Grout for Ceresit tiles: types and colors

Grout for Ceresit tiles is represented in almost all stores of building materials. However, due to the variety of options, many buyers are faced with the problem of choice.

About what types of grout Ceresit exist, and how to choose the appropriate composition, tell this article.

Kinds

The range of Ceresit is represented by the following types of tile grout:

- CE 33 Super - used for processing thin seams (up to 5 mm).

- CE 35 Super - it is applied at thickness of seams of 4-15 mm.

- CE 43 Super Strong - durable and elastic grout, suitable for processing joints 5-20 mm.

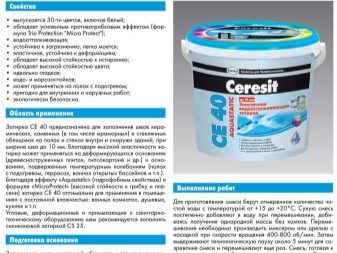

- CE 40 Aquastatic - has an elastic structure, designed for seams no more than 10 mm.

- CE 79 UltraPox - the grout from 2 components possessing high chemical resistance.

- CS 25 - Silicone grout with sealant function, ideal for processing joints between bath / sink and tile.

How to choose

The choice of Ceresit grout depends on the needs of the consumer. Below are some characteristics of brand products that must be considered when purchasing.

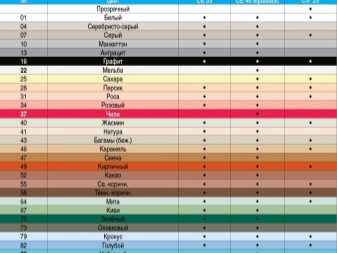

The widest range of colors are those with the names CE 33 (26 colors) and CE 40 (30 colors). CE 40, CE 43 and CS 25 groutings are hydrophobic and resistant to dirt. CE 33 and CE 35 groutings are used in conjunction with antifungal impregnation for CT 10 seams. It is also recommended to use in combination with CT 10 for treating seams in wet rooms and for exterior cladding of CE 33 and CE 35 structures.

All types of grout Ceresit are water resistant and resistant to atmospheric agents, including solar radiation.

The choice of grout depends also on the surface material. When processing seams on the floor in a high-traffic room (in the garage, shop, at the entrance to a private house) should use the product Ceresit CE 43.

For glazed ceramic tiles CE 33, CE 40 or CS 25 are recommended. For unglazed stoneware tiles, clinker and natural stone (except marble) any Ceresit grout will do.For marble tiles, CE 40 will be the best choice.

To work with glass mosaic any Ceresit products (except CE 35) will do. However, CE 79 grouting is usually used in such cases. For processing seams on the surface of a decorative stone and bricks worth using Ceresit CE 35, CE 43 or CS 25.

Color spectrum

If the grout color is extremely important to you, then consider the color range of CE 33 and Ceresit CE 40 products.

You can choose a color from the base set:

- white;

- the black;

- brick;

- dark brown;

- green;

- Navy blue,

Or you can choose the appropriate option from four shades of gray, four shades of pink, three shades of green, four shades of blue and a large assortment of beige-brown tones.

If you need to achieve a visual effect of a uniform surface structure, then you should choose a mixture in the background color or pattern. If you want the separation of the surface into separate elements to be noticeable, a good choice would be a contrasting grout Ceresit.. When using small mosaics using grout in different colors, you can achieve geometric or abstract compositions.

On the official website of Ceresit, you can use the selection of grout online. To do this, simply select the color of the tile used (or the closest shade to it) and select the color you like for the trowel mixture, observing the combination options on the screen in online mode. You can also switch between tile and mosaic modes.

Material consumption

Calculate the consumption of grout firm Ceresit is easy. When calculating, it is necessary to take into account the type of surface being treated and the conditions of its operation.

For a correct calculation, you can use the formula. The length of the surface to be processed needs to be folded with its width, and the result divided by the product of these quantities. The resulting number must be multiplied by the thickness of the tile and the seam width. The result will be the mixture flow rate in units of kg / m.

You can also use the information specified by the manufacturer on the package, or use the average consumption:

- CE 33: from 0.4 to 0.5 kg / sq m;

- CE 35: from 0.4 to 1.2 kg / sq m;

- CE 40: from 0.2 to 0.5 kg / sq m .;

- CE 43: from 0.9 to 1.5 kg / sq m;

- CE 79: from 1.0 to 1.3 kg / sq m;

- CS 25: from 25 to 100 kg / sq. m.

Instructions for use

Proceed to the treatment of seams can be after the final hardening of tile adhesive. The time interval can be different, depending on the type of composition, but in any case it is at least 7 days.

The edges of the tile must first be cleaned from the remnants of tile glue and dirt. To ensure better adhesion to the surface, the edges can be moistened with a sponge (only for cement grout). If you are working with a long-faced surface, the old grout must be completely removed. When working with unglazed tiles, it is recommended to check the interaction of tiles and grout for surface staining.

Working with grout mixes Ceresit includes two main steps: the preparation of the mixture and its application. However, there are some nuances concerning the use of different types of material.

Do not forget about precautions when working:

- be sure to use skin and eye protection;

- ensure good ventilation of the room.

Cement grout

For mixing the mixture, the manufacturer recommends using 15-20 degree water. It is necessary to measure the required amount of water and, stirring, gradually pour the mixture into a container with water. When preparing a large amount of the mixture, it is better to use a drill or a mixer for stirring. Wait 5 minutes and mix again. Then you can get to work. It is recommended to use ready-made cement mixture for 1 hour.

Relief tiles must be glued with a film or tape to prevent the grout from getting into the relief. The grout is applied with a rubber spatula and rubbed into the seam with cross-shaped movements. After collecting the surplus operation is repeated.

When the mixture is slightly "grabbed" (maximum 10 minutes), you need to carefully walk on it with a wet sponge. It is important to avoid excessive contact with water, otherwise the grout may change the tint.

After complete drying of the seams (after 24 hours), the surface should be treated with a dry, soft cloth. The stains are removed with a clean wet rag or felt mitten. It is worth remembering that wetting grout earlier than one day after the treatment of joints is not recommended.

Epoxy grout

Not everyone knows that Ceresit also produces silicone and epoxy resin-based trowels. Product CE 79 has its own characteristics of use.

An important point when using epoxy grout is its proper mixing. Inside the package are bags with two components that need to be combined, strictly observing the proportions.Then the mixture is stirred with a mixer at high speed.

As in the case of cement grout, It is advisable to prepare a mixture with an epoxy compound in small portions, since after 1.5 hours it becomes unsuitable for use.

A rubber spatula is used to work with epoxy grout. Care must be taken to keep the work surface dry. You also need time to remove excess mixture from the surface. The remnants of the composition cleaned exclusively with a special sponge.

It is also recommended to purchase a special tool for cleaning the surface of the "plastic" plaque after work. Eliminate traces of the mixture in another way will not work.

Silicone Grout

When working with silicone grout, it is recommended to close the adjacent surfaces with masking tape, and place a bundle of polymer in the expansion joints. Then you need to cut off the end of the cartridge with grout, while maintaining the thread, and twist the tip. The tip of the tip is also cut to approximately the size of the seam being machined. Next, the cartridge is inserted into the gun, and begins uniform filling of the seam.

After 15 minutes it is necessary to slightly treat the seams with a soapy sponge.and then smooth out with a spatula to remove excess. Spatula is also recommended to moisten. Then you can remove the masking tape. At the end of the work, ensure that the room is well ventilated and left, as the drying of the silicone grout results in the release of acetic acid. If for some reason fresh grouting needs to be removed, alcohol or acetone should be used. After the composition has hardened, it can only be removed mechanically.

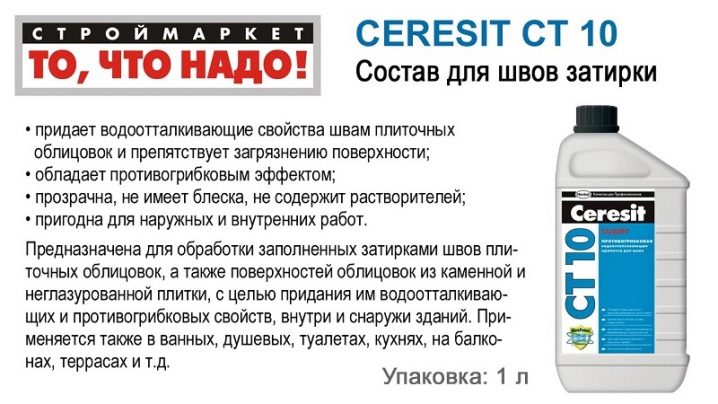

Hydrophobic antifungal solution

The range of Ceresit firms includes the transparent repellent CT 10 Super. After treatment with this solution, the seams acquire water-repellent properties and protection from contamination and fungus. The product can be used in conjunction with other grouting or independently, suitable for fillet and expansion joints.

Impregnation is applied with a brush in completely filled seams. If necessary, the seams can be pre-restored. A maximum of 15 minutes after applying the excess solution should be removed and "walk" on the surface with a wet rag. Dried impurities will have to be removed with a solvent.If the seam is already affected by the fungus, then you should first remove it with a metal brush, and then, after removing the dust from the seam, apply the CT solution.

Reviews

Buyers are positive about Ceresit moisture resistant grout. They note the excellent technical characteristics of the products, the ease of carrying. Pleases buyers and a diverse palette of colors, and the fact that the composition dries quickly. At the same time, the coating pleases the owners for a long time, without losing their qualities.

For information on how to use Ceresit grout for tile joints, see the next video.