The details of the installation process siding

In the decoration of the walls are widely used a variety of materials. Not least among them is siding. But these simple and beautiful-looking panels need to be mounted using a special technology.

Special features

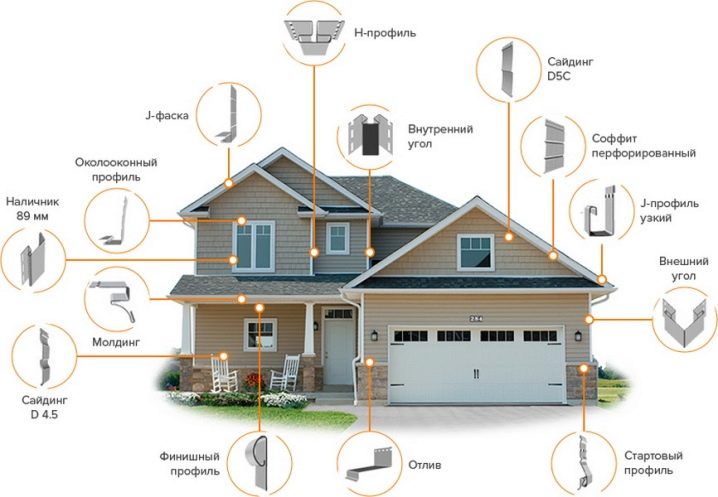

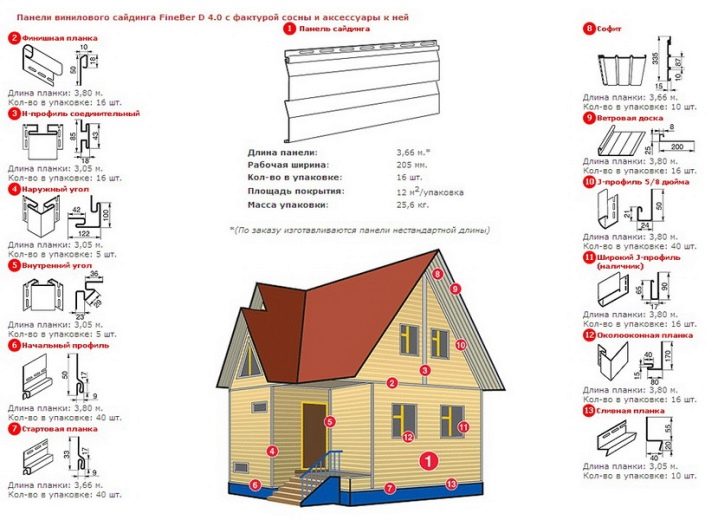

To sheathe the walls of the house siding without any problems. The reasons for the popularity of this material are obvious - the variety of types and forms, reasonable price. Wall panels are supplied by various companies from many countries, so there is something to choose from. But a wide range of varieties does not allow to make the final choice, analyzing the siding as a whole. It is recommended to calculate in advance how many and what details you will have to use, how to connect the blocks with the bearing wall and between themselves.

Siding was first used in the 19th century in North America. It was then that it was decided to mount the boards not with the butt joint, but “with a raid”. This avoids the ingress of rainwater through the lining and damage to building structures. The lack of protective equipment did not allow for a long service life of structures. Only in the middle of the last century did vinyl panels (PVC) enter the market; Year by year, siding is becoming more and more perfect, it has long overcome the "childhood diseases" that prevented competing with other materials.

In addition to differences in the basic substance, the difference may also apply to the color of products, and to their texture. Every self-respecting manufacturer supplies the market with a variety of key siding. In the range of modern firms are imitations of natural stone, wood. It is harder to make such an imitation of aluminum than vinyl, so the fee for such blocks will be more. The remaining features are more conveniently disassembled by the example of individual types of material.

Types of material

In appearance, facade siding looks like a wall paneling, but it cannot be considered a perfectly hermetic solution.This is rather a plus, since 100% clogged walls would quickly deteriorate. Part of the varieties of panels for exterior decoration is able to work for about half a century, and cleaning them is not particularly difficult. The vinyl variety is only called that, in fact it is formed from polyvinyl chloride (PVC).

Such constructions:

- mechanically flexible;

- few fade and crack;

- easy to install;

- differ in insignificant weight;

- do not cause environmental damage;

- allow to operate the system for a long time at high and low temperatures;

- do not corrode.

Flexibility during installation is quite normal for most work. PVC panels can be painted in a variety of colors, the selection of pigment occurs individually. Polyvinyl chloride is indifferent to acids of almost any strength. This means that even if there is a large industrial enterprise nearby, there is no risk. Fastening is allowed in horizontal and in vertical plane.

But the vinyl version is soft, it does not allow for the selective replacement of deformed blocks. We'll have to disassemble the entire lined wall.Aluminum constructions should be preferred to those with priority is durability. The downside of this advantage is an increase in mass compared to PVC, but it is not very significant. Aluminum is easy to install, and at the same time it even reliably experiences stress from squalls and strong, steady winds; therefore, its value must be recognized as justified.

Classic metal siding is formed from steel sheets with an external zinc layer. Such material is able to imitate natural wood, and developers often use this circumstance. After all, the continuous smoothness of the surface is not too attractive in design terms. To make the metal work longer and not fall victim to atmospheric elements, it is covered with a polymer film. Designs with a lock are assembled easily and quickly, there is no need to spend money on fasteners.

Metal will have to be monitored constantly, because it can degrade very quickly. One has only to appear a small scratch, and now the development of corrosion begins, and soon it will corrode a vast territory.Fans of new products should think about ceramic siding, which experts recognize the most promising invention. There is no need to doubt safety, because the construction is made from natural clay, and not from doubtful components. The outer layer may resemble the surface of a simple wooden house.

By the way, wood itself is also quite good for making siding. Such a solution is more expensive than many others and is called a block house. But if you wish, you can buy other options - a board or a fake timber. Allowed to use in the manufacture of not only solid array, but also glued blocks. Handling and care are the weak points of wooden siding; even constant attention to it does not allow the material to work for a long time.

Wood tends to swell and warp under the action of moisture - special impregnations slightly improve the situation, but do not correct it in the root. Additional measures of protection together with the treatment of non-combustible substances, insecticides increase resistance, but only with the dream of a natural wall will have to part. A special group is to provide siding for the base, which is not so beautiful, but it protects the wall from damage better.This is the only task of such products, their thickness starts from 0.3 cm. To make a siding for a socle, very strong materials are used, characterized by increased weight.

The use of fiber cement siding implies the use of cellulose fibers. The final stage - the formation of texture, like wood. Such a material easily tolerates the effects of temperature jerks and precipitation. Aggressive wind and fungi, insects are not dangerous to him. The coating provides a quick update of the building and giving it an original look, leveling the walls; it is also non-flammable and retains color for a long time.

Design

Choosing options for facing cottages or private homes, you need to pay attention primarily to the color. Light tones, as in any other areas of design, help to visually expand the volume of the room.

Most often, such a motive means that consumers will choose:

- lavender;

- salad;

- creamy;

- white;

- yellow;

- pearl;

- beige and similar keys.

It is always necessary to remember that each company in the pursuit of uniqueness and the promotion of its original product is trying to come up with its own range of names.It is much more correct not to rely on the usual “name” of color, but to check with the standard code according to the generally accepted table. Then, when finishing there will be no problems and misunderstandings. If the goal is not to distinguish facades relative to the surroundings, it is recommended to use dark panels or blocks with a subtle neutral color.

In some cases, powerful, bright tonalities are chosen, in others - less attention is paid to, and yet not losing the attractiveness. Respectable building, constructed or repaired by reputable owners, simply can not be decorated with frivolous scenes and drawings. For your information: applying green and brown paints is extremely rare. They merge with vegetation, and the house sheathed with siding almost always surrounds a garden, a vegetable garden or just a lawn. If, nevertheless, there is a traction specifically for such colors, it is required to choose them as single accents, and not as a monolithic background.

Harmony transitions are most easily achieved using combinations within the same color. This solution should be applied where there are many structures that go beyond the dimensions of the facade.Violation of this rule is allowed only for designers who are guided by professional considerations. You should never forget about the combination of painting the wall with roofing and plinth elements; they are trying to bring it closer together, and not to create an expressive contrast.

Originality can be shown by using the vertical and horizontal panel layouts on one building at a time; but for beginners whose experience is insufficient, it is too difficult. If the house is very squat, stocky, it is advisable to choose a horizontal layout. Texture is another extensive field for experimentation.

Imitations are quite common:

- bricks;

- stone surfaces;

- real wood.

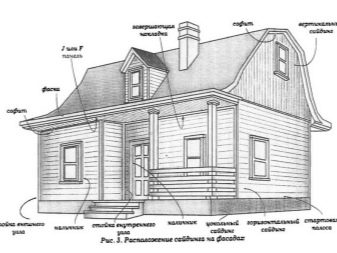

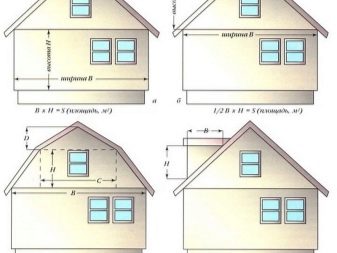

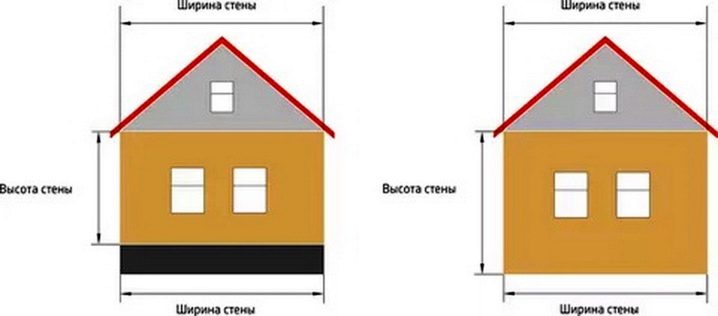

Calculation of the amount of material

Having dealt with the design aspects, it is equally important to calculate the need for a profile, additional elements, components and fasteners by the size of the surface to be trimmed. At the disposal of customers there are several ways to carry out the necessary calculations. Often they rely on the opinion of employees of trade organizations, because they are aware of the features of all materials, they have specialized software for calculations.But even if you imagine a really tuned user, and not a seller’s profit, the lack of accurate drawings and sketches will not allow you to calculate everything accurately. Those consumers who themselves build or repair something professionally, can perform the calculation as accurately as possible.

All other customers should contact the experts and invite them to get acquainted with the object. But it is advisable to call the measurer not related to the company that will install the siding. Controlling extraneous calculations or calculating the need for panels on your own, you need to divide the effective area of the facade by the useful area of a single panel. To the obtained result, the reserve is added for the greatest reliability. Long-term practice of builders shows that on straight walls there is enough stock for cutting at 7%; if the surface is more complex in shape, it is worth increasing it to 10-12%.

When calculating it is necessary to proceed from the useful, and not from the total length of the panels. When walls differ in height, the need for material is calculated for each of them separately, and then the result is added.Subtract from the total area of small dormer windows, ventilation, air conditioning fixtures and satellite dishes are not worth it. This will only complicate the calculation, but will not make it more useful in real business. It is always worth remembering that cladding with siding involves creating a frame that makes the wall longer, and that insulation also increases the area.

Calculation of siding consumption for gables is made separately. It requires a different color, and often can not be limited to standard geometry. Even if the wall is laid out from horizontal panels, it is not uncommon to gables with vertical blocks. In addition, the panels there should be notched on the ends at strictly defined angles. Therefore, the amount of waste, which cannot be used any more, grows sharply.

Instead of mathematical formulas and connecting to sites with calculators, you can use a graphical method. A drawing (sketch) of a wall that strictly corresponds to the chosen scale is applied on a sheet of paper. This approach will give a good result, if everything is measured, and, moreover, without errors. Next, cut the paper strips, which are proportional to the length and width of the installed panels.All those who in their childhood at least occasionally collected mosaics, have already guessed, of course, what will happen now.

It is not necessary to even combine the strips manually. The same visual result gives the use of any graphic editor. Moreover, the accuracy of the calculations (if no errors are made with the removal of dimensions and with geometry) even increases. Increased accuracy allows to reduce unproductive consumption of material less than 7%. We should not forget about the formation of ventilation openings and ducts.

Instruments

To install the siding properly, it is not enough just to choose the right look, deal with the design and calculate the material consumption according to all the rules. Work is always carried out using special tools. If you break this rule, you can not only get a bad result, but also lose the warranty from the manufacturer. And everything will be legitimate and fair, since it falls under the category of erroneous actions of the builders. It is useful to disassemble the technology on the example of vinyl panels.

Hand tools - a hacksaw is simple and for metal, a screwdriver, a water level, a square. All work with them is required to be carried out on a workbench, which is more reliable than without a stand. It is also permissible to use electrical apparatus, such as a circular electric saw. As the danger noticeably grows, it is required to observe security measures. Working with power tools and pneumatic machines requires support even more than manual actions.

To extend the holes in the panels, you need to use a punch. If any panel is out of order, the disassembly hook will help to change it. Since the siding blocks in the upper parts of the walls or under the windows to put hard, they use punches. These devices help to create hooks, thanks to which the panels will hold better and more stable. But anyway, all the work can be done by hand, without recourse to specialized companies.

Training

Even before placing on the wall of the starting plate, it is necessary to prepare the surface in a proper manner;

- finish all other works on the facade;

- caulk the seams in the walls of the log;

- take out unnecessary fasteners;

- prepare the wires and connection points of communications to the output in the rightplaces;

- heat insulation, waterproofing, vapor barrier, acoustic protection (in accordance with the project);

- remove the trim from all openings;

- replace rotten boards;

- strengthen all loose constructions.

Stone, industrial blocks and wooden walls with uneven terrain imply fixing on the crate, which makes the outer layer smoother. Doing crates required from dry wood, which has a moisture content strictly not higher than 14%. Those who violate this rule suffer greatly from the "ongoing" mass. Bars of typical sections are impregnated with antiseptic compounds. If you make the grilles as wide as possible, you can prevent the failure of fasteners, no matter how one or another panel is put.

Mounting crates are around the perimeter of the walls to be finished. It is impossible to bypass the pediments of roofs and the perimeter of windows, other openings. It is better to refuse the lower horizontal grids around the perimeter, since they will block the exchange of air with the external environment. Other laths are placed vertically (if the siding is located along a horizontal line) or vice versa. The gap from one to the other is from 200 to 400 mm; mounting step on the wall - 50-70 cm.

Installation begins by placing angular laths. Between them, the cords are stretched and then the crate is nailed. In order for the distance between the laths and the walls to be adjusted, it is necessary to use direct suspensions or screed lining of wood. Construction levels help to check how vertically and exactly the lathing is put. In the absence of such levels, cords and plumb lines can be used.

Having found the lowest angle, 50 mm move away from it. This line is marked along the perimeter; a water level is used for control. Nails are driven into the corners, but not too deep. The nails keep the cords being pulled in, then the corner profiles are inserted to the corners. The crate of places is marked where the strips for nails should be located. A horizontal distance of 0.6 cm will show where the profiles of the original bands should be placed.

Frame

Mounting frames for siding is necessary to provide moisture repellent and heat retaining layers. The choice of material for the guides - the personal business of builders. But general considerations must take into account all the decisive ones to do the siding themselves. Thus, the increased charge for the metal structure is justified by its durability, mechanical strength.Wood is supposed to be impregnated with liquids that stop the development of pathological fungi and mold.

If you ignore such a requirement, you can face a violation of the integrity of structures in a few years. The crate is placed in the same way as the panel. Screws and nails (if the substrate is wooden) or dowels (on brick and concrete walls) are used for fastening. The gap between the walls and the crate is 100-150 mm, but each case should be treated individually. The wooden crate should be installed on dry days, as even the initially dried wood can easily be saturated with moisture.

DIY trim

The starting lines of the siding are separated by a gap of 1-1.2 cm. It is impossible to rest the profiles against the nail strips and against each other. If such an emphasis is placed, the thermal expansion of the overheated siding can arch it. It should be noted that self-installation of panels is much more profitable than the involvement of specialists. The fee for their services can reach 50 and even 60% of the cost of materials. Step-by-step instructions on siding layout can be found in many sources,but one cannot ignore the recommendations of the manufacturers. They advise to fix the vapor barrier layer below, then go the distance bars (the first crate). Above them put insulating material. The technology prescribes to put insulation in two layers, then put the second line of the sheathing. Only after that it's time to put the siding itself.

To do everything correctly, you will have to modify this approach and refine it. If the walls are insulated with mineral wool, it is necessary to form gaps for ventilation. Layers of thermal protection are laid out with the obligatory shift of the plates. In most cases, use polystyrene foam. Since the sunshine will not fall on the insulation, its finishing materials and plaster will not touch, you can choose the cheapest type of foam.

Before you mount the siding outside, you need to inspect the house and take a few measurements. Having found an unevenness with the help of long even rails and cords or tape measures, you can immediately eliminate the defect. The permissible deviation from the ideal straight line is 1.2 cm on a single plane or line. The difference between the diagonals of the openings of windows, doors should not exceed 0.6 cm.Installation of siding panels on inclined buildings, which generally retain the appearance of a rectangle, is allowed.

Then the right angles, horizontal lines in relation to the base and the ground are checked using level and plumb. Leaning over 2.5 cm in relation to the drawdown house sheathing can not be! After all, then it turns out that the building is in a critical, if not catastrophic, position. And even if it was possible to visually correct the surface of the facade by laying siding, it is still very soon the defects will return. They may even be aggravated, since it is still impossible to check the condition of the material under the decorative layer, but it will deteriorate.

If the crate is formed from rectangular planks or bars, they should be applied to the wall with a narrow edge. If deviations from the norm are no more than 0.3 cm, it is required to use single-level structures. The best option among them is considered a linear format. When deviations of walls from the norm vary from 0.3 to 0.6 cm, it is allowed to use a single-level wooden sheathing or a two-level structure made of metal, more precisely, from profile C.Violations of the plane of 6-12 mm require the use of either two wooden levels or a metal system.

In the first case, plywood linings are used at individual joints, in the second case, control strips. If you use a metal crate, a natural question arises about the insulation. It seems that there is no point in this, because the frame will let the cold through. But this problem is easily solved when the profile in the place of attachment to the walls or under the adjusting strips is enclosed with paronit gaskets or basalt cardboard. The same materials help to correct lags, to make them smoother.

To exclude the occurrence of a cold bridge in the body of the screw can be, if you do not introduce it directly into the wall, but first in a plastic plug. It is recommended to use self-tapping screws, which have a diameter of 0.4 to 0.6 cm and at the same time are introduced into the construction at least 6 cm. The best self-tapping screws are covered with a layer of phosphates (they are painted black), they are not subject to rust. To vary the mounting step from 35 to 50 cm is necessary, given the intensity of the winds. If at the bottom there is a holistic wooden lining of the old sample, it will be useful as a good underlying surface.

Particular attention should be paid to the design of the gable siding. Finishing of this part of the house is made mostly with vinyl elements. But we have to take into account that even exceptionally high-quality PVC panels can burst under the influence of extreme cold. It is necessary to carefully evaluate all sizes, since by making the panel too short, the defect cannot be fixed. The height of the gable is measured in the gaps between the grooves.

It is easiest to assess the vertical gaps from thermal expansion by locking a pair of panels into the lock. When the roof has different slopes, it is required to form a couple of templates, and according to them prepare special profiles. Finishing gable recommended to do with scaffolding. It is safer and more convenient than using a ladder. It is recommended to design and install finishing material after the construction of the roof; then you need to work on the corners and the eaves.

Tips

The choice of siding for the walls of a country house or a country house can not be limited to a simple determination of the appropriate type. It is required to check whether the color of the material is uniform. After all, high-quality material is uniform in appearance from the inside and outside. Low cost designs can be lighter inside than outside.The reason is simple: pigment is the most expensive substance in siding recipes.

The thickness of the panels on all parts must be strictly the same. If a difference occurs, the behavior of the structure can become unpredictable, it deforms very quickly. When the size distortion is clearly noticeable even without measurements, it is better not to buy such material. It is extremely important to check the holes with which the nails are fastened or the screws in the upper parts of the panels. Such openings should be perfectly even and mutually the same. If the edge is not too smooth, this indicates a violation of technology.

A look at the front surface will also tell a lot to experts and connoisseurs. The quality product is covered with a matte layer, the gloss for vinyl siding is undesirable. The product of optimum quality is packaged as it should, for this purpose they use strong cardboard boxes. Polyethylene is more economical, but in it panels can collapse under their own weight or under careless exposure. Ductility should be high. Having bent a site about a nailing edge, it is possible to estimate it at once: the bad siding at the same time will break.

Installation of the profile is made in 0.5 m increments; To fix it to the wall, apply suspensions. This practice minimizes the differences in surface relief and helps to fasten elements strictly at a certain level.

The technology prohibits the use of crates for the formation of:

- layered (exfoliating) material;

- deformed blocks;

- wood with blue spots, with rot and knots through.

Profiles are required to dock on the same level on either side of the house. Instead of the angular profile, you can mount two starting blocks in the shape of a letter J. But this can be done only if the wall has been waterproofed with preliminary waterproofing of the wall. Otherwise, its tightness will be questionable. It is required to leave a gap of 0.3 cm from the profile to the soffit, and the lowest edge of the profiles should go further than the bar J by 6 mm.

Fasteners must be driven or screwed strictly into the centers of the prepared holes. Even the metal should not press the cap too hard. Then thermal deformation will not cause negative manifestations. Fastening is made at the left and below. It is strictly forbidden to pierce with fasteners any places that are not designed for this purpose.

Facing the log of any materials, including siding, can be made only after the completion of shrinkage, that is, when will pass at least ½ year upon completion of construction. Otherwise, the tree will sit chaotically pull the entire decoration. It is not recommended to paint the siding outside, it can disturb the quality of the construction. If you do not have much experience doing the work yourself, it is better to seek the help of professionals. A noticeable increase in the cost of the lining is justified when an independent installation cannot be done qualitatively.

Beautiful examples

There are many ways to beautifully perform installation siding. Horizontally oriented panels (moderately light) will not get dirty and at the same time create a pleasant appearance. The arrangement of the windows on the facade, decorated in this way, can be quite intricate - the construction will not become worse. Stylish metal siding looks luxurious and solemn, but at the same time quite calm. The imitation of the beam shown in the photo turns out to be quite plausible and in harmony with the color of the perimeter of the window openings.

Even a much lighter tone of siding on the pediment is not perceived in an alien way,it becomes an original and fresh contrast. And here a completely different approach is demonstrated. Designers preferred to use perfectly smooth panels of delectable chocolate color. The texture of various natural wood bottom is replaced by a brickwork base. The lower part of the roof ledge and the drainpipe are painted albeit in a different color, but still there is strict harmony between them, the exterior is laconic in appearance.

Review the installation of vinyl siding, see the following video.