Vinyl siding: features and benefits

Vinyl siding is very popular. What caused the high consumer demand for it and what technical and operational properties it possesses, we will tell in this article.

Special features

Vinyl is a type of siding based on polyvinyl chloride. It is used for exterior cladding of buildings, it has rather high technical and operational characteristics. Available in color (matt and glossy multi-colored panels), and can also imitate brick, stone, wood.

Vinyl siding is 80% polyvinyl chloride, and also includes 6 trace elements. However, it is the quality of PVC that largely determines the quality of the finished product.

In some cases, it is acceptable to use up to 5% recycled polyvinyl chloride in the lower layers of the sheet, but this degrades the properties and strength of the material.

To fill the structure of the panel in its lower layer is used calcium carbonate, the content of which can reach 15%. Titanium dioxide is added to the upper layer, which guarantees its stability and invariance of the outer coating, color. It is thanks to this component that the material is protected from the negative effects of sunlight. However, only if the content of titanium dioxide is not lower than 10%.

A small amount contains pigments, modifiers and butadiene. Also in the production of various lubricant components. They are not included in the siding, and are used to improve the slip of the material on the metal during its manufacture. With a lack of lubricating components, the siding surface will have defects, "burrs".

Vinyl siding is extruded. First, ground in PVC powder and other components are mixed, after which the semi-liquid mixture is pressed through a special hole and comes in the form of a tape.The latter is distinguished by its stability and, at the exit, is cut into strips of the desired dimensions, it is given the necessary look, a working profile.

At the same time, they single out the technology of mono-and co-extrusion. In the first case, all components are distributed in the thickness of the material evenly, without taking into account the external and internal environment of operation. The panels produced by the method of co-extrusion, have the outer and inner layer, bonded to each other at the molecular level. The outer layer contains additives that increase the moisture resistance and weather resistance of the material. This layer takes about 25% of the sheet thickness. The rest is the inner layer containing the components to increase the thermal efficiency and strength of the siding.

Advantages and disadvantages

Vinyl siding allows you to quickly transform the look of the house, create an individual design. At the same time, it has the smallest weight (metal and especially fiber cement analogues are much heavier), so there is no need to additionally strengthen the walls and the foundation of the building, which helps reduce construction costs. Due to the low weight of plastic siding, it is possible to optimize transportation costs and reduce the labor intensity of installation (the panels can be fixed even alone).

Finally, the low weight allows it to be fixed to different types of walls - these can be either light wood and frame structures, or heavier foam block houses, for example. In addition, plastic siding can even sheathe old buildings.

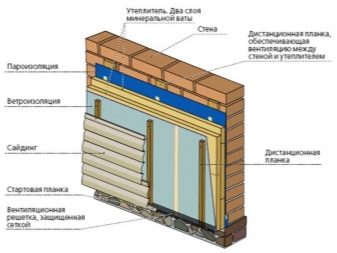

The quality of the walls is also not high. Minor defects, defects, differences in height and roughness need not be removed, since the siding (any, metal siding including) is mounted on the crate. By the way, a similar installation system allows you to hide a layer of insulation of the required thickness under the panels. Simultaneous external insulation and lining save time and get the most from the point of ergonomics and thermal efficiency result.

As a rule, the technology of ventilated cladding is used when covering with siding, when a ventilation gap of 3-5 cm is left between the layer of insulation and wall panels. It gives an additional insulating effect and gives additional ventilation for walls and insulation.

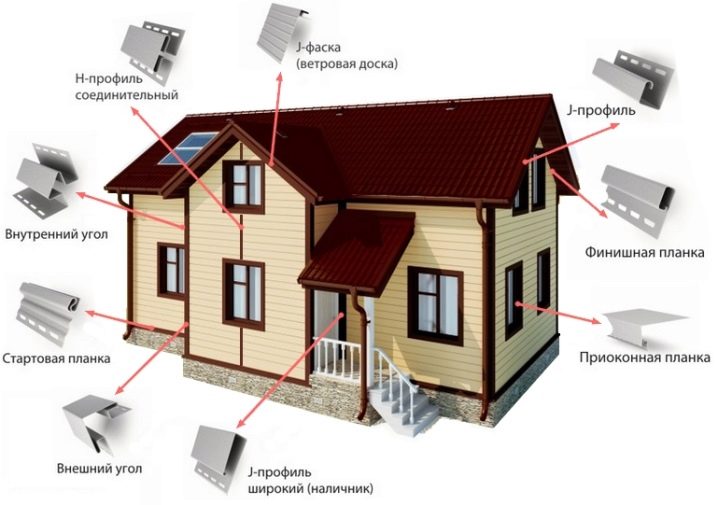

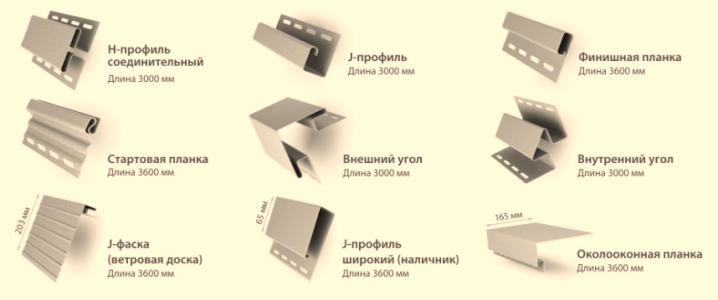

Installation of siding is quite simple and is carried out with the help of special elements.This eliminates the cost of buying or preparing a concrete solution, and also makes installation possible in almost any weather.

Fastening material resembles the assembly of the children's designer and can be performed even by an unprofessional builder. The panels can be cut with a conventional grinder or cutter; special equipment is not required. Thanks to a special locking mechanism, not only the installation process is facilitated, but also the hermetic joining of profiles is ensured, its resistance to strong, even hurricane, winds.

PVC-based siding is not afraid of moisture, and due to the addition of special modifiers, it demonstrates resistance to the effects of low temperatures and aggressive UV rays. Lowering the temperature somewhat reduces the strength of polyvinyl chloride (however, this is typical of many materials), but does not lead to its degradation. Durable and weather-resistant vinyl siding at the same time has a low density (1.35-1.43 g / m3).

The material is not susceptible to corrosion (in contrast to cheap options for metal siding), it is biostable.Another advantage of vinyl panels is their inability to conduct electricity, in other words, they are dielectrics.

It is vinyl siding that shows the greatest number of color options. If you need a panel of unusual colors, it is better to immediately begin to study the catalog of plastic siding. In addition, the material is produced, imitating wood, stone and brick surfaces.

Vinyl siding compared to other types has a lower cost. However, in its strength, it is inferior to analogues of metal and fiber cement. Of course, PVC products exhibit decent strength and resistance to mechanical stress, but with a strong blow, plastic, unlike metal and fiber cement, may crack or be broken.

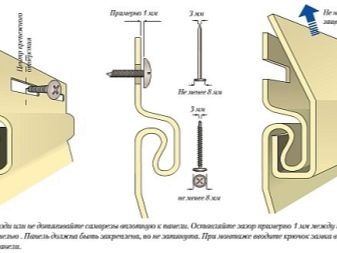

In addition, the material tends to shrink and expand under the influence of high and low temperatures. This feature cannot be called a minus; rather, it is a feature that should be taken into account during installation. Installation of panels should be carried out with a small gap in order to avoid deformation during thermal expansion.

Types and characteristics

A kind of vinyl siding is acrylic, which shows higher performance. It has greater strength and shock resistance, withstands more active UV exposure and a heating temperature of up to + 85 ° C.

Depending on the purpose, there are the following types of vinyl siding:

Wall

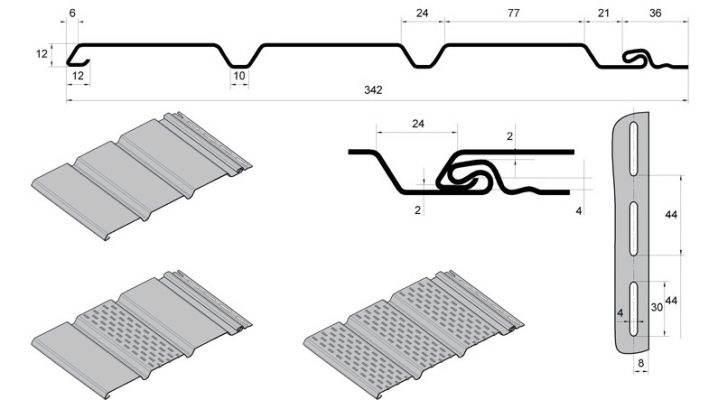

Used for cladding exterior walls. Front panels are presented in the following varieties: ship board (imitates timber), "herringbone" (can be single, double and triple), block house (imitates a log surface), wall paneling.

Ground floor

Siding designed for plating the basement of the house. It differs from the wall thicker and more compact in size (it has the form of rectangles, the height of which corresponds to the standard height of the base). Differs in the increased durability to mechanical influences, moisture resistance and resistance to freezing, heaving of soil, is chemically inert.

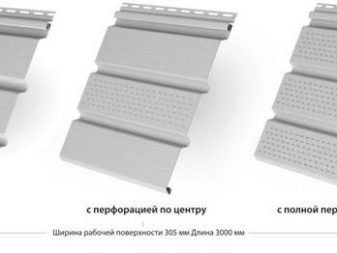

Spotlights

Special panels used for lining horizontal surfaces, usually for filing eaves of the eaves. There are solid and fully perforated, as well as having a perforation only in the central part.Due to the perforation of the facade receives additional ventilation.

A single GOST, which determines the dimensions of vinyl siding, is absent, so each manufacturer offers a proprietary dimensional grid. In general, the length of vinyl standard siding is 2.5-4 m, width is 20-30 cm, thickness - 1-1.2 mm.

The differences between the panels relate to and colors - highlight bright neutral shades and darker and brighter colors, as well as panels with a glossy and matte surface.

Contrary to popular belief, PVC does not support burningthat is, if you stop the action of the fire, then the burning will immediately stop (when you make fires or the neighboring buildings ignite, PVC siding does not burn). Of course, the fire hazard of vinyl siding is higher than similar values of metal siding and fiber cement panels, the flammability of which is the class NG (non-combustible).

The ignition temperature of the material is 500 degrees. However, when heated to 100 degrees, it begins to release hydrogen chloride, or hydrochloric acid (does not apply to acrylic siding, which even when heated remains non-toxic).

Colors and design

Vinyl siding is an option that shows lots of colors. The main volume of the market is the material of soothing pastel and light shades - pink, beige, light green, light gray, light brown, etc. They are obtained by interfering with the necessary pigment in the white composition. Somewhat different technology produces panels of bright hues - red, rich blue, cherry, orange, etc. They are presented in a slightly smaller volume, because they do not enjoy such high popularity as quieter shades.

Initially, vinyl siding is matte (this is required by the production features), glossing requires additional operations. Bright panels usually have a shiny surface.

Separately, it is necessary to select a material that imitates the surfaces of various types of wood, stone or brickwork. Thanks to modern technological advances, imitation is obtained as accurate as possible - it can only be determined on closer examination.

As for the picture, the vinyl panels are already described “herringbone”which may include 1-3 “waves”, a “ship board” pattern and a block house.The single and double herringbone and shipboard boards are the most common siding in Russia, and block house has become increasingly popular lately.

Manufacturer Overview

Positive feedback is received by such companies:

- Mitten. A brand with more than 50 years of history. Production is carried out exclusively in Canada, which ensures the highest quality products and their compliance with the highest standards. The company gives a 50-year warranty on its products. The disadvantage is a very high cost.

- Royal. Another Canadian manufacturer that manufactures siding using a unique technology (there are patents confirming this). Lead and heavy metals are missing from the material. The best option for operation in harsh climatic conditions, since it is possible under the condition of + 50 ... -50 degrees. Manufacturer's warranty - 50 years.

- Boryszew. Polish products, demonstrating a decent combination of price and quality, belong to the average price range.

- Slovinyl Siding. A distinctive feature of this material from Slovenia is its increased impact resistance, including at low temperatures, compared to its counterparts in its price range. It is characterized by high quality, which is confirmed by the ISO 14001 certificate.

- Alta Profile. One of the domestic leaders, the leading activity of which is the production of vinyl siding. A distinctive feature of the material is an anti-uraganic lock. Manufacturer's warranty - 30 years. Respect and popularity among the owners of this brand has won a harmonious combination of price and quality of its products.

- Fineber. Products of domestic manufacturers, the most adapted for use in the Russian climate. It is made by a coextrusion method, has a guarantee from the manufacturer of 25 years. Available in pastel and rich colors, there are also collections that mimic woody surfaces.

- Grand Line. Another domestic company that produces vinyl siding. The basis of production is the production of panels imitating wooden surfaces. There is a special ruler, suitable for installation at -10 (characterized by greater flexibility and weather resistance). Resistance to UV rays without changing the aesthetic properties of the material - 9 years, manufacturer's warranty - 50 years.

How to choose?

For a long time it was believed that American and European siding has a higher quality than domestic.This was due to the fact that in Russia there are no uniform requirements and standards for the production of siding. The last statement is true, but today more and more leading domestic firms are working on accepted European standards.

This means that their products are not inferior in quality and safety of imported, but at the same time has a lower cost (savings on customs duties, transportation). For example, the American ASTM standard concerns siding thickness. The minimum figures are 0.9-1.2 mm. A material intended to be used for about 10 years should be 1.1 mm thick.

Attention should be paid to the material's compliance with ASTM D 4226 and ASTM D 256. They regulate the strength of siding according to various criteria. The safety of the composition is determined by ASTM D 1784-81.

For compliance with the stated standards should be checked first of all products of Canadian, German origin. If the material is labeled as "Gray-back", then this means that up to 5% of its composition is made from recycled PVC. It will cost slightly lower than its counterpart, where secondary PVC is not used, but it will also be inferior in quality.

When operating in conditions of elevated temperatures and active UV exposure, it is better to choose acrylic siding. For covering the basement of the building should choose a more durable basement siding. Its thickness should be at least 3-4 cm.

As a rule, siding of saturated or dark tones is more expensive, due to the fact that the top layer contains more expensive chemicals to protect against UV rays. Affordable titanium dioxide in combination with dark or bright pigments simply does not work.

The result of the photodestruction process (burnout, the appearance of whitish spots) is almost imperceptible on panels of light shades. Acrylic material is more resistant to UV rays, so it is better to buy acrylic panels for bright and dark panels.

If it is assumed that the surface of the siding will often be washed using chemicals, then it is better to choose acrylic siding. Vinyl can only be washed with clean water, directing it, for example, from a garden hose.

When buying should be understood that the name "acrylic siding" is very conditional. The panels can not be 100% acrylic, otherwise they will cost a great deal dear, and it is not necessary for the quality of the product.Even such famous Mitten, Tecos on their official sites say that their vinyl siding contains a certain amount of acrylic to increase the thickness of the panel and stabilize the color.

If the seller tries to explain the unreasonably high cost of the panels from “100% acrylic”, then this is either a dishonest seller or a layman in his own business.

How to calculate the amount of material?

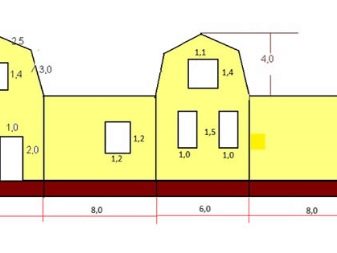

To calculate the required amount of materials, it is required to compile a drawing of the object with exact data of the width and height of its facade. In this case, the calculations should be carried out taking into account the size of the installed crates. In general, to find out the amount of material, multiply the length and width of all sides of the facade and add up the results. Get the total area of the house. Now from it it is necessary to calculate the area of areas that are not subject to plating. These are window and doorways.

The remaining result should be divided by the width of the panel (if the siding height corresponds to the height of the building). The result will be the total number of panels that are required for finishing. When receiving a fractional number it is rounded up. Now it remains to find out how many panels are in one package in order to establish the required number of packages.

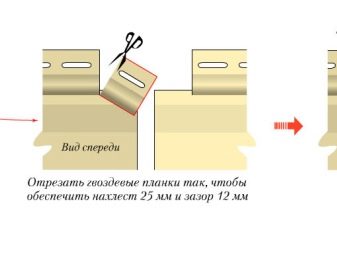

We must not forget that in some parts of the panel it is necessary to cut, in addition, you should take care of a small stock of material in case of marriage or damage.

The stock is usually 7-10% of the total number of panels for houses of simple configuration and 15% for objects with many complex architectural elements.

Another option to calculate the number of panels is to draw all parts of the facade in certain proportions on a sheet of paper. Next, you need to cut out of paper sheets siding in the same proportions. The dimensions of the paper "panels" should correspond (in a reduced form, of course) to the dimensions of the material that you plan to purchase. "Siding" of paper is superimposed on the drawings, if necessary, cut off. This method of calculation is good because it minimizes the amount of waste.

Finally, to calculate the amount of siding, you can use special online calculators, which can be found on the website of manufacturers or large building stores.

When choosing a herringbone wall panel, the calculation of the required amount should be made taking into account which (single, double or triple) herringbone is used.The single is indicated by the letter “S”, the double “D”, triple - “T”, so if the siding is marked as “D” is 4.5 inches, this means that the width of one “wave” is 4.5 inches or 114.3 mm . Since there are two such “waves”, the width of the entire panel is 228.6 mm.

User's manual

Installation of vinyl siding is not recommended to conduct at temperatures below 12 degrees. Before installation, the panels should rest in outdoor conditions for about 2 hours. When installing, you should remember about the coefficient of expansion of the material, so the panels are fixed with a gap of 5-7 mm. If it is necessary to perform works at temperatures below +12 (not recommended, but possible), a gap of 10 mm is left between the panels.

Special preparation of the facade is not required. If necessary, you can remove the past coating, cut off pipes and wires, reinforce the crumbling areas. Next to the surface of the wall on the brackets attached crate, should begin with the installation of the starting bar. On how smoothly and precisely it will be fixed, depends on the accuracy of laying and the absence of gaps and distortions between the wall panels.

After the starting bar, the rest of the batten profiles are mounted, wall panels are hung on them. Experts advise after stacking every 4-5 rows to verify their level.Tolerance from the level should not exceed 2%.

Screws need to be screwed strictly perpendicularly and it should be done through special holes. It is forbidden to directly nail the fasteners, it will lead to cracking of the material. There should be a small distance between the cap of the screw and the surface (approximately equal to the thickness of the coin). You need to fasten the screws first from above, so that the panel hangs like on the first screws, while you are screwing down the lower fasteners.

For the design of corners it is better to use special additional elements. In this case, first install the corner element, and then for him wind up and fix the wall panel. Complex architectural elements, as well as window and other openings, are also designed with special additional elements, the overhangs of the roof are hemmed with soffits.

If it is intended to warm the facade, then after installing the batten between its profiles, a heater is laid - extruded polystyrene foam or stone wool.

It is important to prevent the formation of gaps between the profile of the batten and the layer of insulation, since in the future they will turn into “cold bridges”.

A windproof membrane is laid on top of the insulation, its installation is overlapped, the joints are glued with tape. Further, this layer is closed by wall panels according to the technology described above. There is a small space between the siding and the insulation layer.

The crate can be made of galvanized metal profiles or wooden logs. The latter are suitable for wooden buildings, but have a shorter service life. In any case, if you prepare the subsystem with your own hands, the surface of the lag for it should be treated with anti-corrosion compounds and antiseptics.

Beautiful examples

When choosing a model and shade of siding should take into account the overall style of the exterior, the design of the nearest buildings, and ideally - the internal design. Agree, the house is trimmed somewhat disharmoniously, sheathed outside by a block house, the internal design of which is made in a loft-style, for example.

- Traditionally for paneling use light panels, selecting for them a socle siding under a stone or timber. Avoid boredom and monotony allows a combination of 2-3 close in color pastel shades.

- It looks good when the exterior is combined with a shade of the roof.As a rule, the tone of the roof is chosen darker, the same shade can be used as an additional on the walls. When using the roof is lighter than the walls, there is a risk of getting the effect of visual incompleteness.

- All siding types that mimic finishing materials are harmoniously combined with each other. Win-win, of course, is a combination of brickwork and stone. The object is instantly transformed, acquires status and respectability, noble monumentality.

- The use of white or, on the contrary, several types of bright color siding, allows you to recreate a cozy atmosphere of country style. It is appropriate for small houses, including summer houses.

- Using even one shade of siding, you can add bulk to the structure and make it original. To do this, you just need to combine the siding, fixed in the horizontal and vertical direction.

- Siding block house is suitable not only for traditional houses in the Russian style. If you add it to large (including panoramic) windows, as well as to use non-traditional (brown) shades of the panels, you can get a very modern solution in terms of style.

- The house, trimmed with dark panels, looks stylish and elegant. Wide snow-white platbands, and also bright accent in the form of a red entrance door, allow to avoid gloom.

For how to choose vinyl siding, see the next video.