Wood fillers: types and features of the application

Wood products and wood coatings need proper processing. Putty wood is used in order to increase their operational life, increase strength, resistance to moisture and heat. This article will discuss the characteristic features of putty, its varieties, methods of making their own hands and much more.

Special features

Functions of wood putty are varied. The qualitative composition has high decorative properties, and can also effectively seal the existing cracks in the floor and walls. Also, putty can eliminate bumps and other defects.

High-quality putty should meet a fairly large list of requirements, however, we consider only some of them:

- Base adhesion should be high.

- The mixture should have a uniform appearance.

- In the putty should be no mechanical additives and impurities, since this can create certain difficulties during installation.

- A minimum level of shrinkage is required, since in this case the mixture can be applied only in one layer, which will save money.

- After the putty dries, it should not crumble and crack.

- Easy grinding.

- Apply the mixture should be easy, and the drying time should be minimal.

Spackling compounds can be made for various purposes, they differ in the method of production, composition, color and method of application. To make the right choice, you need to understand the varieties of this product.

It is worth using wood putty because:

- it prevents the moisture from absorbing wood, therefore it will remain dry, which will affect its service life;

- using a quality mixture, it is possible to smooth out existing knots and cracks, to mask defects, this is extremely necessary, since there is no tree that does not have any flaws;

- You should not worry about the color of the putty, because there are species that become transparent when dried and emphasize the unique texture of the wood.

Kinds

Hard putty on wood is mainly used to hide existing defects in wood. The market of building materials can please you with a large variety of these mixtures, however, this very fact makes it difficult to choose. To better understand what kind of putty to choose, you need to familiarize yourself with each type of mixture in more detail.

- Putty on solvent. The basis of this mixture is the solvent. This type is very popular not only among joinery lovers, but also among professionals involved in mass woodworking. The presented type is the very first, since the subsequent versions were developed during the experiments on the basic composition and during its operation. The main advantage of this material is high strength. It is important to note that it is necessary to work with this putty extremely carefully, since it has an unpleasant smell and is characterized by an unsafe chemical composition.Working with her, be sure to follow all safety rules.

- Water-based blends. Unlike the previous version, this type is characterized by complete safety. Use the mixture as simple as possible, the material is elastic. To remove excess, there is no need for acetone or turpentine, because you can use a regular rag. The presented product is characterized by a long drying time in the tank, due to which the shelf life becomes longer, and you do not need to rush in order to finish the room. Adhesion level is also high. The mixture is wonderfully applied to the polished surface.

This putty is characterized by a rich list of advantages:

- High efficiency, since it is capable of qualitatively covering up all sorts of defects and irregularities. It can be used for putty joints floorboards.

- Environmentally friendly, as it does not have in the composition of harmful substances.

- Long service life and high moisture resistance, which is manifested in the ability to withstand various weather conditions.

- Resistance to temperature fluctuations, which determines the security of wood from fire,if it was plastered.

- The elasticity allowing to model various invoices.

It is important to note that many of the properties presented will appear only after the mixture has completely dried and hardened, and it is important to take into account the rules for applying the material.

- Oil puttythat focus on exterior trim. Made this mixture on the basis of oil and solvents. The presented material is ideal for finishing the surface for painting. After the putty is applied and dry, you get a reliable waterproof coating that will not be afraid of the effects of external aggressors. It is important to note that another putty with the exterior finish will soon begin to crumble and crack. This type of material can be purchased in containers weighing from 0.5 to 15 kilograms, so you can choose packaging, depending on the amount of work.

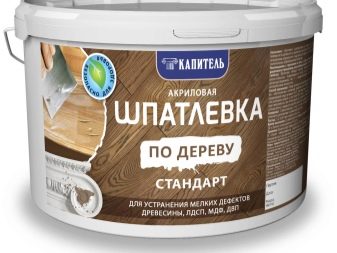

- Polymer (acrylic) compoundsvery popular. Characterized by this type of mixture of excellent performance properties. It has a long service life, excellent elasticity and does not shrink. It can be used for dry and damp rooms.

Special features of the polymer material are:

- High elasticity, allowing the mixture to fill even the smallest cracks and crevices.

- Lack of shrinkage thanks to what in order to process a surface, only 1 layer is required.

- Long service life, which can vary from 3 to 10 years, depending on certain conditions.

- The cost, which is significantly lower than the cost of putty on oil or water base.

- A rich palette of colors.

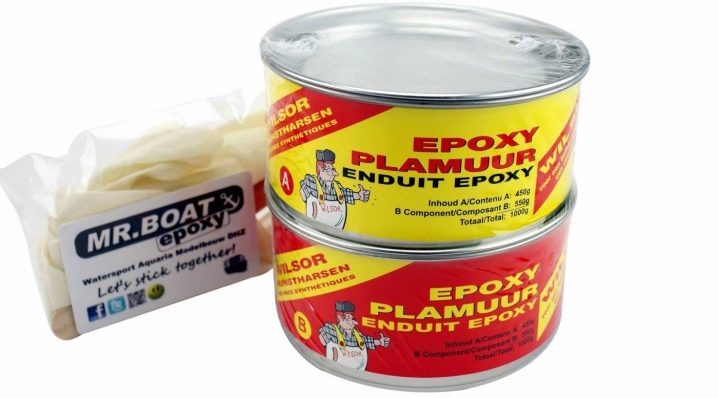

- Epoxy puttywhich purpose is repair of wooden surfaces. It will be required in cases where a wooden door, window frame, pillars, or other design in need of major repairs. After hardening, it exhibits high strength and reliability. The mixture does not have any odor and does not shrink during drying. The surface to be treated with the material in question is resistant to moisture and chemical solvents. The disadvantages of this type include the fact that it is not allowed to apply stain to the layer of putty.

Less popular types:

- Nitroshpaklevka consisting of products of cellulose origin.

- Gypsum mixture, which is practically not used today, as it requires application to the entire surface, and not to the problem area. Professionals in the construction industry have long given their preference to other types of putty, but amateurs still use gypsum putty because of its low cost.

- Mix for a tree under painting. This material does not mask defects, but is used for better paint application.

This putty is also divided into the following types:

- heat and moisture resistant;

- elastic;

- alkyd;

- quick-drying;

- latex, etc.

Making your own hands

If you decide to purchase a putty for surface finishing, then with a large amount of work you will need to spend a significant amount of money. However, not every mixture can please you with its quality, so you risk wasting money. You can make the putty mixture yourself using simple and cheap materials. The resulting solution will be characterized by excellent durability and reliability, while the cost of its manufacture will be minimal. Consider 3 ways to prepare putty with your own hands:

PVA glue and ordinary chalk

Prepared as follows:

- crushed chalk is diluted in glue (it is necessary to achieve a homogeneous state, the visually obtained solution should resemble sour cream);

- in order to seal cracks and pits, it is necessary to add a small amount of sawdust or wood dust to the mixture;

- dry the solution will be no more than a day.

Chalk and water soluble lacquer

Putty, for which you need to buy chalk and water-soluble varnish. It should be done similarly to the first version.

To make the composition as strong and reliable as possible, follow the further instructions:

- it is best to mix the solution in the evening, and apply in the morning;

- mixing the varnish with chalk, you should get a consistency, visually reminiscent of toothpaste;

- if you have a mixture that is too thick, you can remedy the situation by adding a small amount of water;

- Such a homemade putty dries in about 12 hours.

Lacquer is a plastic and malleable material, so try not to miss the moment when the solution will have a uniform composition, resembling a paste. In this case, you can also add sawdust or wood dust to the mixture in order to mask the cracks and holes that are large in size.

The most difficult recipe of cooking, where you need to combine 60 grams of turpentine and 280 grams of linseed oil with 30 grams of pumice, which is added 300 grams of water. Stir the solution thoroughly until a homogeneous composition, where then it is necessary to pour 20 grams of casein and gelatin, 12 grams of borax and 18 grams of 18% ammonia. Put the resulting mass in a water bath, not forgetting to stir. You should get a homogeneous mixture that looks like a toothpaste. After the composition is cooled, it can be used to finish a wooden surface.

Having decided to make wood putty yourself, you can be sure of its quality and reliability. Remember that how it will be strong and durable, depends only on you. High-quality work will allow you to get a quality result.

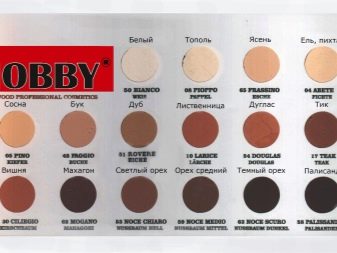

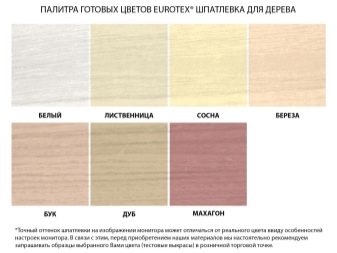

Colors

The modern building materials market is ready to please you with a variety of different types of wood fillers, which differ not only in their use and composition, but also in color. It is important to note that the manufacturers of the mixtures in question seek to satisfy the various desires of customers, therefore, they are rapidly expanding the range of colors.Today you can choose different shades of wood, depending on what kind of wood you need to process. The most common are shades of oak, ash, pine, cherry and walnut. Transparent blends are in particular demand.

Today, white and colored putties are quite popular, as well as a mixture of wenge color. As a decor, it is used very often.

Scope of application

Wood putty is used for processing or restoration of various surfaces. It can be used to finish the lining of MDF panels or plywood, be used in the preparation of parquet for further painting. The mixture is actively used to restore the door leafs, window frames or the old flooring. These are the most common use cases, but this list can be expanded, because the tool is quite universal.

It is important to note what properties the surface putty transmits in order to understand why it should be used at all:

- The moisture resistance of wood increases significantly, which favorably affects the service life.

- Regardless of which type of putty you choose, it can be used to mask existing defects, with some compositions able to cope with very large injuries.

- Using putty, you can emphasize the texture of wood.

- The surface that has been treated with the material in question can be boldly painted or coated with a decorative layer of varnish.

- The putty used for finishing the flooring is characterized by an excellent adhesion to the surface. It perfectly fills the existing irregularities and even the smallest cracks that are sure to appear on the floor after several years of operation.

The mixture is suitable not only for decoration, but also for embedding deep cracks, leveling walls, exterior works. With its help, you can make any errors invisible, putty walls, etc. This is a universal building composition, which is also used in the furniture industry.

Manufacturers

Coming to the store building materials, you will encounter a rich choice of putty mixture for wood. On the shelves you can see the different varieties of putty from different manufacturers.It is important to note that there are quite a lot of companies involved in the production of the material in question. You can purchase a putty from both domestic and foreign manufacturers.

Consider the most popular brands:

- Finnish company TikkurilaFor many years engaged in the production of various putty mixtures and types of paints. The disadvantage of the manufacturer is a relatively high cost, which is justified by high quality products. The presented mixtures have a feature of imitating wood color, while they are characterized by amazing adhesion with the surface. Putty from Tikkurila can be used in various conditions, even in rooms with high humidity.

- Lacra - a manufacturer that has established itself from the excellent side. Its putty is characterized by high quality. Can be purchased for various types of flooring.

- VGT produces putty mixture for painting. This company produces a mixture that has a uniform structure, while the color palette is quite wide.

- Eurotex different quality composition, while the cost of the products is relatively low.

- "Tex" - the leader of the domestic market, offers an affordable product, featuring high quality workmanship.

It is important to note that the range of mixtures is much wider than what is presented above. Large variety makes it difficult to choose the material. Next, we will talk about what criteria to rely on when choosing a putty mixture.

Also among the well-known manufacturers can distinguish brands:

- "Extra";

- Parade;

- "Rainbow";

- Smes;

- "Olympus";

- Spakkeli Puukitti, etc.

Tips for choosing

The most common types of putty are mixtures made of water-based or solvent. The first option is ideal for domestic use, since the second is highly toxic and is purchased mainly for industrial production. Naturally, if you provide all the security measures and use the mixture carefully, then you can use this putty for finishing the house.

Solvent-based blends are characterized in that:

- have a rich palette of colors with different shades;

- have high adhesion and dry relatively quickly;

- differ in resistance to sharp temperature differences.

It should be noted that water fillers also have these advantages, so be based on personal preferences, given that the list of varieties of the material in question is quite large.

The wooden surface, after it is processed with the help of putty, should be almost perfect. For example, processing the wall under the wallpaper, you can tolerate the presence of any grains or grooves, however, if we are talking about painting or applying varnish, it is important to responsibly approach the choice of putty material.

In order not to make a mistake in choosing, we recommend that you pay special attention to the following parameters:

- good elasticity, thanks to which it is quite simple to apply the mixture, while it can disguise even the smallest defects;

- drying time should be minimal, in order not to delay the repair, but rather to start further actions;

- choosing a dry mixture, stop your choice on fine formulations, thus, putty will allow you to get a smooth and thin layer without any lumps;

- priority should be given to the type of material that will be safe for human health.

If you are in doubt about your choice, then in any situation you can do the independent production of the mixture. So you can be sure of the quality of the mixture and at the same time save money. If you absolutely do not want to make a mixture with your own hands, then you need to stop your choice on the manufacturer, which is time-tested. Learn the main characteristics of a particular putty brand, and also pay attention to customer reviews.

How to fix a marriage on wooden products using putty, see the next video.