Ceiling tiles: features and varieties

Ceiling tile is a unique finishing material, through which you can easily perform self-installation of the ceiling is not worse than professional craftsmen.

To know how to do this, it is necessary to find out the nuances of each type of such products and explore the small tricks of quality and simple work.

Special features

Ceiling tiles are not a single PVC-based material, as many mistakenly believe. This is a mass of species with a number of characteristic features. All categories are united by the method of fastening to the base of the ceiling, which is carried out by means of glue solution on the prepared surface. Regardless of the type of raw material used in the lining, the preparation of the base is identical.

The material used in the design of cladding, is lightweight, which allows you to work with the ceiling area without the use of additional fasteners. Such a finish is considered an alternative to stretch and plasterboard ceilings., the look of the finished canvas looks elegant and stylish. To carry out the finishing work, the metal frame is often not needed, even if relatively heavy grades of ceiling tiles are used in the work.

It will take no more than 1 day to complete the finishing, except for preliminary preparation of the foundation.

Due to the low weight in the performance of finishing work, glue is saved, which is applied pointwise. In this case, there is no need for additional application of the adhesive substance to the ceiling surface: usually such compositions keep the material well while observing the finishing technology.

Such the finish has a long service life: it lasts for 10-15 years without the need for adjustment, if you treat the coating carefully. In most varieties of the surface, you can give a fresh look, if necessary, changing its color to match the wall covering, taking into account the change of interior design.

Advantages and disadvantages

The ceiling tile has a lot of advantages:

- it is produced on modern equipment using new technologies, thanks to which it differs in structure and has good operational characteristics;

- tile has several categories differing in the composition of the raw materials used, which can be natural or artificial;

- the material can be of different shapes, which allows you to choose various options for finishing the ceiling, taking into account the chosen style and non-standard types of the ceiling zone;

- it is easy to install: it allows you to perform it efficiently due to the optimally convenient size;

- regardless of the type of material, the ceiling tile strengthens the base of the ceiling and warms it, which is especially felt during the cold season;

- the tile is soundproofing the room, saving the household from annoying extraneous sounds coming from neighboring apartments;

- has a wide variation of the picture, as well as texture, which allows it to be used in the same style with the furnishings as a support for the desired pattern;

- such a finish has a lot of color shades, and in some varieties it allows repeated surface staining using a conventional color scheme;

- Ceiling tile is a versatile material that can be bought at any hardware store, while having a wide range of cladding for every taste;

- some varieties of this material are suitable for wall decoration;

- There are varieties in the assortment for which it is not at all necessary to level the ceiling to perfection;

- The material is characterized by an acceptable cost, so buying a large quantity will not hit the family budget.

The texture of the ceiling tile is also noteworthy: it can be smooth, rough, embossed or laminated. This material is able to imitate textiles, metal and wood. To such a tile is easy to choose a baseboard, corners and sockets in the same style. Based on the type of material used, the thickness of varieties varies from 3 to 14 mm.

This decoration fits perfectly into the interior of different rooms: it can decorate the ceiling of the living room, children's room, office, kitchen, corridor, hallway or bedroom. At the same time for each room you can pick up varieties with a special pattern and texture. A wide range and demand are explained by the environmental friendliness and safety of many varieties of large producers.

With many advantages, this facing has several negative sides:

- the material is not always identical: he often needs calibration, which slows down the finishing work;

- ceiling tiles of porous types can be deformed, so before buying it is important to take into account the type of glue;

- Not every type of glue can be removed from the front surface without damaging the material, so the work should be carried out as accurately as possible;

- fragments of synthetic material are quite fragile: when adjusting the angles, they can break, which increases the scrap rate;

- Some materials do not have even angles due to tight packing, which tightens the corners and makes them dull, which leads to the formation of cracks and voids.

The disadvantage of the porous categories is shrinkage when applied to the surface of the adhesive composition and the manifestation of glue on the front side of the lining. Also, some species have a pattern in a certain direction, so often fitting the joints is difficult.

Besides, it is not advisable to glue the ceiling tile to the base of the ceiling immediately after purchase. It tends to accumulate moisture.

To further this material did not sit down, it is necessary to remove from the packaging plastic film,leaving them for two or three days in a dry room.

Kinds

Ceiling tiles have a special classification by production method. There are three types of material, which will be discussed below.

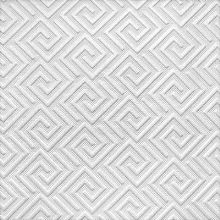

Stamped

This group includes material on the basis of sheets of expanded polystyrene, which are pressed to the desired thickness (5-8 mm), causing a relief pattern. This tile is distinguished by a porous base and a loose structure. It is characterized by white color, the possibility of staining with water-based paints and even with shpakryl.

The advantage of the material is the low cost and ease of manufacturing technology.

The disadvantage of this finish is fragility. Besides that it must be cut with a sharp knifeWhen combining and adjusting, the corners can easily break off - this increases the number of defective parts and glue consumption. The surface of such a tile is opaque, not having a protective film, therefore during operation it does not provide for wet cleaning or cleaning. It gets dirty pretty quickly.

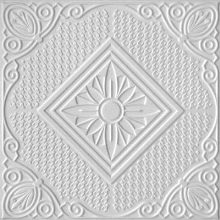

Injection

This facing material for ceiling decoration is made using a different technology, thanks to which its price is higher.It consists of polystyrene granules, which are placed on a special form and sintered.

Unlike a stamped analog, the structure of such a ceiling tile is distinguished by its density and fine grain size. It is stronger, does not require special thrift in the work, it is easier to cut, while it almost does not break. The drawing on its face is expressive and relief.

Tile thickness is from 9 to 14 mm. It is the best protection against noise and heat loss and is especially good at hiding minor irregularities in the base. The joints between such tiles are not as noticeable as those of stamped counterparts, so the finished surface looks monolithic when finished. This tile can be washed. The structure is white or painted.

Extruded

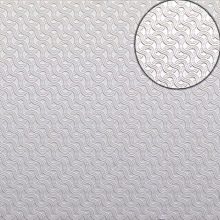

This type is the thinnest type of ceiling tile. With a thickness of 2.5-3 mm, it is quite strong, differs in big service life. It is created from foamed mass by extruding through special openings with the subsequent application of a drawing, paint or polymer film.

This type of material is characterized by density, has a smooth surface, due to which such a tile is often called laminated.

This material is quite expensive. The product is hygienic, resistant to wet cleaning of the surface and the accumulation of dust that can repel water. In addition, it does not deform and returns to its original shape when pressed. If necessary, such finishing materials can be used for work in the bathroom.

The advantage of this type of finishing material is the ability to imitate wood and marble.

Materials

In the production of ceiling tiles use different raw materials. The material is significantly different from the ceramic and plaster analogue, which has a large weight.

The main materials used for the ceiling are:

- polystyrene foam;

- mineral fiber;

- metal;

- tree;

- plastic.

By type of surface materials are glossy, matte and mirror. Matte and glossy are designed primarily for living rooms, mirrored suitable for office space.

Models are hygienic, acoustic and moisture resistant. PVC varieties are more like plaster stucco. Mineral fiber is performed with the addition of cellulose, it is necessary to work with it carefully to prevent the formation of dents.

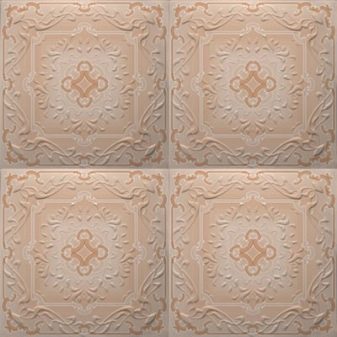

Metal tile Aluminum and stainless steel can be matte and glossy. It is durable and wear-resistant, often has a mirror coating, perforation, powder coating.

Wooden crafts for the ceiling is made on the basis of different types of wood, as well as MDF, chipboard, veneer coating, plywood and lamination.

Plastic tile characterized by a smooth structure and resistance to temperature changes. It has a glossy surface.

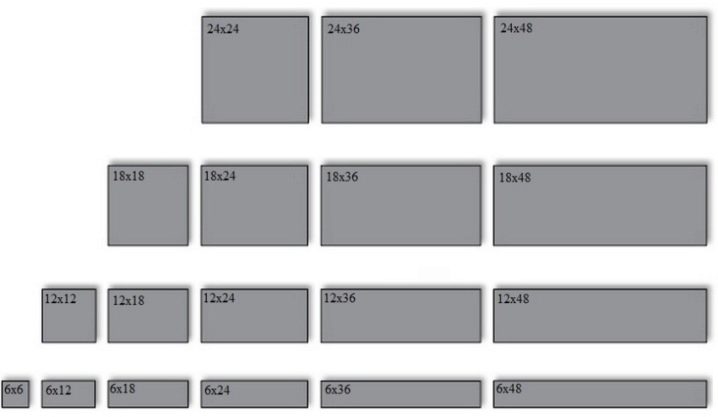

Dimensions

Dimensions of ceiling tiles depend on the standards set by the manufacturer. Initially, a tile with standard dimensions was considered a product 50x50 cm.

Today, the dimensions are subject to the manufacturing material:

- wooden - 30x30, 50x50, 30x70, 20x60, 60x60 cm;

- from metal - 30x40, 30x60, 40x40, 50x50, 30x70 cm;

- from expanded polystyrene - 30x60, 40x40, 30x70, 50x50, 40x60, 40x70, 60x60 cm.

In addition to the standard sizes, the ceiling tiles are also made to order, so its dimensions can be up to 2 meters long. The expanded polystyrene tile can be quite small (30x30 cm) or large (1200x600 mm).

Forms

The traditional form of the ceiling tile is considered to be square, since it is convenient in operation, and due to this shape it is easier to lay (especially in the corners) and also to perform the calculation.

In addition, in production today there is a finishing raw material of rectangular and non-standard shape. If some species are more close to squares and have wavy side faces, then others can hardly be called geometric shapes. The design approach leads to the fact that the shape of a turntable is obtained from a square, a tile with 6 corners more resembles two inverted shields. Such materials are harder to lay: you have to combine them, turning the fragments strictly perpendicular.

Colors and decor

In today's market of finishing materials, ceiling tiles are available in a wide range of colors, the color of which depends on the type of material used. Porous polystyrene varieties often white, extruded tiles can be colored: white and blue, pale pink, light green, cream, coffee, milk and beige. If it imitates another raw material, the color may be marbled, like ivory, brick, wood, or leather.

Wooden varieties are made in shades of beige and brown colors. Metal counterparts are notable for the rich tones of the palette.They can be emerald, golden, silvery, copper, chocolate with a characteristic metallic sheen. Less often you can find black tiles on the shelves.

Patterns of material are varied. Ornate curls, geometrical ornaments, leaves, flowers are characteristic of the made foam tile. Drawing under marble represents divorces of different shades.

Metal and plastic varieties are characteristic patterns under the mat with mirror square inserts. Wooden tile has a simple relief in the form of rectangular and square channels.

Which one to choose?

In order not to doubt the choice of the best tile on the ceiling, you need to firmly determine the task of the tile, durability, practicality and design, take into account sound-absorbing capabilities and thermal conductivity.

- for a room with high humidity, you should choose a moisture-resistant tile;

- if it is planned to finish the suspended ceiling, you should purchase a tile with a relief;

- for the caisson ceiling, it is better to choose wooden perforated tiles with decorative grooves and figured cells;

- for the nursery, you can purchase a polystyrene foam extruded version with the possibility of painting when dirt appears;

- if the noise outside the walls is annoying, you should give preference to soundproof material (acoustic tile perfectly absorbs sound);

- if you need to visually enlarge the space, you can buy a tile with 3D effect for the ceiling decoration.

Choosing a finish for a classic or hinged ceiling, you should get acquainted with the products of specific brands, study the reviews of buyers and craftsmen about it - this will allow you to evaluate the subtleties of working with this material.

Subtleties of installation

Installing ceiling tiles is a relatively simple process that any chapter of the family can do. The main rules are accuracy and patience. This work does not stand in a hurry: every flaw will be visible and will require disguise.

To avoid common mistakes, it is worthwhile to carry out the ceiling finishing of the ceiling by all the rules, starting with the preparation of the foundation.

Preparation of the base

The tile adheres perfectly to concrete, drywall and wooden surfaces. However, the base is rarely perfectly clean and level. If the flaws are significant, then the porous and thin varieties will not be able to hide them.. In addition, it is worth bearing in mindThat glue seldom keeps well on a lime and surfaces with greasy stains. Before the preparation, all the furniture is taken out of the room and the lamp is removed.

The preparation process includes the alignment of the ceiling and the removal of visually noticeable bumps. In the presence of whitewash it is removed using a metal spatula, pre-closing the entrance to the room. After that, the surface is wiped with a damp cloth. If there are cracks, then they are smeared with a putty, align the waves of the base.

Primer

After the base has been leveled, it is treated with a deep penetration primer. This material has a penetrating power of 0.5 to 1 cm and is designed to strengthen the walls and give them a uniform structure.

Due to the viscosity and the formation of a special crystalline film on the surface, the primer improves the adhesion of the adhesive to the surface. With its help, the ceiling tile keeps on the ceiling much longer.

The ceiling is treated with primer twice - this will increase adhesion even in the places of problematic gluing of the base and tile (for example, with minor grease stains).The primer is applied using a construction roller with a long handle, which will allow you to make a larger sweep, speeding up the process of preparing the base.

For processing hard-to-reach places, for example, corners, protrusions, wall and ceiling joints, use a flat brush.. Its use eliminates excessive consumption of primer, the formation of splashes and drips on the walls. The second layer of primer is applied only after the first one has dried (from 12 hours to a day).

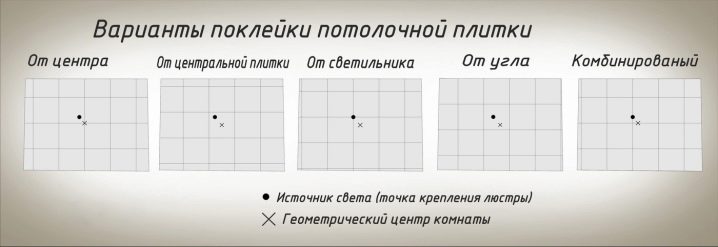

Markup. After the surface of the base is prepared for finishing, it is necessary to perform the marking. It is important to find the center of the future facing fabric - this is necessary so that the finish is identical in each side of the room. The lack of symmetry will visually distort the ceiling, which looks ugly. In addition, the markup will allow to calculate the amount of raw materials needed for lining. Experienced craftsmen, before starting work, perform a schematic sketch on which they paint the number of tiles and their location.

The center is the beginning of work - from him perform tile laying. Find it in three ways. To do this, you can use a regular thread and tape.In the first method, the threads are fixed to opposite corners diagonally, forming a crosshair, which will be the center (diagonal styling).

In the second method, the lengths of the walls are measured, their centers are found and the filaments are attached, forming a cross-hair (classical styling). These methods are especially relevant if the center of the crosshair coincides with the location of the central lamp.

The third method is carried out in the event that the location of the chandelier does not coincide with the center of the ceiling of the room. Then from the corners have to retreat the same distance as long as the crosshair does not coincide with the location of the center of the chandelier. After the threads are stretched, you can schematically draw them at the center with a pencil and ruler, setting the direction of the tile.

Piling

The first nuance when laying the ceiling tile is the center design.

This can be done in three ways:

- gluing one tile in the center with a hole cut in the middle to fix the chandelier;

- aligning two tiles and cutting a hole in the middle of their seam;

- from four parts, combining them together the angle along the marked lines.

The first option is impractical and in the case of replacing the tile will require the removal of the chandelier.The second and third options in the case of replacing the tiles will allow you to carefully remove the fragments, replacing them with new ones (for repair it is worth buying a few more tiles). The quality of the entire work will depend on how carefully the first tiles are interconnected..

If at the same time there is at least a small gap, then there will be gaps in the finishing canvas, which will eventually lead to the loss of the tile from the finished canvas.

After the first fragment is glued, others are glued to it from all sides. If diagonal laying is planned, the fragments are glued, moving in a spiral, which will reduce the number of gaps between the fragments to a minimum. If the installation is done in a direct way, then it is preferable to press the tiles on both sides of the walls - so it does not budge and will be tightly pressed by neighboring elements.

As an adhesive for wooden, plastic and metal varieties, it is better to use the composition of liquid nails. - this glue will fix such materials tightly.

For foam tiles, you can use mastic or special glue for ceiling tiles. One caveat should be considered: the glue color must be super white, otherwise it may be visible through thin plates. Such a composition can be covered with seams, if after pasting gaps between the tiles will be noticeable.

For PVC tiles, you should not take "Titan" in plastic buckets and liquid nails - these compounds have a dirty beige tint, the gluing places of which will be visible through the tile. It is necessary to take into account the fact that "Titan" eats tiles, so there is no question of any compatibility of the corners. It is better to use a clear adhesive of this brand for repair, the packaging of which is a plastic bottle.

How to glue the ceiling tiles, see the following video.

What can be painted?

Staining ceiling tiles made of polystyrene foam is possible prior to laying and after it. In the first case, this will allow to paint individual elements on a white surface, and in the second case, to roll the finished finishing sheet with a fur roller.

Painting is carried out in two types of paints: water-based and acrylic. They are distinguished by sufficient density, durability, moderate degree of gloss and moisture resistance.These coloring materials are resistant to wet cleaning of the surface and the effects of microorganisms. The wooden, metal and plastic surface of the tile is not painted.

You can not use dyes from cans - they eat up the material, causing it to shrink.

Care Tips

The cause of contamination of the cladding can be gaps between the tiles, high humidity, dust, tobacco smoke and grease falling on the surface.

To ceiling tiles longer preserve the attractiveness of the appearance, you can arm yourself with simple recommendations:

- Not every type of tile can be washed: a porous and matte surface will suffer from wet cleaning. This tile can only paint over.

- If the pollution is small, you can try to remove it with a regular office eraser.

- Chemicals are unacceptable: they destroy the structure of the cladding material.

- In the absence of stains and heavy dirt, you can vacuum the surface no more than once a month at low power.

- The foam tile can be cleaned with a special soft brush for dry cleaning - this way the surface can be removed from dust.

- It is possible to wash thick tiles using a small amount of dishwashing liquid, a liquid laundry detergent and even shampoo.

- Wet cleaning is extremely rare, strongly squeezing a cloth or sponge.

- To get rid of soot, you can buy a sponge with a special impregnation.

- To get rid of yellowness, use salted water.

Examples in the interior

Evaluate the attractiveness of the ceiling ceiling tiles will help examples of photo galleries.

Polystyrene tiles with imitation of elite wood look expensive and stylish.

Partial ceiling tiles with a glossy surface and gold are perfectly combined with a wooden plinth.

The design of a seamless tile with a mirror surface looks unusual and elegant.

Tile with a gold-plated pattern successfully allows you to decorate it with an original lamp with gold.

The combination of two types of tiles allows you to zone the room space.

The pattern of lining in the center of the dining room allows you to select the dining space.

Accenting the wall in the bedroom with the patchwork technique looks colorful, stylish and unusual.

Seamless tile in white with a pattern to match the wallpaper makes the interior special.

The use of a metallic finish with a rich touch is appropriate in the bathroom.

Especially beautiful is the ceiling tile with a baseboard of a similar relief.

Selection of the wall near the dining area looks pretty nice.