Siding: the types and scope of their application

The choice of siding for exterior work is carried out quite often. This is partly due to the functional characteristics of the material, and partly due to its decorative qualities. It is not so important for what reasons you chose to veneer with siding. But before you make a purchase, you need to understand the many intricacies and nuances of this material.

Special features

Siding - material for exterior cladding of buildings and structures. It appeared in the 1950s, when a group of builders decided to arrange the boards not as usual “butt-butt”, but rather overlapped, as a result of which the moisture permeability of such a facing was greatly reduced. Of course, the first siding coatings did not last long, because they were mostly made of wood.

Now there are many options from which you can make siding. Both materials and appearance of panels differ.But all the diversity of species does not guarantee that any of the varieties will be completely devoid of deficiencies. On the contrary, many complain that the variety of siding only confuses.

However, at home, sheathed with siding, are becoming more common. A significant role, of course, is played by the characteristics of the material. Looking ahead, you can rank them versatility and low price, as well as excellent performance. However, many are not attracted by the urbanistic and practical functions of the material, but by its appearance.

Despite the abundance of various options, in the traditional sense siding is presented as a kind of finishing shipboard. By installing the siding panels in the right way, you will be able to create a cozy look for the facade. A wide variety of options will allow you to choose the most suitable sample, while siding will not look cheap. On the contrary, a beautiful decoration will be evidence of the refined artistic taste of the homeowners.

Advantages and disadvantages

The siding material has a lot of advantages. The positive features include the following:

- Durability. The service life of siding with proper care can be up to 50 years.

- Wide decorative possibilities. Due to the abundance of varieties, you can set the facade upholstery in almost any stylistic direction.

- Ease of care. Exterior finish of this material does not need periodic tinting. Caring for her, too, is extremely simple.

- Ease of working with material. Siding is light and flexible. The panels are equipped with a convenient mounting system. Thanks to these features, the lining of this material can be carried out even alone.

- Sustainability. Siding panels do not react to temperature fluctuations, they are not susceptible to corrosion or harmful effects of insect pests.

- Barrier role. Siding copes with its protective function, protecting the draft walls of the building from all kinds of destructive influences of environmental factors.

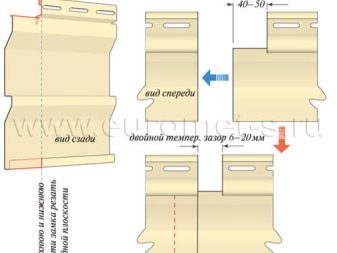

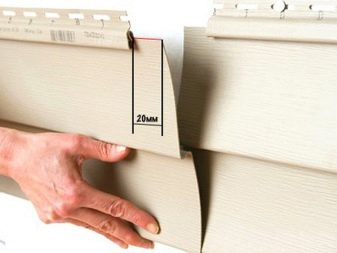

- The ability to "breathe". Since the design of the panels provides special ventilation gaps, the building is able to "breathe." In addition, the condensate between the siding and the rough surface does not accumulate.

However, not all so simple. The material has a number of disadvantages:

- Low environmental friendliness. Siding, even made from natural materials, goes through many stages of processing, therefore it cannot be called environmentally friendly. In addition, the vast majority of models on the market are made of synthetic materials.

- Flammability. A number of samples support combustion well, therefore it is impossible to call this type of finish fireproof.

- Fragility. Some species are extremely unstable to mechanical stress, especially as a result of a long stay at low temperatures.

Kinds

There are many types of siding. First of all, its categorization is made according to the type of material from which it is made. Some materials are suitable for decoration of country houses, others - for those that should seem reliable and sturdy. In any case, for the design of private estates fit not all options.

Before you choose a material, you must decide on the form of siding. So, distinguish between vertical and horizontal. Vertical distribution is not received, because it does not look very comfortable.You can meet him mostly in non-residential premises.

Another thing - the horizontal version. He successfully stylized a tree. The panels are available in two forms of masonry: under the ship's board and herringbone. Herringbone is more common because it is considered optimal for protecting rough walls from contamination, moreover, dirt flows from its inclined surfaces, so care for walls decorated with this type of material is facilitated.

Foamed

Foam siding is produced by extrusion of foamed PVC. The material is lightweight, porous, which has both a positive value and a negative one. On the one hand, the increased porosity allows the material to well hide noise and vibration. On the other hand, porosity does not prevent heat loss, which is why it is imperative to lay a film for hydro and thermal insulation under the material.

The foam version has a high resistance to mechanical stress, such as bumps or scratches. Hurt it is not so easy. If, even under special circumstances, the panels were damaged, this does not lead to the loss of its protective properties by the material.Panels can be operated in virtually any climatic conditions. They do not contract and do not expand under the action of temperature drops.

As a rule, the foam type imitates a plank covering, including not only its color, but also a characteristic woody pattern. This is achieved by embossing.

The option can be used on the facades of any material: brick, block, wooden, frame. Fastening is made easy. Each of the manufacturers himself provides for one or another set of dobornik and anchors used during installation. Foamed siding is laid from bottom to top, like other siding varieties. Since the material is lightweight, guides under it can be fixed with an increased step of 70 cm. This will greatly simplify installation and will save time on the preparatory work.

Vinyl

Like the foamed version, vinyl siding is made from PVC. In fact, it is PVC panels with different dimensions. Vinyl versions are stylized not only under the tree, but also successfully imitate some other materials: stone, brickwork and the like.Thanks to a large variety of colors and ornaments, it is possible to choose the right solution for any exterior by making the outer facing of the house in harmony with the environment.

The material has numerous advantages, including not only a wide range of colors. Vinyl siding is lightweight, so you can mount it alone. It also tolerates various atmospheric influences, be it rain or ultraviolet radiation. Vinyl, though fade, but evenly and not much.

If the material is mounted correctly, it will not lose its performance properties at extremely high (up to +50 degrees) and low (up to -50 degrees) temperatures. In addition, the cost of this option is quite small.

However, vinyl has a number of significant drawbacks. So, during the installation it is necessary to take into account that it tends to expand and contract depending on the temperature conditions. Vinyl panels are easily damaged mechanically, so that when carrying out repair and finishing work you need to act very carefully. The material is short-lived by the standards of siding - only 5 years, so you should not rely on long-term operation.

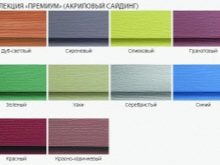

Acrylic

Acrylic models are made from acrylic styrene - a substance that is the newest polymer. Acrylic for siding panels repeatedly exceeds vinyl on a number of indicators. Among them - resistance to fading. The durability of acrylic exceeds the durability of vinyl by 10 times. Other characteristics also did not ignore him. For example, resistance to all sorts of chemical compounds that may be part of cleaning agents is much higher. The amplitude of the temperature fluctuations that this material carries is greater: the spread ranges from -80 degrees to +80 degrees.

It is logical to conclude that acrylic samples last several times longer than classic vinyl ones. Thus, the life of acrylic can be 15-20 years with a slight loss of appearance by panels. It cannot be said that acrylic was subject to slight deformation as a result of mechanical loads: it is much stronger than the vinyl analog in this respect.

When installing it is important to bear in mind that it is made only on a wooden crate. You should not use metal profiles for these purposes.

Gardening panels on the top already have places for their attachment, therefore it is necessary to pass the screws through the existing holes.It is also necessary to leave small gaps between the panels in order to compensate for possible small extensions. In the future, these slots, called compensatory gaps, will be closed with special plastic profiles to match the color of the siding panels.

Wooden

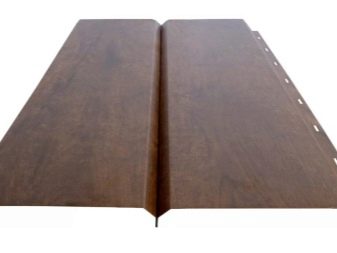

Wood siding, also called glued clapboard, is very different from the one used in facing work at the very beginning of its “career”. Now the pressing of wood chips is completely different technologies. The material has acquired good performance properties and durability: it can last up to 15 years. Paint and varnish are applied on the panels in several layers, which significantly prevents the appearance of fungi and mold.

There are several options for the section of wooden siding:

- Overlap. Boards are arranged with a small layering of one another.

- In a quarter. The variety most closely resembles traditional clapboard trim.

- Groove comb. The appearance is similar to the previous one, but the gaps between the boards are much smaller. Most often found in the manufacture of panels block house;

- Butt. Ordinary wall cladding wood type "ship board."

Among other things, the tree has excellent aesthetic performance. If they sheathe the house outside, then you can not worry about the insulating properties of the material: the tree copes with this role. Due to its environmental friendliness, wooden panels are suitable not only for exterior cladding, but also for interior decoration of rooms, however, the width and thickness of the boards in this case should be much smaller than for exterior work.

Despite all the virtues, wood is not the best option, as the material is highly flammable and burns well, deforms and warps, as a result of which it quickly loses its original attractive appearance. In addition, wooden siding panels are quite expensive.

Metal

Siding is made of three types of metal: steel, zinc and aluminum. Each of these samples is specific, but all metals have similar features. They are as follows:

- Durability. Despite the abundance of equivalent siding materials, none of them can match the metal in durability. Metal elements will be able to serve up to 50 years, while not losing appearance, if you exploit them and care for them correctly.

- Heat resistance. Unlike all others, the metal does not warp under the influence of temperature changes. This will especially please those who don’t like it when they lay profiles over siding to hide compensatory gaps. Here such profiles will not be needed.

- No fungi. The metal is not exposed to infection by fungi or mold, microorganisms that can destroy it do not live in it. The only thing that can be encountered is corrosive processes, but they can only occur if the metal strips have not been properly processed in the factory.

- High strength. No one doubts that the metal is much stronger than other materials. This radically affects its performance, which can not be damaged by any atmospheric phenomena.

- Incombustible. Since metals do not sustain combustion, they can be safely attributed to fireproof raw materials. Having issued the house by means of such siding facing, you will minimize risk of ignition of the construction.

Different types of metals give siding panels additional advantages and disadvantages, so it makes sense to consider each of them in more detail.

Zinc

Despite the highest strength characteristics, the zinc variant did not find due recognition among domestic consumers. This is due to a very large weight of the material, its high cost, as well as a small selection of colors. So, the weight of one cubic meter is 10 kg. It is logical to note that such a lining will significantly affect the weight of the whole structure and, therefore, greatly increase the load on the foundation. As for colors, only gray and black panels are available.

Steel

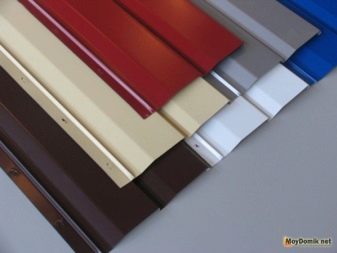

This option is valued so highly due to several of its features as a technical content, and external. First, the panels have a large range of dimensions. They are available in versions from 12 cm to 55 cm in width. The length is from 2 to 6 m. Secondly, coloring and processing allows the material to be as close as possible in appearance to the type under which it was stylized (usually wood or stone). Also, the polymer coating used in the processing of metal, allows you to create a beautiful combination of metal roof and walls decorated with steel siding.

However, the panels can be painted not only by applying a polymer coating on them. There is also powder paint staining. If in the first case the range of colors is very limited (there are only six available colors), then the powder paint allows you to give the siding any color.

Steel siding refers to the universal. This means that it does not have any definite predisposition towards vertical or horizontal placement: it is possible to lay both this way and that way.

It also plays a role that siding is not produced with embossed, but only smooth. The desired effect is achieved by staining. However, there is one of the varieties that can no longer be found on the market, since it is made only from steel. These are perforated siding panels.

Steel siding can be mounted only on the sheathing of metal profiles, wood is not suitable for these purposes - it simply will not survive. In addition, the wooden frame is subject to rotting and in the case of not very high-quality processing panels of steel at the joints with wooden elements can begin to climb. So, choosing steel siding as a facing material, you can start work at any time, regardless of whether it is summer outside or winter.

Steel panels look attractive, and therefore they are chosen so often for cladding the facade of a house for year-round living. However, there is one drawback: insufficient strength to shock loads. Steel does not have elasticity, so if you leave a hall or a dent on it, it will not take on its former appearance, and in the future it will be necessary to replace siding to maintain an aesthetically appealing look. However, this does not affect the strength characteristics.

Aluminum

This option is quite expensive, which is why it is rarely chosen as a facing material for private households. It has considerable weight, which is why it is better not to try to install such panels alone. The advantages of aluminum include the choice of both embossed and smooth surfaces. Due to this, maximum plausibility is achieved: aluminum panels are almost indistinguishable from wood. It is worth noting that facing such material does not weigh down the overall construction of the house, does not increase the load on the foundation.

However, aluminum has more minuses than pluses, and among them not only high prices.This material is easily deformed, as a result of which transportation is problematic. By accident, it can be bent at the moment when it will be transported. Straighten the panel back will not work and the fracture will remain. In this regard, during the receipt of the goods must be carefully checked components for the presence of any dents or creases.

Separately, it is necessary to make a reservation that aluminum is a valuable metal, therefore it is dangerous to veneer it in a structure in which they do not live all year round. The walls can simply be torn off for the sake of non-ferrous metal, which is highly valued when it is delivered to the scrap metal collection points.

Cement

Cement samples are made from cement and cellulose. This species is relatively young. It is used not as long as wooden varieties, and appeared at the same time with metal-siding panels. The idea to use cement came when there was a need to find a material that does not support burning at all. This is extremely important in cases where more serious fire safety requirements are imposed on buildings. Cement siding is an ideal facing material for such structures.

It is used for cladding of residential buildings rarely enough due to its many shortcomings. The first of these is the price. It is much higher than on vinyl analogs, which greatly benefit in appearance.

Also, weight plays an important role: the cement slats weigh quite a lot, as a result of which there is a need to make reinforced crate.

When working with this material there are many difficulties, since it is first necessary to take enhanced security measures. The fact is that as a result of sawing panels, toxic silicon dust is released into the atmosphere, inhalation of which is fraught with health problems.

It is necessary to protect the respiratory tract with a quality respirator every time you start sawing, which may not always be convenient.

Recently, a new improved form of siding panels - fiber cement. This material is devoid of many of the shortcomings of the traditional cement "progenitor".

Fiber cement

Fiber cement siding is often called the boards because of their incredible similarity with wood.Another similarity between fibrotsement and wood is in their naturalness. Fiber cement is an environmentally friendly material that has unique strength properties:

- resistance to burning;

- not subject to pest infestation;

- does not perceive chemical adverse effects;

- tolerates freezing temperatures.

The composition of fiber cement includes directly cement, river sand of fine fraction, sawdust, mineral additives and water. Previously, they added asbestos, but after it became clear that it was hazardous to health, it was excluded from the composition. Such a mixture after complete drying on the strength is not inferior to the stone. From it you can sculpt anything, so it is easy to give a drawing to siding panels from fibrotsement.

In addition, for greater certainty, they can be painted, and then periodically update the paint layer or completely replace it.

Fiber cement siding panels are necessarily equipped with metal or vinyl components for ventilation, which can also be painted.

The only weight deficiency is the high cost of materialbut many homeowners, who have cladded them with fiber cement panels, say that the material is completely worth the money. Installation is also not easy, because you have to spend a lot of time on the arrangement of ventilation.

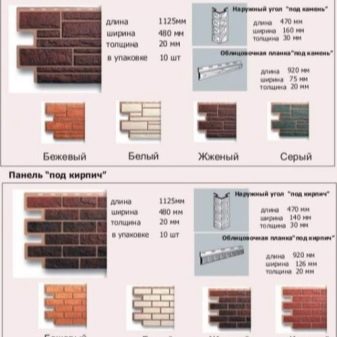

Ground floor

The socle siding is carried out in the form of integral panels of a small format. Material production can be any, but most often for this purpose is selected, either vinyl or metals. Some requirements are imposed on the basement panels, the main of which are moisture resistance and durability. Such panels are used to finish the basement of the building. On the one hand, this allows you to protect this part of the building from weathering, on the other - to decorate it.

Among others, ground siding should meet the following requests:

- No shrinkage changes. It is unacceptable that the basement panels expand and contract due to temperature fluctuations, so the best materials should be used here. The same applies to their ability not to react to a strong imbalance in temperatures of the rough surface of the walls and the external environment.

- Impact strength. At the bottom of the building has a large load, and therefore it is necessary that the panels do not crack and do not deform as a result of mechanical effects.

- Ease of installation. In which case the panel should be easy to dismantle and install again in order to fully carry out the necessary repairs.

When choosing, it is important to pay particular attention not to the appearance, but to the technical characteristics, since the basement siding is more needed to serve rational purposes. Be sure to pay attention to the manufacturer.

Block house

The name "block house" comes from the English "block house" - a block house. In the West, this name designates houses, hastily erected from blocks and looking like logs. In Russia, the so-called siding panels of a specific form are called, after which any, even a frame house, takes on the appearance of a good Russian hut or an exquisite Scandinavian chalet.

Blockhouse panels or lamellas are made from different materials:

- metal (mainly aluminum);

- vinyl;

- tree.

Each of them is specific. For example, wood and metal are environmentally friendly.Wood panels look the most plausible, even despite the type of wood from which the block house is made. Metallic ones allow to get an approximate effect, although they are more durable, because they do not rot and do not corrode due to special treatment. Vinyl options are the most popular of all. In many ways, this demand is achieved due to the cheapness of the material and its attractive decorative properties. However, vinyl is a synthetic material that repels many from it.

Installation of a block house is not so simple. The fact is that the surfaces must first be prepared and treated with antibiotics, since the greenhouse effect formed between the panels and the rough walls of the facade is a favorable environment for the development of bacteria and microorganisms, fungi and mold. It is also necessary to provide additional ventilation gaps.

Ceramic

Ceramic siding was created in Japan about 40 years ago. Today it is one of the fairly well-known materials, with both their fans and opponents. The basis for ceramics is fibrous cement, which are not just dried,as in the classic version, but in a special way they are fired, hardened, and subsequently covered with several layers of coloring materials.

However, the paint can not be called ordinary, because it is similar in composition to ceramics. Hence the name of such panels.

Ceramic siding is used with a wide range of rough coatings, from wood to reinforced concrete. This option is ideal for operation in the Russian realities, since it has the following advantages:

- Resistance to negative environmental factors: precipitation, temperature extremes, natural phenomena, ultraviolet radiation and other

- Preservation of the original color throughout the entire period of operation. This is achieved through the use of modern patented technology of coating with special ceramic paint.

- High noise insulation properties of the material, which do not allow the penetration of extraneous sounds into the house, even if it is located on the side of a busy highway.

- Excellent thermal insulation, with which none of the materials could not be compared. Thus, the manufacturer claims that the thermal insulation quality of ceramic siding exceeds the quality of concrete by 10 times.

- Since the material has a high resistance to burning, it does not need to be certified for fire safety.

- Ceramic siding has no asbestos. On the contrary, it contains only natural ingredients, whereby it can be stated that this material is environmentally friendly.

The ceramic variety has several drawbacks: the complexity of installation and impressive weight, as well as the cost is above average.

Scope of application

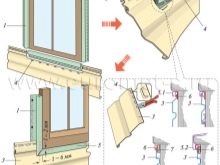

In most cases, siding is suitable only for exterior decoration. This applies to the vast majority of cases. When facing it is necessary to act carefully, especially when processing windows and doorways. In order to beautifully arrange them, you will need special additional profiles.

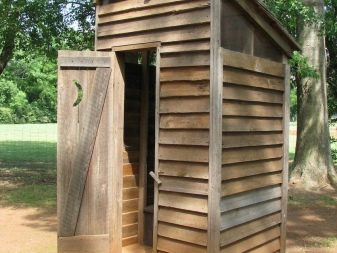

Some varieties can be used indoors. For example, wooden panels, more reminiscent of eurolining or ordinary, are perfect for creating an interior rustic, chalet or Provence.

If at the exterior cladding the quality of wood raw materials turned out not to be on a level and could compete with the rest except for decorative properties, then inside the room there is no equal to the tree.

Properly treated panels can also be used inside the outbuildings, for example, outdoor toilets and showers. Vinyl is excellent for these purposes, since it reacts favorably to moisture getting onto it, and inside the closed structure it will be less deformed in the process of changing temperature conditions of the weather.

In short, siding can be used almost everywhere, the main thing is to choose the right size of panels and the material from which it will be made. Keep in mind that It is best to choose wide and thick panels for facade cladding, and narrow ones for interior decoration.

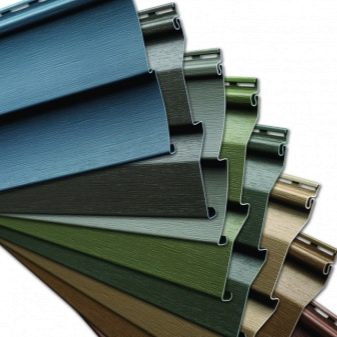

Colors

You can find siding of any color - it all depends on what material is selected. The most classic are all shades of brown, because on this background it is easy to imitate a woody pattern. You can also often see gray models, as well as white ones, which in some cases look festive and solemn, and sometimes give the house a dull and state-like appearance.

The largest variation of colors, of course, in vinyl models. Here there are all sorts of options, ranging from classic brown, black and white to lemon,peach, blue. There are many shades, for example, mocha, cappuccino and other shades of brown. You can find such bright colors as kiwi (bright green), pomegranate (purple-red) or sakura (pale pink). In short, everyone will find here something to your taste.

If you choose wooden siding, then a lot of attention is paid to nut, oak colors, as well as a shade of mahogany.

The latter looks the most beautiful and expensive, if it is decorated with only some bright details, for example, the frame around the window, door trim, corner profiles. Oak, especially stained, is often preferred for finishing basements. Looks beautiful if the main structure is the color of light oak, and the finish is made in the shade of "bog oak".

Manufacturers

There are many manufacturers offering their products on the market of siding panels. Sometimes it is difficult to distinguish really high-quality options from low-grade ones, especially if there was no such experience before. We offer you a list of manufacturers who have received the best reviews from buyers:

- Alta Siding. Russian companywhich is one of the leaders in the production of facade cladding materials. Offers panels in a large color range. The quality is excellent.

- Kaycan. Producer from Canada, who proved himself to be an excellent one. Engaged in the production of siding for over 40 years. During this time, the plant has managed to win many fans of its products around the world.

- Mitten. Another Canadian manufacturer, which appeared on the domestic market relatively recently - in the early 2000s. The plant produces not only the siding panels themselves, but also additional accessories designed to facilitate the installation of siding.

- Tapco Group. A company from the United States, deserving a lot of positive feedback about its products. Of particular note is the “Foundry” line, which enjoys the greatest popularity due to its interesting ornamentation and high performance. It is worth noting that the manufacturer gives a fifty-year warranty on its products.

- Nichiha. The famous Japanese manufacturer specializing in the production of ceramic siding. The company has almost monopolized the siding market in Japan, which indicates that it actually produces worthwhile products.

Tips and tricks

Before proceeding to the selection or installation of siding panels, it would be nice to familiarize yourself with useful tips and take them into account in the future. Experts give several recommendations designed to help in the difficult choice of siding. So, when choosing, it is necessary to pay attention to the following factors:

- The uniformity and versatility of color. Be sure to pay attention to the fact that the panel was painted on both sides, and not just outside. Uniform color indicates that in front of you, most likely, a sample of good quality.

- Thickness. There should be no difference in the thickness of the panels. Over the whole area they should be equally thick. The same applies to the width, if, of course, you have not chosen curly options.

- Mounting holes. From above, inspect all the holes under the nails. They must be the same shape and size, neatly executed, located on the same line. If this is not the case, most likely the production technology was not respected.

- Surface. If vinyl siding is chosen, then it should be completely matte from the front. This is due to the fact that shiny glossy surfaces more strongly attract the sun's rays,therefore, they burn out and deform.

- Warranty. Be sure to check what the warranty period for the product. Its large length indicates that the manufacturer is not afraid to undertake obligations, therefore, he is conscientious.

Care

Care for siding panels is easy. It is enough only from time to time to wipe them with water with a non-aggressive soap solution. If desired, and in the presence of strong pollution, you can use Karcher - a special apparatus that supplies water under high pressure and a jet literally knocks the pollution from the surfaces. However, with Karcher you need to work carefully, as you can accidentally damage the panels and, therefore, ruin them, especially when it comes to metal cladding.

Do not use abrasive cleaners or substances. They can scratch the surface of the panels, and they will not be able to return the former attractive look.

In the presence of heavy dirt, you must use a soft brush. You can choose a car option, the main thing is to ensure that the brush is soft and does not injure the surface.If the manufacturer states that the siding is resistant to chemical attack, then you can use a solvent and a cloth. Pay attention to precautionary measures: it is necessary to work in gloves, and also it is necessary to protect the respiratory tract.

Beautiful examples

Sometimes some people adapt any material to their needs. It happened in this case. Here the whole house is sheathed with a basement siding under stone. Nevertheless, this decision can be called a winning one.

In cases where the siding exfoliates, you will need to dismantle it. This can happen due to non-compliance with the plating technology, poor quality of the material, the wrong choice for their climatic conditions - mass options.

Beautifully laid vinyl siding is difficult to distinguish from wood, even if viewed from close range. It should be borne in mind that it is better to choose light samples: it is less noticeable that they fade in the sun.

Block-house panels allow you to create a decent imitation of a real log lining. However, it is important to correctly handle the corner joints.It is better to entrust such work to professionals, and not every one of them is ready to cope with a similar task.

Video instructions for installing vinyl siding, see below.