Warming the ceiling: ways and recommendations

Warming the ceiling can not be called a complex and time-consuming process. Thanks to this work, it is possible to significantly reduce heat loss through the ceiling. To make the room warmer, you can use different types of heaters, each of which has its own strengths and weaknesses.

Today we will talk about how to insulate the ceiling, as well as read the recommendations of experts.

Special features

Tangible heat loss, as well as cold air emanating from the ceiling, are the result of improperly installed or poor quality insulation. Heat loss through such overlap can reach up to 20%, since warm air rises and barriers are needed that will not allow it to leave the room.

It is recommended to warm the ceiling during the construction phase. However, there are cases when the owners for some reason do not produce such work in the specified period.In addition, there are not rare situations when the old thermal insulation becomes unusable in an already constructed dwelling. And in such conditions it will be possible to put a heater, but the work will be more difficult. At the moment there are several methods for thermal insulation of the ceiling.

Many consumers are wondering why it is necessary to insulate the ceiling and whether such works can be neglected. To find out the answer to these questions, you should familiarize yourself with the main functions that, in this case, the heater performs:

- High-quality insulation have excellent sound insulation properties. Thanks to such elements, silence will always be preserved in an apartment or a private house, even if there is rain and wind outside the window.

- Thanks to the installed insulating layer, the room will be warm in winter, because the heated air, going up, will encounter an obstacle and come down again.

- Useful ceiling insulation will be in hot seasons. It will prevent the penetration into the room of hot air, so it will remain comfortable cool.

It is also worth noting the situations in which insulation of the ceiling is necessary:

- Insulation of the ceiling should be addressed if you have just started building a house. At this moment the ceiling consists of ordinary wooden beams. Then you can lay a heater between them and "sew" it.

- Also, you can proceed to this work, if the owners have already begun to occupy the house and the ceiling has long been ready. It is necessary that the living room was not cold in the fall and winter.

- Ceiling insulation is simply necessary if no one lives on the top floor of the house. As a rule, it is always cooler in such rooms. In such situations, heated areas lose their heat in favor of unheated.

You should not think that it is possible to be engaged in heat insulation of a ceiling only at arrangement of the private house. Such work is quite acceptable to carry out in apartment buildings.

In such dwellings, all actions can be performed only inside, and the lofts and roofs of the residents are not allowed to be independently repaired.

Currently, various materials are used for insulating ceilings. Each of them has its own operational characteristics, on the basis of which it is necessary to choose a suitable option for certain conditions.

Insulation Requirements

Ceiling insulation must meet a number of requirements:

- It must be environmentally friendly and safe. Otherwise you risk harm to the health of the household.

- Insulation should be fireproof.

- Due to the heat-insulating layer, heat loss should be reduced, not steam circulation occurring in the house / apartment.

- Insulation should not get moisture.

Types of insulation: the pros and cons

There are several types of insulation materials. We will get to know them better and consider what advantages and disadvantages are characteristic of them.

Mineral wool

This is one of the most popular and sought-after heaters. This material has a base of mineral or fiberglass.

There are several types of mineral wool:

- Stone. This mineral wool is produced from melts of igneous rocks.

- Slag. This insulating material is made from the molten blast furnace slag.

- Glass. This mineral wool is created from a glass melt.

In the composition of stone wool there are ingredients such as gabbro or diabase, as well as blast furnace slag and the mixture. Of the mineral ingredients in the composition of the basalt insulation there are clay, dolomite, limestone. These components are necessary for the material to be more fluid.In the role of a binding element in this composition are formaldehydes in small quantities (2-10%).

For slag fiber characteristic fibrous structure. This insulation is made from the waste of the metallurgical industry in the smelting of iron in blast furnaces. Slag fibers differ in small thickness and length.

In the process of creating glass wool, elements such as sand, dolomite, soda, lime, borax and glass blasts are used.

Mineral wool may have different markings:

- P-75. This kind of wool has a density of 75 kg / cu. This material is used to isolate horizontal non-external planes. This may be the attic or roof. In addition, the mineral wool P-75 is used for insulation of pipelines of heat networks, as well as oil and gas pipelines.

- P-125. Mineral wool under this marking has a density of 125 kg / cc. It is used for warming non-external foundations in any position. Material marked P-125 is also used to insulate the floor and ceiling.

- PZH-175. This type of wool is treated with reinforced concrete or profiled floor slabs.

- PPG-200. Wadding PPG-200 is used in the same way as PZH-175, but is more fire resistant.

Minvat has many positive qualities:

- It is distinguished by low thermal conductivity. Because of this, mineral wool is an effective insulation.

- Such material is recognized as fireproof.

- She is not afraid of temperature drops. Under conditions of overheating and overcooling, mineral wool is not deformed and does not lose its shape.

- For mineral wool is characterized by chemical and biological resistance.

- This insulation is characterized by high vapor permeability, so it is "breathable."

- Installation of mineral wool is quite simple and quick. With it the home master who does not have a wide experience in such works will easily cope.

Despite its popularity, mineral wool has some drawbacks:

- This material requires treatment with special water repellents to reduce water absorption. Absorbing moisture, mineral wool loses its insulating properties.

- This insulation can not be called easy. Because of this, the cost of its delivery increases significantly.

Ecowool

This is another popular thermal insulation material that is produced from waste paper and other waste from the paper industry. It is a crumbly mass of gray.

As a rule, ecowool is impregnated with special compounds, such as flame retardants and antiseptics. These components are necessary so that the insulation was not afraid of insects and rodents.

Let's get acquainted with the pluses characteristic for ecowool:

- It is environmentally friendly and safe for health.

- Ecowool is a “breathing” material that is perfectly breathable. Indoors, warmed with such material, comfortable even in hot summer.

- Ecowool does not rot and does not become covered with mold. Of course, such a heater will not rot, if not to saturate it with moisture. Otherwise, ecowool can be seriously affected.

- The similar heater differs in durability. Even after many years, he does not lose his useful qualities.

- Ecowool can be supplemented or compacted.

- It is not combustible and will easily damp out in case of fire.

- This insulation is easy to use, especially when it comes to warming the horizontal plane.

- Many people choose eco-wool insulation, as it is homogeneous - it does not have seams or joints.

The main disadvantage of this insulation is that the dry fill closes and undergoes sedimentation over time. Because of this, it must be laid on the base with a thick layer.

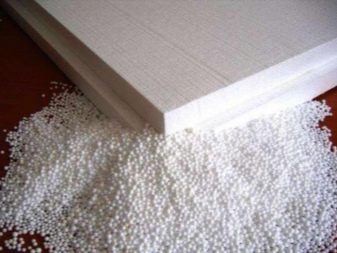

Styrofoam

This type of insulation material is used everywhere. It is inexpensive and is installed quite simply. Its structure is a special foamed mass in which the bulk of the volume falls on the gas. Because of this feature, the density of the foam is quite low.

For insulation ceiling you can use foam plates of different density. However, it should be borne in mind that not very dense materials require additional protective measures, because they can not boast of sufficient strength characteristics. As a rule, loose materials are installed in a frame way.

Consider the positive side of the foam as insulation:

- This insulation is not afraid of moisture and dampness. In addition, the foam does not absorb it almost.

- Differs in quite good heat-insulating characteristics.

- The surface of this material is not subject to the formation of fungus and mold.

- This insulation is easily cut and easy to install.

- It has a small weight.

- Polyfoam is inexpensive.

- It has a long service life.

- Differs in the fine soundproofing characteristics.

- Does not need additional waterproofing.

Polyfoam is not perfect insulation, it has its drawbacks, which you should know if you decide to refer to this material:

- This insulation has limited mechanical strength. After laying it needs additional protection from external damage.

- Polyfoam is not a breathable raw material. He practically does not let air through him.

- This material quickly comes into disrepair under the influence of nitrokrasok and other paint and varnish coatings with such a base.

Penoplex

This insulating material was invented about 70 years ago. However, extruded polystyrene has spread only in the last 10 years. Today it is used for warming roofs, foundations and floors.

Warming the ceiling penoplex has its pros and cons. First you should get acquainted with its strengths:

- Penoplex differs in low vapor permeability. Due to this quality, this material does not absorb moisture.

- Penoplex also features low thermal conductivity.

- It easily withstands significant loads, which indicates its compressive strength.

- Penoplex boasts a long service life (up to 40 years).

- Installation of such insulation is simple and affordable.

- Penoplex is relatively inexpensive.

The disadvantages of penoplex include:

- fire hazard;

- susceptibility to attacks of rodents and various parasites;

- weak adhesion with various bases due to excessive density.

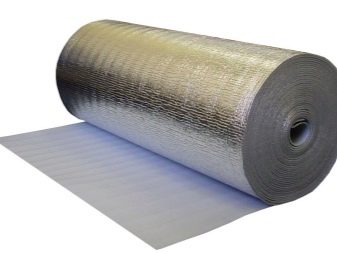

Penofol

Another popular insulation, covered with foil. As a rule, it is used indoors and reflects heat.

Sheets of this insulation is recommended to mount the butt joint, since so they form a more efficient single web without gaps and gaps. The seams in this case should be glued with a special metal tape.

Let's get acquainted with the benefits of penofol:

- It has a small thickness, but at the same time provides high-quality thermal insulation of the living space.

- Easy to install. For such works do not require special and expensive tools.

- Penofol does not crumble and does not break.

- It is environmentally friendly and safe material.

- Waterproof.

- Fireproof.

- It has excellent sound and waterproofing properties.

- It has a democratic value.

The main disadvantage of penofol is its soft structure. You can easily press on it, after which he will definitely bend over. For this reason, finishing this layer with plaster or wallpaper will be impossible.

Perlite

Perlite or perlite sand is a popular material possessing the best properties of all effective heaters. It is very persistent, inert and light. Perlite raw materials are distinguished by the fact that its composition contains from 2% to 5% of bound water. This material is inert due to its chemical nature.

The main properties of perlite include:

- high thermal conductivity;

- sound absorption;

- water absorption.

And now it is worth considering in more detail what advantages perlite sand has:

- It is a non-combustible material.

- Differs in the increased zvuko-, warm and waterproofing qualities.

- It is biologically resistant. Not conducive to the reproduction of dangerous bacteria, parasites and rodents.

- It is eco-friendly and durable.

If you decide to use perlite, then you should know about its weaknesses:

- This insulation is not found in all stores;

- is not cheap;

- before direct use, perlite sand must be thoroughly moistened, as it is quite dusty;

- does not participate in ion exchange, since it is characterized by a positive electric charge.

Sawdust

Sawdust is the cheapest and most affordable insulation material. They are used for both residential and for farm buildings.

Sawdust is waste that remains during wood processing. They are normal chips or fine dust. Previously, such materials were widely used for warming dwellings, but with the development of high technology, they faded into the background and became considered obsolete.

But do not think that sawdust is no longer used for the insulation of buildings, they are still used for these purposes. This is due to the effectiveness of sawdust, as well as their incomparable durability.

Sawdust has a number of positive qualities for which modern consumers choose them:

- They are inexpensive. Afford every heater from sawdust will be able to every owner.

- This material is environmentally friendly and safe for the health of households.

- Sawdust has excellent thermal insulation properties.They keep warm well. According to this quality, they can be compared to mineral wool.

As for the shortcomings of sawdust, these include:

- mild flammability;

- insects or rodents can get in sawdust.

In addition to the sawdust itself, other materials can be used for home insulation, which are produced based on them:

- arbolit;

- opilkobeton;

- sawdust granules;

- blocks.

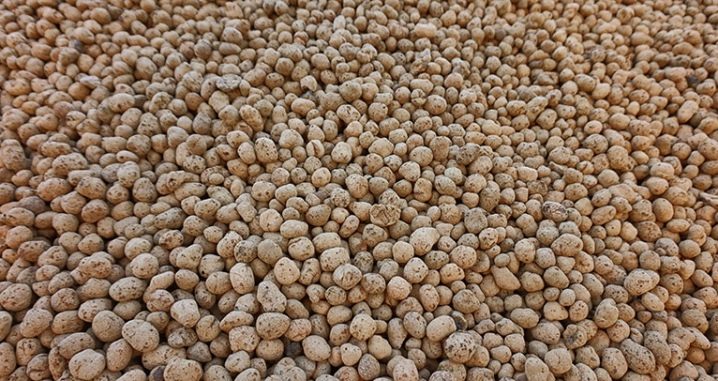

Expanded clay

It is possible to warm the dwelling not only cheap sawdust, but also expanded clay. This material enjoys an enviable popularity in our country, as it is inexpensive and has excellent performance characteristics.

Expanded clay consists of the smallest granules having a small mass. In the granules there are pores that make these elements as light as possible.

Let's get acquainted with the positive qualities of this insulating material:

- Expanded clay is inexpensive and is available material - it does not have long to look for in different outlets.

- A characteristic feature of expanded clay is high thermal conductivity.

- This material is lightweight, so it is very easy to work with it, it does not give significant loads on the base.

- The warming layer consisting of expanded clay can serve for a long time without any problems (up to 50 years).

- Expanded clay - an environmentally friendly material that does not emit hazardous substances.

This material has its own disadvantages:

- Using expanded clay, it is very difficult to achieve complete sound insulation of the room. To do this, you will have to form a half-meter insulation layer.

- This heater will require additional investment from the owners to protect against moisture.

Because of this lack of use of claydite to insulate old and damp buildings is not recommended.

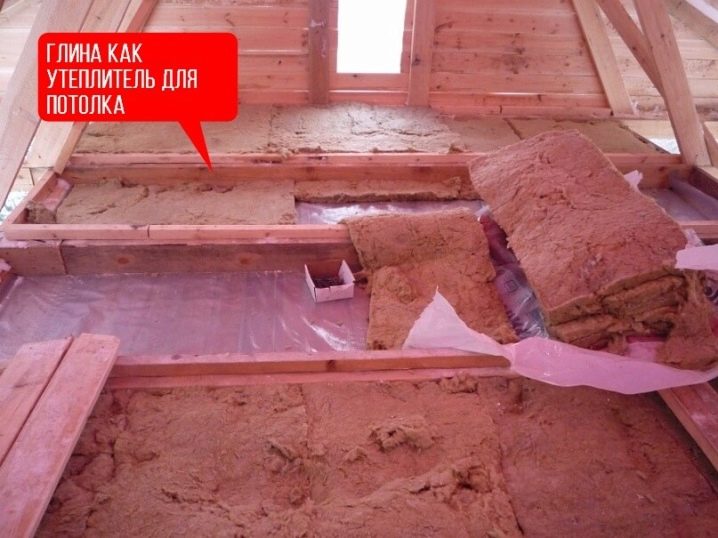

Clay

Warm ceiling can be clay. Such material is inexpensive and environmentally friendly. It perfectly protects the space from heat leakage. In addition, with a similar insulation the room will remain cool if the weather is hot in the yard.

Clay is well diluted with water, and after drying it becomes very hard and retains heat well. Most often, this method of thermal insulation is addressed when processing rooms with a large area.

Let us see what advantages this eco-friendly heater has:

- It is inexpensive, and therefore has no competitors among analogues.

- Is a fireproof material - does not burn, does not sustain combustion.

- In such a heater do not live insects or mice.

- The solution for insulation of the ceiling is diluted with sufficiently lightweight fillers, which significantly reduces the load on the ceiling.

- The clay does not contain harmful impurities.

- This material is easy to work with. For this it is not necessary to hire professionals.

- The dried mixture can be used again. To do this, you just need to wet it. Thanks to this feature, a large amount of waste can be avoided after all the work has been completed.

- After adding water, the clay becomes very plastic and easily penetrates into any voids present on the substrate.

- After complete evaporation of moisture, the clay becomes hard. For this reason, lay the floor for walking on the attic floor is not necessary.

However, at present, clay has been supplanted by more modern thermal insulation materials.

There are several good reasons for this:

- Warming clay is not considered the most effective. As a rule, this material is used only as an addition to the main insulation.

- To correctly prepare the clay solution, you need to carefully maintain all the required proportions. Otherwise, the heat-insulating layer may simply collapse or will not perform its main functions.

- The finished clay mixtures are heavy, so they should be laid only on stable floors, which can withstand significant loads.

Mounting methods

Installation of insulation can be done independently. This work is done in two ways. Let us consider in more detail each of them.

From inside the room

Experts do not recommend insulating the ceiling in the inner part of the dwelling. During such work, you will not only reduce its height, it can also lead to the ingress of the insulating material itself and its fumes into the room. In addition, in such cases, a fungus and mold may appear on the thermal insulation material.

If you have no choice, then you should consider some limitations:

- do not use mineral wool to insulate the ceiling indoors;

- leave a small gap between the insulation and the ceiling finish.

To insulate the ceiling in the interior of the room is perfect penoplex or penofol.

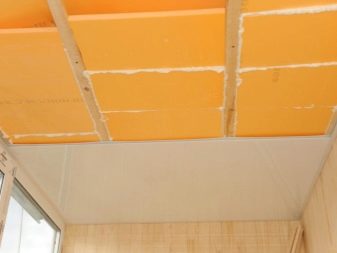

According to experts, it is quite easy to work with penoplex.First, you will need to nail the crate, which will be further attached to the drywall sheet. Pay attention to the height of the timber obreshetki. It should be 2-3 centimeters more than the thickness of the insulation.

Between the slats should remain a step equal to the width of the insulation (approximately 1-2 mm). After that, between the crate you need to make the laying of a warming coating. It should enter the right places with a little effort. To keep insulation warm on the ceiling, it should be attached using dowels..

At the end of the work, sheets of drywall are attached to the crate. Thus, it turns out a kind of suspended ceiling. If you do not want to install conventional drywall, then you can turn to the installation of the tension structure.

To install penofol also need to prepare the frame. Next, you will need to put a heater on it (foil side inside the room). The warming material can be nailed to the frame structure with nails. Gaps for ventilation should be left on both sides.therefore, you will need to install the second crate from above - plasterboard sheets will be attached to it.In this case, you can also refer to the stretch ceiling.

Outside

Warming the ceiling from the outside of the room involves laying insulation not from below, but from above the ceiling (or into the voids, if any). In this case, the technology of laying largely depends on the base material.

For example, for wooden floors it is better to use lightweight bulk options, and for concrete slabs, more impressive insulators with greater weight will do.

Let us consider in more detail how to properly lay the insulation outside using the example of a mineral wool.

For wooden floors

Between the beams need to lay the material vapor barrier. The film must be laid with an overlap, and then glue the joints with duct tape.

- Then between the beams it is necessary to put mineral wool 100-250 mm thick (here it is necessary to calculate the heat loss).

- Insulation must enter the base with effort, so it must be cut with a margin.

- Further, the insulation is closed with a finishing material.

For concrete

In this case, the base must be thoroughly processed and leveled, removing all bevels and potholes.

- Then you need to mount a vapor barrier film.

- It will be filing mhvaty.

- Next comes the fixing of the finishing material (cardboard, plywood, wood).

Tips for choosing

Choose a heater under the cold roof should be based on several criteria:

- Type of room. Different insulation conditions are suitable for different conditions. For example, for the loggia and the balcony more suitable minvat, penoplex, izolon or foam, and for the attic or attic - and even basalt insulation or polyurethane foam. For spaces with a high level of humidity, moisture-resistant insulation should be chosen, otherwise they will quickly become useless.

- Base material. For wooden floors should buy lighter insulation. For the concrete base, you can buy materials that give large loads.

- Environmental friendliness. Experts recommend to buy only environmentally friendly and safe types of insulation.

- Fire safety. Pick up non-flammable insulation that does not support combustion.

- Manufacturer. Contact only well-known manufacturers, producing high-quality and durable products.

Useful recommendations

If you decide to install a ceiling heater in your house, then you should heed the advice of experts:

- Do not neglect the installation of waterproofing when laying insulation material. This will avoid the formation of condensate on the base, which can then get to the insulation.

- If you need to insulate the first floors in a low-rise building of a private type, then for this it is worth using penoplex.

- It is possible to warm the ceiling on the top floor only from the inside of the dwelling, despite the fact that this method is not recommended by professionals.

- If you decide to put sawdust for insulation, then you will need to check whether they are dry or not. To do this, go through them before laying. Dry material will bend and crunch.

- The attic, which is insulated from all sides, and also equipped with heating, is not an attic, but an attic. Allowable insulation materials for such areas are listed above.

- If you are installing penofol, then you should not use fasteners that need to be nailed, this method may adversely affect the insulating properties of this material. It is better to buy insulation with adhesive base.

- After laying the insulation material (especially if it is tiled) on the base, you should always seal all the gaps and joints. Most often for this use mounting foam.

- If you work with mineral wool, then you definitely need to use protective equipment - gloves and a respirator. After fixation, this material will be safe, but in the process of laying and cutting in the air can be tiny particles that will irritate the mucous membranes, as well as cause itching on the skin.

- It is necessary to fix insulation as reliably and efficiently as possible. To do this, use a variety of fasteners, slats and twine.

- Insulation in the form of plates can be mounted on the ceiling with glue. For this, it is permissible to use a reliable cement-based compound. Home masters leave good reviews about this method of installation, as it seems to them easier and faster.

See how to insulate the ceiling in the next video.