Putty Knauf Fugen: the pros and cons

German quality is always based on the desire to achieve the desired result, on painstaking work and love for their work. The brand Knauf has repeatedly proved to its adherents all its power and qualitative approach to business.

One of the building mixes that the Germans can be proud of is the Knauf Fugen putty.

Special features

The plaster universal putty Knauf Fugen had earlier a longer name - Fugenfuller. This is a classic plaster-based putty, which is firmly entrenched in the global market for dry construction mixes.

The main feature of this material is a guarantee of success at any effort, subject to unconditional following instructions:

- Observe the temperature of the room and humidity. So, in a room where surfaces will be treated with Knauf Fugen putty, there should be no more than +10 degrees Celsius.And the humidity should not exceed the standard rates of 70-80%.

- Pre-treat the surfaces with a primer, clean and dry them.

- Tools for work should always be clean, otherwise the mixture risks acquiring a heterogeneous structure and, as a result, will not satisfy your requirements.

It should also be remembered that this type of putty is not suitable for large-scale projects. To lay it evenly, it must be applied in a thin layer, not more than three millimeters.

Gypsum base mix does not allow long to use a large amount of putty. It dries very quickly, so it is recommended to dilute the mixture in small quantities..

Thanks to its ground structure, Fugen can be used as a finishing layer. before applying paint, sticking wallpaper, etc. Of course, one layer can not do, because, like any other gypsum plaster, it is sure to shrink.

Many users have noted the difficulties that they face in the process of surface treatment Knauf Fugen. It is advised to resort to less whimsical counterparts, which are inferior to the German manufacturer, not only in price, but also in quality.And, therefore, in the final result.

In general, Knauf Fugen putties have positive reviews, but there are not very pleasant words about a professional product.

Advantages and disadvantages

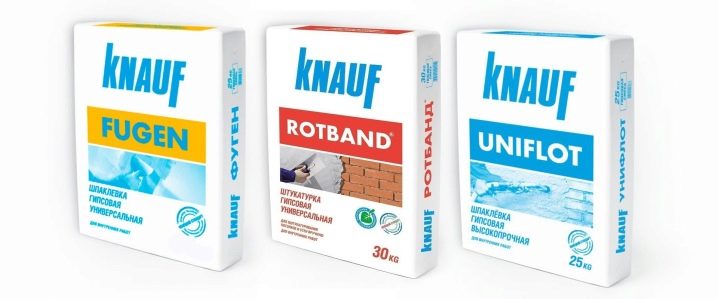

Since there are three main types of Knauf Fugen putty, the manufacturer on its official website indicates not only the general advantages of this wonderful material, but also individual for each type:

- Knauf fugen - for processing the faces of the GCR compound, does not crack after drying, the putty is made from an eco-friendly, pure natural material - gypsum.

- Knauf Fugen GF - for continuous filling of gypsum fiber liners, sealing joints and elements of the floor Knauf. Differs in high strength and elasticity, lack of cracks on the treated dried surface. HB is the same gypsum, but with polymeric additives that do not adversely affect the human body.

- Knauf Fugen Hydro - moisture resistant putty from plaster for processing joints of GKLV and mounting of gypsum boards, the fastening of which is called tongue-and-groove. The product gives the minimum shrinkage, does not crack, is maximum resistant to moisture, as it contains eco-friendly polymer and hydrophobic additives.

Even with professional mixes, it is not without drawbacks and flaws.Among the most serious and constantly encountered: quick drying in the tank for mixing, inconvenience associated with grinding, the possibility of applying only a thin layer.

The universality of Knauf Fugen putty is at hand only for those who are ready to use it as an additional means for preliminary processing. As an independent finishing material, it is not suitable enough..

Specifications

In order to accurately calculate the amount of proper dry mix, you should be familiar with the main characteristics of the material used.

Technical characteristics consist in the description of features of cultivation and laying of putty on a surface:

- excellent fine-grained structure characterizing the material as a good finishing layer. The maximum grain diameter is 0.15 mm;

- the thickness of the layer varies from one to three millimeters, which allows the use of putty as an invisible basic base;

- from one kilogram of dry mix, one liter of three hundred grams of the solution prepared for use is obtained;

- the prepared mixture can be used for no more than half an hour until it is completely dried in the mixing tank;

- The shelf life of the dry mix is 6 months.

The components of the Knauf Fugen multipurpose gypsum mix create a high-strength base for the subsequent processing of planes. The Hydro variety often acts as a starting putty., because its physical characteristics allow its use in wet areas. It protects the walls from mold, mildew and parasites.

Customer feedback on the technical characteristics specified by the manufacturer, note that everything is true. Due to the large amount of information and its properties, the putty gains prestige in the eyes of both professionals and beginners who have resorted to this method of interior finishing for the first time.

A dry mix is paper bags weighing 5, 10, and 25 kilograms. They must be stored in cool, dry, frost-free rooms on a wooden backing. If a bag breakthrough is detected, this putty should be used first., but only if it does not get wet and does not stick together. Re-use of wet putty is impossible.

The instructions for use of plaster-based Knauf putty explains how to properly dilute and use the mixture with maximum efficiency.Also there is indicated the approximate consumption of putty, depending on its purpose.

Consumption

First of all, the amount of putty will depend on what work it is planned to perform. And also an important factor is the surface on which Knauf Fugen will be applied. If you just need to seal the drywall seams, you need 250 g per square meter of coverage. Solid filling of walls with a layer up to 1 mm may require from 800 g to 1 kg per 1 m2.

Knauf Fugen GF has a slight difference from the previous type of putty in terms of expenditure, since the coating thickness here can already increase to 5 mm:

- up to 600 grams of the finished mixture can be used for processing and coating joints and seams;

- when applied to a solid wall - you can do 1.2 kg or a little more.

Moisture-resistant putty is applied in almost the same way as GF, so the flow rate is the same. Knauf Fugen Hydro can have different colors: rarely - white, more often - gray and even with pink shades. This is due to natural additives in gypsum, which do not affect the technical parameters of the putty and do not acquire a pronounced color after application and drying.

The price of Knauf Fugen and GF ranges from 400 rubles to a 25-pound bag.Hydro, in comparison with them, will be of great value due to its waterproofing and moisture-proof properties. The cost of such putty is almost twice as high - up to 1200 rubles. for 25 kilograms of dry mix.

Scope of application

Knauf Fugen standard plaster putty mix is intended for internal work of the following nature:

- GLC joints treatment (Knauf-sheets) with any edges, using paper reinforced tape;

- as glue for fixing Knauf sheets on a flat surface, as well as for gluing and processing plaster parts;

- disguise screw caps on the coating;

- filling compounds of concrete structures;

- alignment and correction of possible defects in wall sheets;

- as a starting coveron which you can glue wallpaper.

With a mixture of Knauf Fugen GF is very convenient to putty GVL and GKL. In this case, HS is also used to process walls of plasterboard with visible mechanical damage. It very easily masks all the flaws of the surface. Before plastering plasterboard taken primed. This process helps shape the wall.

Putty Knauf Fugen Hydro is known for its use in the treatment of wet rooms. This mixture is the most plastic among its “brethren” from the Fugen line. It can also give drywall the necessary arched, semicircular shape.without fear of cracking after drying.

The use of Knauf Fugen drywall putty is advantageous. After all, it not only helps to align the joints and can be a starting layer for further decorating the walls.

The solution of this putty is very convenient for the installation of gypsum panels. In the process of mounting Fugen is applied in the recess (groove) of the lower row of plates and in the vertical groove from the end. Gypsum sheet tightly pressed, the protruding residues putty removed. Then there is a process similar to the laying of bricks with cement mortar.

Any ready-made Fugen mixture dries equally quickly as applied to the surface, and quietly lying in the tank, where it was diluted. It takes no more than 30 minutes to dry, so it is very important to do everything right from the first layer.

Recommendations for application

Before applying the putty on the walls, it is necessary to acquire all the necessary tools for this process, as indicated in the official instructions for the mixtures:

- capacity for cooking putty;

- metal spatula for mixing;

- plaster mixer;

- metal spatula standard (15 cm);

- wide metal spatula (over 20 cm);

- metal spatula for processing corners;

- Abrasive mesh for grinding dry surface after puttying.

Experts recommend: before you apply paint or stick wallpaper, you have to walk on the putty surface with finishing mixtures.

Wash the container and all tools thoroughly. and release from residual traces of previous mixtures or use new ones. In a dirty container, fresh putty dries twice as fast, its service life is reduced to 15 minutes.

If there are unpleasant irregularities on the wall, they should be wiped after drying with a special grater. All tools must be made of stainless steel.

To mix the solution of the right consistency, you should pay attention to the following points:

- Pour the dry putty (1 kg) into water (0.8 l) slowly, spreading it throughout the volume. Handicraft is especially important here.

- As soon as the level of dry putty slightly exceeded the level of water in the tank, let the mixture stand. To this you can take no more than 2-3 minutes.

- Start active mixing. In rare cases, you can use the construction mixer, but the professionals insist on hand-kneading the mixture.

At first it may seem that the consistency is too thin to be applied to the walls. However, after a couple of minutes, the density will increase markedly, and the solution will become as it should.

Another tip: never drop the remaining grams of finished putty from the spatula into a common container. This reduces the service life of the solution and leads to an accelerated drying of still unused putty.

It should be noted that for the initial application a thinner consistency of puttyto make it easier to apply a thin even layer of up to 3 mm. For further use and for embedding irregularities, cracks and other flaws, the mixture will be more dense in structure. Then the thickness of the layer will not be so important.

You will learn more about the features of applying Knauf Fugen putty from the following video.