The ceiling of plastic panels: the advantages and disadvantages

Polyvinyl chloride panel (PVC or plastic panel) appeared on the building materials market not so long ago, but in a short period of time won positive reviews from consumers, in particular, those who prefer to engage in repair work personally, without resorting to the services of specialists. Finishing this material looks just fine.

Special features

The demand for this material lies in several factors:

- favorable technical and operational properties;

- wide assortment (different types of plastic lining, variety of colors, quality, texture, price);

- Extremely simple and affordable installation system of plastic sheets on the ceiling.

Due to the fact that a wide range of PVC panels is able to please every consumer, this type of finishing work is recognized as universal.The presented types of plastic lining can be divided into several categories: polyvinyl chloride panel in tile format, wall paneling, polyvinyl chloride sheet. In these categories, plastic panels differ in size, cost, level of rigidity, weight. Other characteristics, for example, the size of the panel, depends on the category in which it is included.

Standard parameters for the thickness of plastic sheets are located in the range from one to half a centimeter. These options are extremely important if you plan to purchase moldings. Moldings - decorative strips, used as decoration.

Plastic ceiling lining differs from wall lining more light weight. Due to the fact that the strength for finishing the ceiling is not a paramount feature, the manufacturer highlights the task of maximally lightening the weight of cladding material and creating various variations in shades and texture. In order to save your budget from unforeseen expenses, you need to pick up the material in advance, taking into account the area of the roomso that after the completion of the finishing work, you find a minimum of the remaining material.

Polyvinyl chloride sheets are extremely easy to clean. They can be used for finishing work in any household premises, for example, in the bathroom, shower, in the kitchen, in the bathroom

In order for plastic sheets not to lose their visual appeal, it is recommended to regularly clean. It requires only a damp soft cloth or sponge and a soap solution that does not contain abrasive particles.

Advantages and disadvantages

Consider the positive and negative aspects of the use of plastic panels as a ceiling covering. So, the benefits include:

- Plastic resistant to the harmful effects of moisture. If you live in a high-rise building and your neighbors flooded you from above, do not be in a hurry to get upset. In this case, in the areas where water enters the PVC, the panels are carefully dismantled. They need to be postponed in order for them to dry out. Then you can install them in the original place.

- High quality plastic panels serve you for several decades. And in order to change the damaged element, it is not necessary to dismantle the entire ceiling. It is enough to change the necessary areas.

- Pvc ceiling does not require special care methods. It is recommended periodically using a soft cloth soaked in soapy water, to clean the panel from dirt or dust. The only thing is prohibited to apply solutions that contain abrasive particles or aggressive alkali and acid.

- In order to fix the plastic panels on the ceiling, need to build a frame. As a result, he and plastic panels form an empty space. This is a great place to hide the insulation, gasket from electrical and sound wiring.

- PVC sheets often used as a ceiling lining. This method does not require large financial costs, it will save your time and effort.

- Being a versatile material, plastic sheets will look equally good in the living room, kitchen, bedroom, bathroom and even on the balcony.

- Plastic Ceiling Suspended Ceiling extremely convenient for the construction of the lighting system, which will be located on all areas of the dwelling or in the places necessary for you.

- Preservation of its characteristics with sharp temperature jumps.

- Another advantage of plastic plating is easy installation. For installation it is not required to prepare or process the surface of the ceiling - there is simply no need for this.

Disadvantages of using polyvinyl chloride sheets for the ceiling:

- Despite the high resistance of plastic sheeting to high temperatures (up to four hundred degrees), like all plastic, such a ceiling has a high risk of fire. It is worth noting that when burning plastic emits toxic gases. In this regard, it is recommended to reduce the weight of the suspended and built-in luminaire in the ceiling structure and not to mount the plastic panel ceiling in rooms with an open source of fire.

- The plastic panel is made of facing panel, in other words, this is ordinary plastic. Therefore, it is not able to counteract mechanical effects, for example, a hammer blow. Cracks appear on the sheet, and subsequent operation becomes impossible.

- When planning the installation of plastic sheets as a ceiling surface It is recommended to check if direct sunlight will fall on it. The fact is that with the constant exposure of the sun, PVC sheets begin to quickly burn out and soon become unpleasant yellow shades. And when choosing color panels in a short period of time they fade.

- Many do not prefer to choose plastic sheeting as a ceiling finishing surface, since, in their opinion, living space takes on the form of office. But as you know, this is a matter of taste.

Dimensions

The standard thickness of the plastic panel for the ceiling is 8-10 mm. This parameter is fundamental for the production of molding, selected depending on the size of the panels. On sale you will come across plastic panels with a thickness and 5 millimeters, and more than 12 millimeters. But in this case, the selection of a suitable molding will be extremely difficult.

The standard length of a polyvinyl chloride panel is:

- lining - width is 10 centimeters, length is 3 meters;

- wide PVC panel - width 20 centimeters, length also 4 meters.

The width of the PVC panels are divided:

- Lining - 10 centimeters wide.They are divided into two types: the standard “European” with a large lock and the “polka” with a small lock.

- Wall paneling - 15 centimeters wide. It differs from other panels by the presence of a double profile construction.

Often used plastic panel - the sheet has a standard width of 80 to 200 centimeters, length varies from 150 to 400 centimeters. Thick sheets from 5 to 30 millimeters, depending on the preferences of the consumer and the brand.

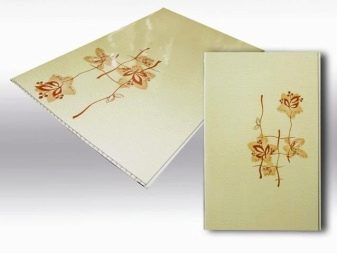

Design

The most popular color solutions in the range of plastic plating are: neutral white or light yellowish, bluish and pink shades. These kinds of colors are used due to the fact that the ceiling visually expands the space, does not create a feeling of pressure and is easily combined with any interiors. When buying a plastic cladding material, consider the prevailing colors selected in the interior. Depending on them, you can choose any color solutions, preferably avoiding dark and bright colors.

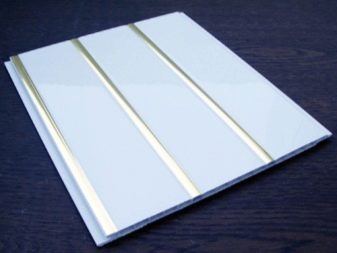

The most simple and optimal option for the plastic surface of the ceiling are PVC panels located on the same level around the perimeter of the room in the same shade. When using seamless plastic sheets, you can effortlessly achieve a perfect and even ceiling surface.

Plastic sheet is perfectly cut, so when installing a frame structure for suspended ceilings, it is also easy to build in lighting devices.

AT kitchen space It will originally use narrow PVC sheets with a wooden structure that look like a wall panel. Such panels add to the room an atmosphere of comfort and warmth. And the installation of sheets will be easier than when installing from a natural counterpart. Often plastic panels are made with a visible seam. Such panels can be advantageously applied in interiors.

For example, a longitudinal strip will allow to lengthen, stretch the space, while the transverse will expand it. Such techniques can visually change the dimensions of the dwelling.

It is acceptable to use a combination with alternating colors. The ceiling from white and beige seamless strip, which width is 250 millimeters, will look original in the interior where the kitchen set of natural wood is involved.The combination of multi-colored PVC sheets will add a zest to the decor of your room and make you forget about the use of one of the cheapest building materials. Visually increase the height of the room will allow sheets in bluish and greenish shades. Such color solutions contribute to creating a calm and peaceful atmosphere.

To make a panel of such material in the corridor or hallway is not at all difficult. To do this, you can choose a 3D, mirror or slatted version with a special step.

What to choose?

For a small dwelling, a plastic panel in the lining format will be the best choice. Horizontal lines will pull out the floor space. As for the larger room, it is recommended to purchase a polyvinyl chloride sheet. The thickness of the plastic panel is standard and usually does not exceed ten millimeters. So, what should be focused on:

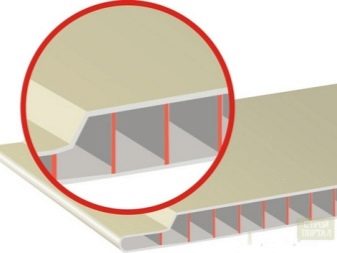

- The quality stiffener on the front side of the PVC panel in no way shines through. Take note that, depending on the number of edges, the strength of the panel depends. The more of them - the longer the life of the panel.

- Inspect the appearance of the plastic panel - you need to have a flat surface. The presence of external defects can be a sign of damage not only to the aesthetic appearance of the panel, but also to its quality and strength.

- Mounting and mounting shelves are flexible and ductile and should not crack when bent.

- It is recommended that the store be gently pressed on the plastic panel. In case of a poor-quality copy, the panel will crack or a dent will form on the surface, therefore, it is worth refusing to purchase it.

- It is advisable to check the material for docking with each other. To do this, put together a pair of plastic panels. Quality elements fit smoothly, without gaps.

- View the appearance of all plastic panels offered to you. In all packages the panels should be of the same texture, one tone and shade. There are cases in which plastic sheets purchased in different batches have insignificant differences in color shade.

Despite the fact that the purchase of PVC panels is based on the personal preference of the person who has decided to repair, there is a set of rules with certain recommendations that will help to achieve the desired result. Here he is:

- In order for the ceiling to visually look taller than it really is, give preference plastic sheets of light shades. Sheets of dark color potentially “eat up” the height of the room and the audience has a feeling of pressure.

- Glossy plastic panels have one unique ability - to reflect the space inside. This creates the effect of the depth of the room. Due to this, the ceiling surface looks farther, thereby visually pulling the room upwards.

- In order that the space inside the room does not turn out unpleasantly motley, It is recommended to use no more than four shades. At the same time, black and white are basic colors and are not absorbed as additional elements of the color palette. That is why household appliances are often painted white or black.

- Highlighted seams on plastic sheets emphasize the unnatural appearance of the product. For people who prefer naturalness, it is recommended to give preference to a seamless glossy sheet in white shades with the required width. They will draw less attention to the ceiling surface.

Tips and tricks

The PVC panel, when aligned to the desired size, is cut and drilled on the front side, turned up. For trimming, a hacksaw, a hand saw and a construction knife are used. It is recommended to wear specialized glasses to protect your eyes.

When buying, pay attention to the composition. Manufacturers who care about the health of the consumer, add to the composition of the polyvinyl chloride sheet lead. It performs the activity of the stabilizing component. If a fire occurs, under the action of high temperature stress plastic sheets will not emit harmful, toxic and toxic substances.

It is recommended to use a hard plastic shell. It is less prone to ignition and has high sound insulation characteristics.

When planning the installation of polyvinyl chloride panels in a room with high humidity, it is recommended to purchase a metal crate. When white PVC sheets are mounted, small gaps often occur. To solve this problem you will help liquid PVC. Lubricate the crevices and allow the composition to dry.

There are several basic ways of attaching PVC material to the ceiling. You have the opportunity to choose the one that is right for you:

- In the crate. The most common way. In this situation, the panel is fixed on the frame of wood or metal. A stapler or nails are used to fasten to the wall or ceiling. A great way to mask the entire uneven surface. Installation does not take much time and effort.

- On glue. In this case, the plastic cladding material is fixed on the ceiling previously cleaned from previous materials using liquid nails. It is allowed to use dowels for reliable and durable fastening. It is recommended to make sure that it is suitable for plastic surfaces before purchasing an adhesive. This is one of the most energy-intensive ways, but it is extremely practical, especially for rooms with a small area.

- Assembly Klyaymer. Kleimer - a special element for concealed fasteners. This method involves fixing plastic panels to the crate by “fastening” with plastic slats. This is one of the fastest ways to install.When the need arises, such a structure is disassembled quickly and easily. It is practical to use this method of fasteners in the bathroom with a small area.

How to fix plastic panels to the ceiling is shown in the video.

Care

After installing the plastic sheathing, it will require systematic care. The process of cleaning PVC panels is extremely simple and consists of several recommendations that will make the plastic surface look like new:

- When installing plastic cladding material in the kitchen, fat deposits can accumulate in the joints. In this case, it is recommended to apply liquid dishwashing gel. Do not use scouring powder, it has a habit of leaving microscratches.

- For cleaning PVC material suitable soft foam sponge and flannel cloth. The file should be handled carefully.

- Do not use detergents containing solvents, abrasive particles, aggressive alkali or acid. Such compositions will quickly invalidate the sewn material.

- The yellowed panels are perfectly washed off with dissolved white in proportion to two tablespoons per five liters of water.

Beautiful examples

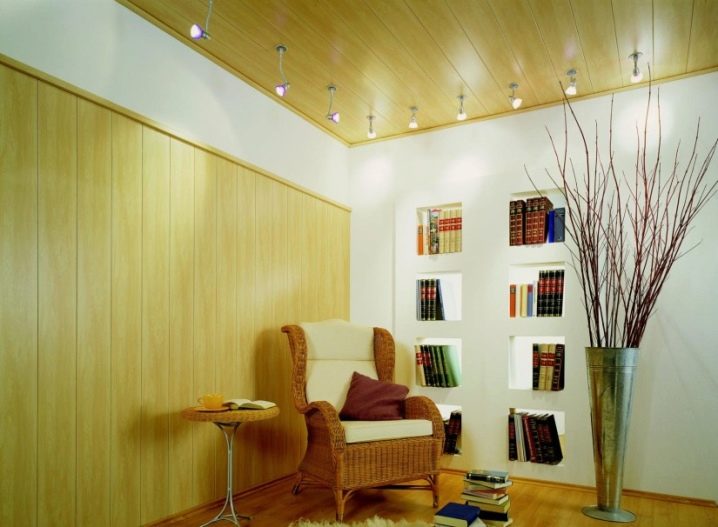

For this interior were used seamless glossy PVC panels. Sheathed ceiling looks like a single flat surface. And the glossy reflective surface of the ceiling creates the illusion of depth.

As we see, the use of plastic panels under the wood structure adds to the kitchen interior atmosphere of coziness and warmth. And the installed crossbeams gave the ceiling a natural lining look.

Universal option for any type of room - white plastic panels in the format of strips with visible seams. Longitudinal lines will pull the room in length, and a light shade due to the light will increase the space.