plasterboard panels are becoming the most popular. They are easy to install, their installation does not take much time, its technology is very simple. You can forget about dirt, debris, dust in the air, a long time of drying material.

To correctly determine the type of drywall offered by construction stores, you need to know the future purpose of the room, the conditions for its use. Material is of several types:

- usual;

- moisture resistant;

- fire resistant

In this way, for the construction of false walls and partitions suitable standard drywall. In conditions of high humidity in areas such as bathrooms, swimming pools, you should use a moisture-resistant look. The scope of fire-resistant drywall is quite narrow - it is warehouses, special industrial premises.

To mount the drywall, you must first prepare a metal frame that will hold the entire structure.It consists of several types of metal profiles and additional fasteners. Previously, the sheets were attached to the crate of wooden beam, but this process is not technologically correct and its operation in wet conditions is unacceptable.

Kinds

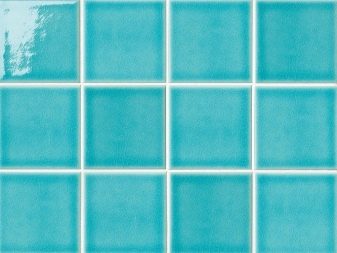

When choosing a tile, you need to pay attention to its technical features:

- The pattern on the tile should be perfect. That is, there must be a clear, non-smeared pattern without streaks.

- Smooth outer side. You can not find a perfectly smooth tile, there is always a bit of error, but you should pay attention to it when buying. In the store, you can conduct a simple check: connect the two tiles with the outer sides. Then it is possible to evaluate the pros or cons of the selected tile.

- Absolutely right angles of the tile.

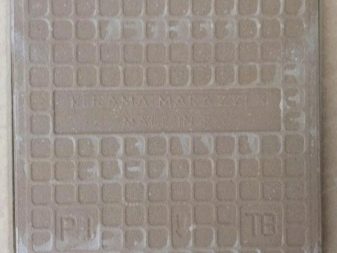

- The downside of the product also deserves attention when choosing. Firm - manufacturer and name should be visible.

- It is difficult to determine the strength of any tile, except overpowered, which is visually fragile.

But there is a way: when struck, a muffled sound indicates that the tile is of proper quality.

It is better to calculate the required material one by one, and not by quadrature. It is necessary to take a tile with a margin of about 10%. Experts advise to take everything from one batch so that there are no differences in color.

Currently, manufacturers of dry mixes provide customers with a decent and wide choice of material with which you can veneer drywall. Choosing the type of suitable glue, you should be guided by the following tips:

- It is difficult to determine the strength of any tile, except overpowered, which is visually fragile.

- The adhesive must be suitable for the type of substrate.

- He must be first-class so that it is comfortable to do the work.

- Glue must be safe. This is important during the work, as well as during further operation.

When you need to tile large areas, it is better to choose specialized adhesives. In the construction market there is a huge variety of them - from the simplest to complex mixtures with various additives for each type of tile.

Cement-based adhesives should contain additives that increase the elasticity of the mixture. It is also possible to glue with a plastering solution.In rooms with high humidity, it is advisable to use a moisture-resistant mixture.

Synthetic adhesive bustilat, not quite suitable for such purposes. Its main disadvantages are shrinkage and high fluidity. They can not hide the surface irregularities. But you can use it when the base is flat.

Construction glue or nails on a water dispersion basis should be used for repair work. They do well with different tasks, but the consumption over large areas is extremely large, so their scope is narrowed.

Before starting work, you should read the instructions for the selected type of glue. The information obtained will provide a qualified and technically competent approach. On the clinker tiles and aquapanel can be applied to almost all types of glue.

Surface preparation

Preparatory work is an indispensable part of the process of future lining. If the technical conditions are not met, such coverage will not be durable.

You need to start with the basics, that is, with the installation of drywall. First you need to calculate how the sheets will be placed on the wall, taking into account window and door openings. It is preferable to start the installation from the corner with a whole sheet, as this will reduce the amount of waste.

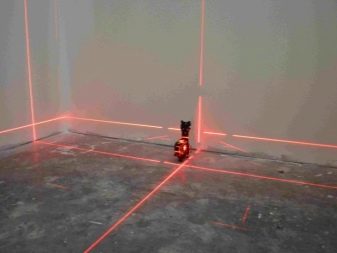

After that, you need to put the markup, where the metal profiles will be attached.

Vertical guides come in 1200mm increments. A perimeter is used UD profile. The assembly of the metal frame is a very important process that can affect the performance properties of the tile. For example, the larger the tile in size, the more often it is proposed to put a profile, the step will be not 1200mm, but 400mm.

The frame is additionally soundproofed with a special tape. GCR sheets are attached with screws. After our canvas is ready, you can proceed to the next stage of preparation.

It is necessary to inspect the plasterboard lining of the surface for the presence of hidden defects: leaks in the joint, protruding heads of screws, holes and dents on the sheets. All this needs to be eliminated before the putty work. Your task is to process and seal the seams in plasterboard. It depends not only on professionals who are engaged in this business, but also on a number of factors:

- moisture level in the room;

- temperature drop;

- drafts.

Spackling work performed at a temperature of + 10 ° C.

With the help of a knife for drywall need to embroider the joints. Then it is necessary to treat the seams with a putty. First, the base layer is applied, filling the voids, after it a special tape is glued - serpyanka. This is the prevention of surface cracking. It is embedded in a layer of putty, sanding is necessary if there are protruding parts.

For better adhesion of bases, apply a primer layer to the surface. The choice of primer type is determined by the type of glue used. As a rule, you need two, or even three layers of the solution, applied by a roller or a wide brush. Each layer should dry well. In the composition of the primer is welcome the presence of an antiseptic additive.

The last stage of preparation is a sketch of the placement of the tile. It is necessary to calculate how many rows of whole tiles there will be, and how many are cut, to determine the thickness of the inter-tile joints. With the help of the tile cutter it is necessary to cut the tile. The surface is marked level.

DIY assembly process

The tools used are a tank for plaster, a flat trowel, a trowel with teeth, a rag and an absorbent sponge, level, crosses for a tile, a rubber trowel for grouting.

General scheme of the procedure:

- Dilute the adhesive to the desired consistency using the instructions on the packaging.

- The mixture is thrown with an even trowel and is spread over the square where the first tile will be located. The notched trowel makes furrows on the area to be treated.

- The tile is moistened with water from the cement base and covered with a thin layer of mortar.

- Tile attached with glue to the selected location. The level checks the evenness of the future laying.

- If, when pressing on the tile, excess glue crawls out, this means that the amount of the applied mixture is calculated incorrectly. It must be removed with a spatula.

- To make the joint in the inter tile space perfect, you need to use special crosses for the tile.

- The prepared elements are glued in rows. The second row begins when the first is completely over.

- At the very last moment deal with those areas where trimming is required. For example, the last row is left for later. It is convenient to work with him when the flooring is already laid.

- Excess glue on the front surface is removed with a cloth.

After completion of the laying work, the web should be allowed to dry for several days. Do not rush to the next stage of work, until there is a good adhesion of gypsum boards and tile flooring.

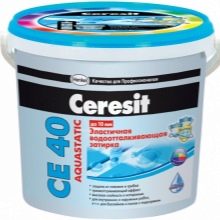

The final element of tile laying is mashing joints. In addition to technical purposes, the seams perform a decorative function. On the market of building materials are grout a variety of colors and shades.

The main stages of filling the seams:

- Water is added to the dry mix. You must immediately mix the solution thoroughly with a drill and mixer. It is sometimes difficult to do this manually. This is especially true of moisture-resistant grout.

- Then you need to give the mixture a little time to settle and stir it again.

- Apply the solution to a wall or floor.

- Remove excess.

Laying tile on drywall is not at all difficult if you follow the above tips. First you need to attach the door box, and then just start revetting the rest of the walls.

On drywall, you need to thoroughly putty all irregularities to make the mount more reliable.

Useful tips

If work needs to be carried out in a small room, then follow these rules:

- The size of the tile should not be large, it is preferable to use a mosaic tile.

- Use light shades of tiles, they will visually expand the space.

- Glossy surface looks more advantageous.

- The scheme of a set of tiles - horizontal.

- If the room has a high ceiling height, the tile is laid only in a vertical way.

- Decorative finishes, drawings, should be at a level accessible to the eye.

- The upper rows of tiles are not pruned.

The most important thing is to strictly follow the technological process, and then laying tiles will be an easily accomplished task.

Only moisture-resistant drywall is suitable as the base for tiles. If conventional is used, the profile racks should be positioned in 400mm increments. Sometimes the base is reinforced with a polypropylene mesh so that the drywall is not subsequently bent. Adhesion of glue to the base will be maximized if diluted to the desired state (consistency of thick cream).

The tile is pressed to the surface by hand, but if its size is large, then you can additionally use a rubber hammer. Up to five lanes can be laid in one pass. Then you need to stop for an hour.

The finished canvas should dry at least for a day in order for the polymerization to take place in the glue, and it fixed the tile well.

The next layer after grouting should be hydrophobic impregnation, which will protect the space between the tiles. Impose need carefully. In conditions of high humidity need to use silicone sealant. Choose a composition with antimicrobial and anti-mold additives.

Tips for cutting tiles:

- Cutting the desired element or simply cutting off the part is easy if you have a tile cutter.

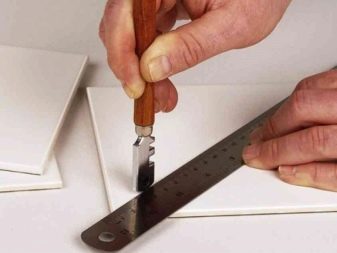

- With the help of a glass cutter, a line is marked on the tile, it is pressed, and then the tile can be broken along the seam.

- If you need to make the configuration of an irregular shape, use a pattern of paper. Then it is applied to the tile, and with the help of a vice, pliers and a glass cutter the necessary element is cut.

- Also used in the jigsaw or grinder.

For how to lay tile on drywall yourself, see the next video.