Interior corners for tiles: types and uses

The most common type of finishing material, which is used for decorating the bathroom and sanitary facilities, is ceramic tile. To complete the completeness of the appearance and give aesthetics to the room, professionals began to use special corners for tile material in the bathroom.

The main task of such devices is the masking of all existing flaws that appeared during facing works, as well as the protection of corners from mechanical impact and the appearance of fungus.

Where do they apply?

Most professionals use plastic corners for tiles, using the method of grinding the edges of a tile at an angle of 45º. That's just such a procedure requires skill and responsibility. It is better not to apply this method if the facing process is carried out independently by a person who has no experience in such works.In this case, for self-styling it is better to find corners for tiled material, which are called "layouts".

Such elements will be indispensable during the facing of the steps, the outer corners of the bathroom and the kitchen apron. Usually used for this plastic layouts, which are sold in a large assortment of colors and shapes.

External layout

The most popular type of tile corner is considered an external type of layout. This product is intended for decoration of the outer corners of the room. Distinguish the external layout of the dimensions, selected by the thickness of ceramic tiles. The most common are the corners of 11, 9 and 7 mm. The typical length of the products is 2.5 m.

On the one hand, the layout has a groove in which the tile material is installed. The other side of the layout with a decorative type of surface gives the outer corners completeness and aesthetics.

The use of such material helps to protect the outside corner from various damages.

In the manufacture of corners apply the following materials:

- brass;

- aluminum;

- plastic.

Mounting technology

Mounting of external layouts made of PVC, also called “trims,” is performed after finishing the facing of the wall forming the outer corner.

It is necessary to perform the work according to the following algorithm:

- Before starting the facing work of the second wall, the trim groove should be inserted into the tile slab with which the other wall of the room is faced. At the same time, it is necessary to strictly observe the dimensions of the groove in the dimensions of the tile — otherwise, with a smaller size of the groove, it will not work. For larger grooves, you will need to use more sealant.

- For convenient implementation of the finishing of the next wall, the corner must be fixed with adhesive tape.

- Tiled material is placed tightly against the layout - you must always control the vertical level.

- At the end of the work should be sealed voids, using acrylic or silicone glue. Smear seams need to be very careful that there was no extra space.

Trimming

When mounting trim trimming is necessary in cases where they expect to equip suspended ceilings. After the trim (profile) installation is completed, trimming is much more difficult.To fix the corner in the doorway, you need a masterful skill.

Usually, trimming is needed when the angles are perpendicular to each other. Trim trimming is carried out at a 45 degree angle for cladding an outer angle of 135 degrees. Work must be done very carefully, because any deviations will lead to the appearance of a cleft at the junction.

Also, sloppy work will lead to the appearance of a burr, which will not allow the corners to sit tight.

In such a process, the block will provide an excellent helper, providing a more accurate location of the layout at right angles. Themselves cuts are made with a hacksaw or using an impeller.

For perfect cropping you need to have experience in this business. Consequently, it is necessary to proceed to the work with all seriousness, after making measurements and marking. With the existence of differences in the geometry of the section of the resulting angle should be sharp.

Repair or complete replacement of the layout

If you wish to change the layout due to the appearance or the existence of damage, you need to repair the trim or make a complete replacement.This process is quite complicated, but you can still do it. For this:

- the damaged element is carefully cut off without damaging the ceramic tile;

- preparation is underway: trim trim;

- it is necessary to protect the plane itself, pre-protecting the tile material itself;

- The layout is established using a binder, such as glue.

Internal Layout Type

The outer type of trim carries a significant functional load, while the inner one is used much less frequently. The need to use the internal trim is eliminated if the corners of the room are derived below zero.

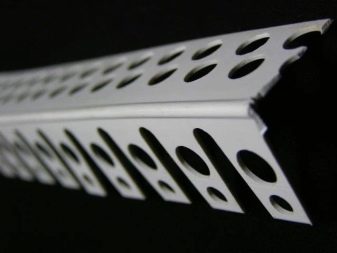

The structure of the internal trim is characterized by the complexity of the design. It consists of the following parts:

- groove for ceramic tile;

- perforated protrusion;

- decorative concave fragment.

The mounting of the internal corners to the tile material should be started after full lining of one of the walls. Then the layout is tightly applied to the facing side. When finishing the next wall tile lead into the groove of this corner, and then strongly pressed. Even with a fairly dense installation, voids are formed.Finishing work, such voids are usually sealed with glue.

Most experts carry out the installation of plastic layouts a simple method. Since the interior corners usually have a decorative function for installation with a tile in the bathrooms, they should be installed after facing the walls that form a right angle. On each layout, a perforated ledge is cut, the corners are put on, gluing to the tile itself.

This technique has its advantages:

- simplified installation step;

- possible installation at the end of the finishing of ceramic tiles.

Step corners

When finishing the steps, corners are especially important. First, they improve the appearance, and secondly, such a material will ensure the durability of the facing steps.

Corners used when facing the steps can be of two types:

- similar to the wall;

- invoices.

The first type is used in works very rarely. The reason for this is the weakening of the angle of the step when installing the corners, which greatly reduces the service life. In addition, moisture is delayed, pollution accumulates.

The most efficient is considered to be the type of corners.. Such devices can ensure safety by preventing the slipping process.

Usually used metal patch corners.

Machining joints

Even with a tightly mounted bathroom to the wall, small crevices remain in the junction area, which must be sealed with a sealant before mounting the corners. In this case, the best option would be to use an aquarium version of the sealant. It is possible to begin works after full drying.

It is better not to carry out the mounting process alone, as it will be easier to carry out such work with an assistant. Assistance will be needed to ensure the required accuracy of laying the slats. Besides, to achieve high quality of the work performed will allow the density of pressing the corners over the length - only in this way it will be possible to make good bonding of two surfaces.

In order not to spoil the enamel coating, the masking tape is glued to the edge of the bath itself.. After this, the slats should be cut based on the dimensions of the installation zone, then you need to apply “liquid nails” or other similar composition to the corners.Lay this type of slats directly on the edge of the bath, while strongly pressing them against the bath and the wall.

From the efforts will depend on the reliability of bonding, as well as the tightness of all joints.

Ceramic type of corners

In order to increase the quality level of facing works, as well as the durability of the facing surface, special ceramic corners are used, instead of ordinary plastic ones.

The peculiarity of the physicochemical properties of the ceramic corners is their high strength. Products for a long time retain excellent external qualities. Durability and hardness, as well as moisture resistance, have a great effect on reliable operation.. Such products are characterized by color fastness, because plastic products grow turbid or turn yellow after some time.

The disadvantages of ceramic products include the inability to withstand significant loads, which are characteristic of operation. The fall of various objects and blows lead to the appearance of holes, chips. Therefore, applying ceramic tiles for facing works, you need to act as carefully as possible.

For more information on interior corners for tiles, see below.