Ground siding with imitation bricks: the pros and cons

Each owner tries to make his home not only comfortable and convenient for living, but also attractive in appearance. Therefore, materials that are not only of high quality and have the necessary properties, but also help to realize the design ideas of the consumer, are chosen for finishing work. Brick siding with brick imitation is used for house trimming by people with good taste who plan to make their home look neat and presentable.

What it is?

Brick panels are often used by residents of Canada and the United States to trim their homes. Later they became widespread in Russia, however, they are called “ground siding”, because they are used for the most part in the decoration of the base. The reason for this is that the price of the materials differed from the cost of ordinary vinyl panels, and the main part of the facade of the house was sheathed with ordinary siding.

Despite the fact that the pricing policy in this area has changed a long time ago, the name is now used in its previous form. In this case, more often the owners sheathe their homes completely basement siding.

The choice of materials on the modern market is very wide, which forces manufacturers to work on expanding the range. Specialists are constantly changing both the look and the texture of the panels, developing new models, so if you want to make your home as individual as possible, this is not so difficult to achieve. According to the above, this type of siding can be used in several ways. In the first place - it is facing the basement. The panels are thick enough to withstand enduring external influences and damage due to external factors, which is very important in winter, as snow pressure, low temperatures and other factors seriously increase the load on the object.

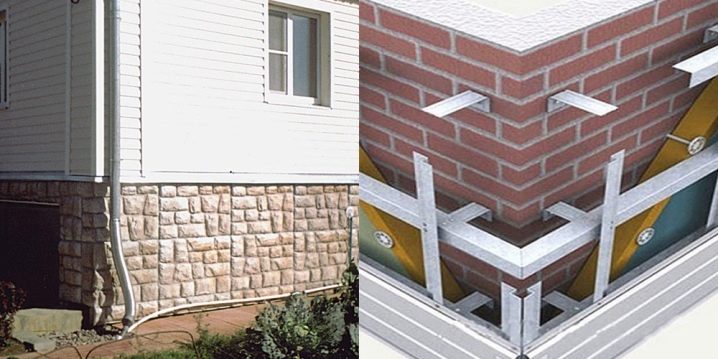

In addition, facing "under the brick" may be partial. With the right idea, a combination of simple and basement siding looks advantageous, which gives the structure an original and unique appearance.As well as the material can sheathe the entire building, completely changing its visual perception. With a full finish, a wooden house can easily be turned into a brick version, giving it style and presentability.

Advantages and disadvantages

All finishing materials have their advantages and disadvantages. Ground siding is no exception. In order to understand whether the owners are ready to use this material in their work, it is necessary to study its basic properties, as well as pros and cons. Siding, imitating brick, has many advantages. Among them it is necessary to highlight the affordable cost of materials, which plays an important role for the consumer. The panels look as natural as possible, while facing with natural brick is much more expensive.

In addition, the products have a small weight, respectively, the design itself does not exert a large load on the building. It should be noted that the facing work with the use of bricks is much more complicated and longer than when using panels. And also when siding with siding is much less dust and dirt. The use of special insulation is not required, it is quite suitable standard materials.

Siding "under the brick" will serve the owners of the structure for a long time, because the declared service life can reach 50 years, which is undoubtedly less than when using natural materials, however, the difference in price covers this nuance.

In addition, the panels perfectly preserve color and other external data. Their range is very wide, which allows for lining in various versions. Among the disadvantages of the material can be noted its ability to expand or contract under the influence of temperature differences. Improper installation of panels can damage the entire structure, so it is important to strictly follow the technology to minimize unpleasant consequences. In addition, upon closer inspection, it still becomes clear that siding is not a natural brick.

Payment

To purchase the exact amount of material needed for the work, it is very important to make calculations correctly. First of all, the length and height of the walls or those areas on which facing will be carried out are measured. However, it is impossible to say with accuracy that the calculations will be accurate, because there is always a risk.For example, to fit the picture, additional materials will be required. Experts say that these costs average about 10 percent.

The main influence is the length of the wall. The smaller it is, the less material will be spent in the end. Brick imitation panels are mainly produced in the standard size - 1120x472 mm.

In specialized stores work competent staff who can help calculate the required amount of materials. And this service is found on the websites of manufacturing companies.

Nuances when buying

When buying a siding you need to consider the main points that make up the cost and quality of the product. For example, two packages of products that are visually similar may have a significant difference in price.

This is influenced by several factors.

- Primarily, the cost depends on the raw material from which the product is produced. Foreign analogues are composed of European raw materials, respectively, the price can not be low.

- The impact is also on the country in which the siding was manufactured. Local panels are cheaper than foreign ones, since in the second case the price includes transportation costs.

- The reason for the difference in cost may be the proximity of the manufacturer and seller of the goods.As a rule, making a purchase from an authorized dealer, you can get the product for the price below market.

Preparation for installation

After the purchase of basement siding comes the turn of finishing works. First you need to prepare the surface. Before fixing the crate, the base must be cleaned and leveled. In some cases, the craftsmen attach the panels directly to the wall. However, experts advise not to use this method even if there is a perfectly flat surface, since it is the batten that will help the material to avoid deformations during use.

The most convenient for this type of work is a profile made of metal. It has a long service life, quietly transfers the effects of a wet microclimate and does not require additional treatment with protective agents, unlike wooden structures. If the panels are used only for facing the basement, it is recommended to arrange the crate horizontally. The bottom is mounted at a height of about 15 centimeters from ground level.

This moment is especially important in cases when the building is located in a climatic zone that is not distinguished by high temperatures.

If the house is completely sheathed with siding, a vertical crate will be more convenient. It is not necessary to make a frame, moving in both directions at the same time. However, it is necessary to maintain the same remoteness of the elements from each other. It should be borne in mind that not all manufacturers offer strips for internal corners. This information should be clarified when purchasing materials.

Installation

The socle siding imitating a brick has its own specifics in the name of individual elements. Before you install, you need to have an idea about it. For example, a part that is a fastener for the first panel at the bottom of a building is called the starting strip. The final panel is framed by a fitting profile. Both internal and external corners are provided for the joints. Pads and other additional elements are used to firmly join the elements.

First of all, the starting profile is established, focusing on the limitation of 10 centimeters to the corners of the walls. Further, the number of panels is calculated by converting the entire length of the building into centimeters and dividing the resulting number by 112.It should be borne in mind that the length of the last panel should be more than 30 centimeters. After this comes the turn of installation panels. Works are performed from left to right, the edges of the products are treated with sealant.

We must not forget about the control of the gaps between the elements. The joining of panels with the angle should be done very carefully, because the correctness of this work depends on whether the structure is deformed with a possible displacement or expansion of the siding. Nails or screws are used for fastening, they must be located at a right angle, and it is recommended to use a backing. Further, the formation of rows. It is necessary to follow the pattern coincidence so that the brickwork looks as natural as possible. Relative to the previous row of the panel should be shifted by 15 centimeters.

Siding should fit without the use of physical force. At the final stage of the work, the panels should be fixed in the area of the corners with special elements, and then the facing of the next wall should begin. The fitting profile is installed in the final itself and is fixed on the foundation.The edges of the siding hide in it, after which an additional treatment with sealant is carried out.

If necessary, the angular bend is required to heat the profile so that it is easier to take the desired shape.

How to carry out installation of a socle siding, look in the following video.