Vinyl siding: characteristics and dimensions of panels

There are a large number of materials for cladding facades of buildings. Along with natural raw materials, synthetic products are widely used, which on the positive side manifested themselves during operation. These materials should include vinyl siding on the market in a wide variety.

Types, types and colors

Polymer products today are used everywhere, in almost every field of human activity you can find products, objects or structures made of plastic. Not an exception was the construction industry. In this area there are also polymeric materials, among which it is worth to highlight vinyl siding, used for exterior work in the sheathing of buildings.

It was plastic panels that became the leaders in popularity among the finishing materials for facades. With the help of such panels, low-rise houses, garage structures, household buildings, bathhouses, as well as public buildings - shopping kiosks, office buildings, gas stations - are being finished.

PVC products are notable for their appearance. There are varieties of siding that mimic the finishing of natural materials, such as wood or natural stone.

In addition, the elements of polyvinyl chloride are not subject to rotting, do not burn, and also provide a high level of protection against external factors, are quite simply installed and are durable.

The main task of vinyl siding is facing the foundations of houses.

Taking into account the area of use, plastic elements can be divided into three main groups:

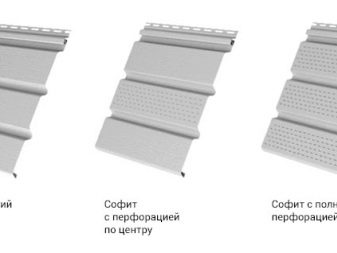

- Soffit - similar products are used for horizontal finishing. Quite often, such material is used for roofing. There are several subspecies of polymer raw materials: perforated siding, solid and panels with perforations in the center.Due to the perforation on the elements provides additional ventilation grounds.

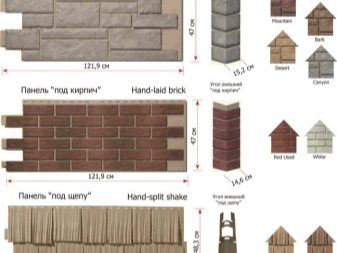

- Panels for the base - they are products of small size, a remarkable feature of which is enhanced strength. A similar property of the material is achieved due to the siding thickness, which is twice as much as usual, usually this parameter at the slats is about 4 mm.

The strength of the products provides them with resistance to the possible mechanical stress that is possible during the operation of the building. However, this does not affect the mass of the panels in any way, so there is no need for additional strengthening of the foundation of the structure.

- Wall siding - this group of products is used for plating vertical bases. Elements are smooth, relief or repeating the texture of natural materials.

There are several varieties of vinyl siding profiles for sale:

- shipboard, the distinctive feature of which is the presence of two bends;

- Herringbone - similar elements have one bend;

- double and triple herringbone - which differ from each other in the number of bends;

- block house - elements of such products resemble the trim log.

Based on the form of vinyl products, there are three types of products on the market:

- the elements consisting of one lath are marked with the letter S;

- panels consisting of two rails, they are denoted by the letter D;

- triple siding, which manufacturers label the letter T.

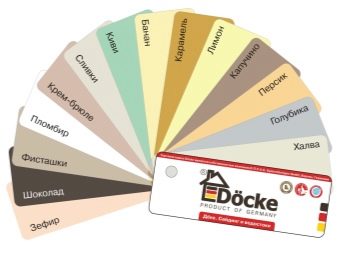

PVC panels, which are offered to the consumer by domestic and foreign manufacturers, are presented in a wide range of colors, due to which it will be quite easy to choose the necessary shade of products for plating.

Focusing on the color design, products can be divided into the following categories:

- white panels;

- color siding;

- products of pastel shades.

The latest product group is the most popular. The demand for such a color scheme is due to the possibility of a harmonious combination of similar solutions with other materials and shades, in addition, elements of pastel colors have a lower cost in comparison with panels of bright colors.

The high cost of products rich shades due to the presence in the composition of coloring additives, which cost quite a lot.But the use of expensive components for dyeing directly affects the durability of such panels - they acquire excellent resistance to the influence of ultraviolet radiation, due to which they do not lose their original shade for a long time.

Characteristics and requirements

The main advantages of polymer siding, used for exterior finishing of buildings, is its resistance to environmental effects and atmospheric phenomena, in addition, compared to natural wood PVC panels do not suffer from insects, the formation and development of various microorganisms on the elements is excluded.

A small mass of plastic construction also plays an important role in choosing this particular material for home decoration, since there is no need to use special construction equipment for the installation of panels.

As practice shows, veneering with vinyl siding will be productively operated for at least 50 years, and the presence of a huge number of connecting parts for products will allow installation in the shortest possible time.

Taking into account the technical characteristics of the material, it is necessary to highlight a number of basic elements that make up the product:

- Polyvinyl chloride Its products contain about 80%, the level of quality of the finished product will depend on this substance. It should be noted that the sale is siding, which can attract buyers at low cost compared to counterparts from other manufacturers. Due to its low price in the process of manufacturing products of secondary raw materials, which adversely affects the performance of the skin in the future.

- Calcium carbonate - this component is present in the composition of the lower layer of the product, as a percentage of its presence is about 15%. The main function of the ingredient is to fill the structure of the panel.

- Titanium dioxide - with regard to this substance, it is included in the composition of the upper siding layer, its share in the material is 10%. It is necessary to maintain the color of the material, as well as for the stability of the structure of the product. Thanks to this component, polymer products become resistant to UV radiation.

- Modifierswhich are responsible for the resistance of the material to mechanical stress. The price of products directly depends on the quantity and proportions of these or other modifiers.

- Coloring pigments - due to these substances the required color of the product is set. During the purchase of products it is worth noting that, depending on the production series, the color of the products may differ slightly.

- Lubricating components - they are not included in the composition of the raw materials, however, they are used to ensure the sliding of the material in the manufacturing process; in addition, the smoothness of the finished panel depends on them.

The release of vinyl panels occurs by extrusion. This process involves pushing through the profiling hole of the entire composition, due to which it takes the form of a tape. After this procedure, the material is cut into products of the desired length, and the working profile is set to the segments.

In modern production of products, two extrusion methods are relevant:

- Mono-extrusion - as a result of this method of manufacturing, products are released, where all the available additives are distributed on the sheet evenly, without taking into account the outer and inner layer.

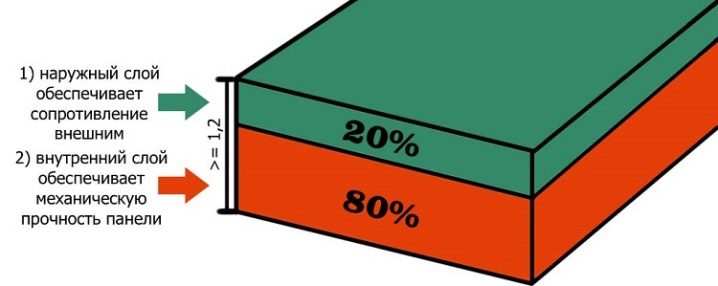

- Co-extrusion - makes it possible to produce products where the quality of the outer and inner side of the material will be different.This feature is very relevant for raw materials, since the upper part during operation is more susceptible to the influence of external factors, so it is important to increase its resistance. Inexpensive co-extrusion siding can be distinguished from the rest visually - its upper layer will be more saturated in color, dyes are usually not included in the second layer, therefore it will be lighter.

There are no Russian standards regarding the norms for the production of vinyl panels, in connection with which issuing companies are guided by foreign requirements and regulations regarding this material.

There is a general standard for the manufacture of vinyl siding, which was developed by ASTM (USA). This organization has prescribed the optimal characteristics, which must be consistent with products from polyvinyl chloride. They are based on foreign and domestic companies engaged in the production of cladding products and components for them.

Among the presented list of standards it is necessary to highlight the following material specifications:

- The thickness of vinyl panels can vary in the range of 0.9-1.2 mm.For products whose service life will be more than 10 years, the recommended thickness will be 1.1 mm.

- As for color, there are standards ASTM D 3679 D 6864 D 7251, which regulate this parameter of products.

- ASTM D2943 standard regulates smoke generation, ASTM D635 - material flammability level.

- ASTM D 1784-81 contains specification for composition.

- The impact strength of a product is spelled out in ASTM D 256 standards.

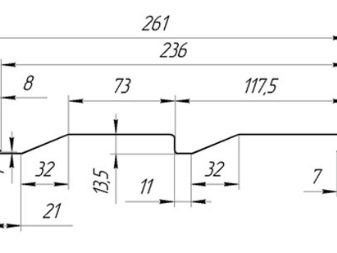

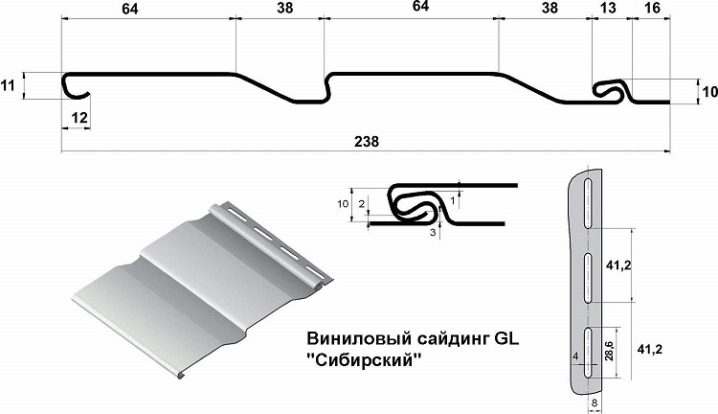

Dimensions and standards

Regarding the size of vinyl siding single standard does not exist, so each manufacturer has an individual dimensional grid for the panels.

We can distinguish the ranges of length, width and thickness of the sheet in which PVC products can be manufactured:

- the length of the element can be from 2.5 m to 4 m;

- width - from 20 to 30 cm;

- panel thickness - from 0.9 to 1.2 mm.

As is the case with slight differences in color, based on the siding issue series with the dimensions of the material, there may also be some inconsistencies. Therefore, it is necessary to purchase all the material and components from one manufacturer to avoid problems during installation and reduce the attractiveness of the exterior cladding of the building.

Calculation of material and components

Accessories for vinyl siding is available in various sizes and configurations. And all the parameters of the elements will be different not only on the basis of the series, but also taking into account the manufacturer of the material.

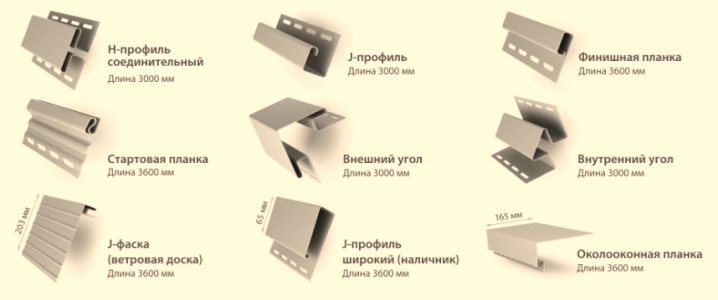

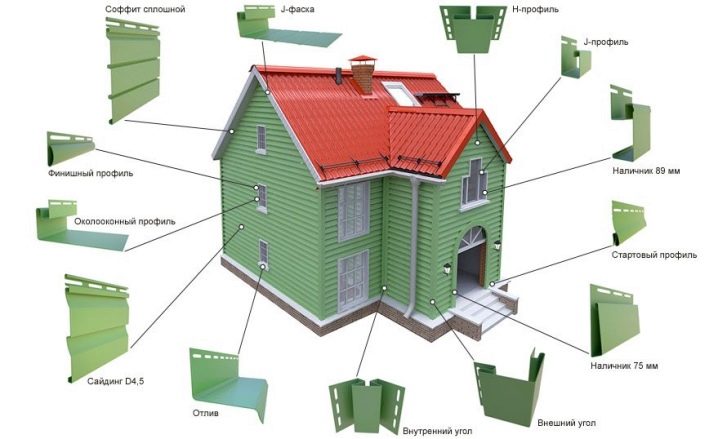

The following products should be classified as standard complementary components:

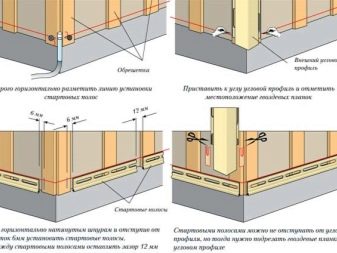

- Starting plate - it is present in any collection and series, from any manufacturer of plastic panels, since it is a mandatory part necessary for installation. It is with the fastening of this element that the installation of the entire structure begins.

- J-profile is a product that is used for covering vertical joints - window or door openings and spotlights.

- Outer and inner corners.

- H-profile - the main purpose of the element is to connect the planks in cases where the installation of overlap panels is not provided.

There is a list of original accessories for vinyl panels.

They are not found in every manufacturer of these products:

- finishing bar - its task is to trim vertical joints, that is, it is essentially the same as the standard J-profile;

- window plate - acts as an analogue of the J-profile, however, has a more complex configuration;

- the casing - used during work near the doorways, and, unlike the J-profile, it has a slightly different device.

When planning the purchase of original components, it should be borne in mind that the cost of the elements most often exceeds the cost of the material for plating.

In order to carry out the installation of vinyl siding yourself, an important issue will be the correct calculation of the amount of material to be trimmed, as well as the additional elements needed to fix the panels.

Calculations are made on the basis of the building plan. First of all, the total facade area is divided into several components to determine the area of each base. The size of window and door openings is taken away from the total value of the facade area. Given the size of the skates and roof, you can calculate the size of the roofing overhangs, which are hemmed with soffits.

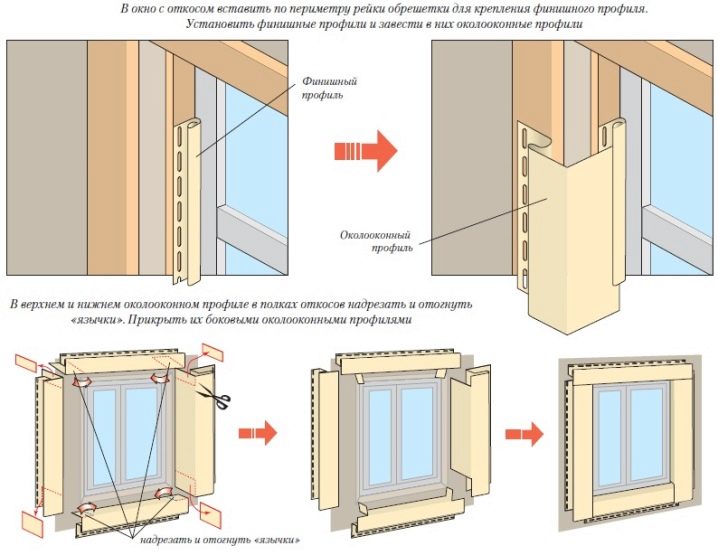

In addition, you will need to count the number of additional trim, priokonnyh slats and other components that are used to mount the panels. In order to accurately calculate the required number of such elements, you should have a clear understanding of the process of installing vinyl siding.

In addition, during the calculations of working material and components it should be understood that the resulting quantity will indicate the amount and list of materials when using products without residues in operation, which cannot be achieved in most situations. That is why, noting all the values, they should be increased by at least 10% to help solve all sorts of problems that may arise during the installation of panels.

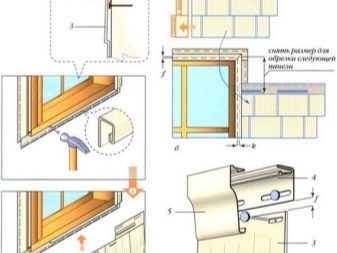

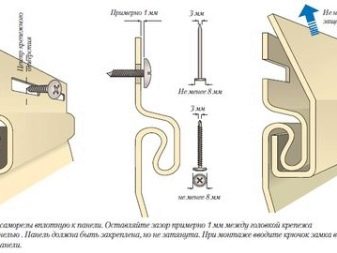

Installation of plastic panels is a simple process. With the tools that almost every owner has, everyone can do this work. To install you will need a level marker and screwdriver. Installation of profiles at the expense of their specific device involves the fastening of products one to another, close to each other. Thus, the joints of materials will overlap with the material following them.

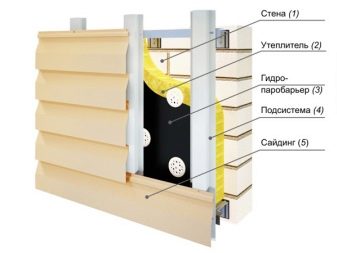

For fixing siding to the facade, lathing is made of wood or metal. Thanks to this method, it is possible to hide any unevenness of the base, however, this will not affect the quality of the installation of the material, the main thing is that the crate be built strictly according to the level. Fastening panels occurs horizontally below.

In the next video you will find a video instruction on installing Holzplast vinyl siding.