Sheetrock finishing putty: properties and application in construction

Sheetrock putty mixes under production conditions are ready for use. The use of such mixtures saves time, eliminates shortcomings, minimizes the risk of waste. You do not need water for mixing. You can simply open the bucket and begin the spackling process. This article will tell you about the characteristics and use of putty for finishing Sheetrock in construction.

Special features

For fast and high-quality work with plasterboard, it is recommended to use only first-class materials for finishing, to use auxiliary tools of proven companies and additional accessories. Combining all these factors improves performance and improves the final result. One of these products is Sheetrock putty.

The advantages of such solutions are obvious:

- improved performance;

- increased operational life;

- homogeneity and uniformity controlled in each batch;

- prolonged period of use (compared to self-prepared putties).

The product is available in packs of 28 and 17l. You can not doubt the quality of the composition, as it passes 10 phases of freezing / thawing during experimental tests and does not lose its properties at all.

If the Sheetrock product is in the cold, try to make the thawing procedure gradual. Do not use hot water and heaters for heating. Let the compound stand at room temperature. Then mix the product until a homogeneous mass, simultaneously getting rid of air bubbles.

Preparation for work

Stir the contents of the container, you do not need to add water. Apply the solution to the protective corners, heads of fasteners. For sealing joints with a construction tape, a small amount of water is allowed (it varies from 50 to 60 ml).

At the same time it is necessary to ensure that the solution was not too liquid.

Terms of Use

There are several basic rules for using Sheetrock superfinishing putty.

- The tool is intended only for interior work.

- New putting putty is carried out only on completely dried previous layer.

- The putty is sanded with emery paper with the 240th fraction.

- For successful dyeing and overlaying decorative trim, you must strictly follow the manufacturer’s instructions. In order for the paint to lay down well, the coating must be dry, dust-free, dull, should not stick to hands.

- Applying a thin leveling layer of putty to a drywall sheet helps to smooth the water absorption of the material. In the future, this will help avoid stains on the treated surface.

- In the process of dry grinding should not be too zealous. Do not handle the top of drywall and putty tape. Together with Sheetrock putty, paper tapes, tapes with a metallized liner and protective corners are used.

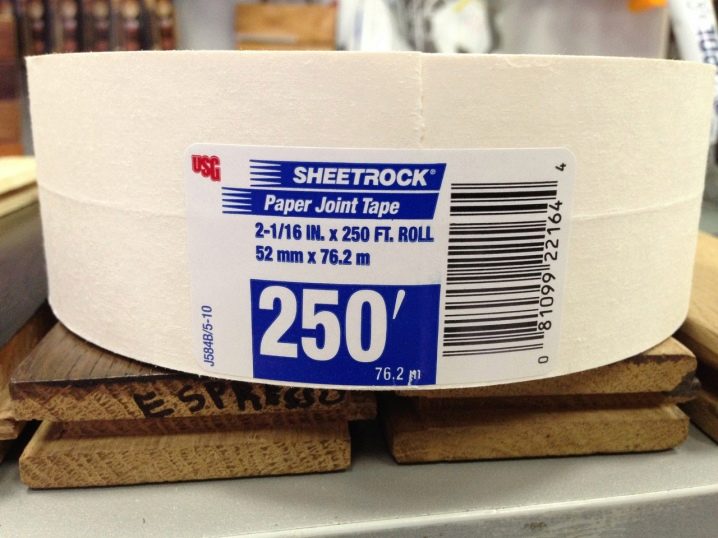

Features of paper tape:

- makes the design homogeneous, strong;

- has a fold in the middle for easy operation;

- does not need to use adhesive materials;

- has good durability;

Purpose of the paper metallized tape:

- reinforcement angles;

- reinforcement of structures when mounting drywall.

Features of metal corner protection on a paper basis (steel tires, protected from corrosion, on a paper basis):

- gives corners strength;

- does not need additional fasteners;

- the adhesion of the finished composition to the paper base is higher, which ensures perfect smoothness of the surface.

Drywall Seam Treatment

It is necessary to drown the fastener caps (screws, screws) into the surface of the drywall so that they do not protrude. To do this you need a screwdriver or screwdriver. Then with a stainless trowel you need to apply a continuous layer of Sheetrock putty, filling the joint between the sheets of drywall. Dip paper tape slightly into the putty layer. Tilting the spatula, swipe them around the tape. Press the tool firmly to release the excess solution.

Under the building tape should remain putty layer of about 1 mm. Then another layer of the mixture should be applied in order to prepare the base for the next finishing stage and protect the tape from edge twisting. Wait until the seam is completely dry.

After the entire surface gets rid of moisture, you can proceed to the next stage of puttying. Take a wide trowel (about 20 centimeters) and begin the second application step.

When everything is dry, “walk” with a spatula again to form the finishing layer. This time you should use a tool measuring 25 centimeters.

Corner treatment

For processing elements of the mixture is applied on both sides of the corner. Sheetrock tape folds in half and is applied to the mortar. Apply a thin layer of putty to one side of the corner, wait until it is completely dry and apply the same layer to the other side. Cover the tape with one, then the second side of the corner, removing the excess with a spatula.

Processing mounting screws or screws

Apply the finished undiluted mixture on drywall before sizing with paper tape and after. Fill the prepared mortar with the grooves that were formed in the places where the screws were fastened. Run the putty tool in the places where the screws are screwed in with pressure to even the layer of putty and the drywall sheet. This process should be repeated several times until the notches are flush with the surface to be treated. It may be necessary to apply several layers.

Drawing on paper corners

Construction professionals are strongly advised not to mix ready putties with water.The consistency must be the same as the manufacturer intended, otherwise the process will be disrupted.

Handle the edges of the corner with a Sheetrock putty with a medium spatula (about 12 centimeters). Wait for drying. The next application should be about 5 cm wider. And only at the end of the work, in order for the finishing layer to be smooth, you can add a little liquid to the putty.

The use of protective corners made of metal on a paper base

Paper-based corners have the same function as regular metal tires or PVC corners. But they are used when the connecting tapes are glued, and not when the installation of drywall is going to the base. Their plus is that the paper base in any case has better adhesive characteristics than the usual metal. Such a corner creates a more robust and uniform design, increases resistance to cracking, which may occur due to the natural shrinkage of residential buildings and industrial premises.

The difference between these corners and ordinary metal and vinyl corners is that the corners of Sheetrock are glued with putty, while ordinary corners are simply put on.Corners with a paper base ensure that subsequent layers of putty, decorative plaster and other materials will have a good layer-by-layer adhesion. The corner is pressed into the putty layer, after drying it is puttied.

Finishing stage of finishing

After applying the finishing layer, you must wait until all applied putty layers have dried. Then you need to smooth out the "bumps" with a spatula so that the surface becomes even. The rest of the solution is applied to the seams and fasteners. At this stage a slight addition of water to the mixture is allowed. The applied layers must be well aligned. This will reduce the processing time of the surface of the grinding float. It is also worth "walking" putty for all visible defects.

Ready putty mixtures are an ideal way to prepare plasterboard bases for further painting.. When applying glossy paints, all the irregularities and depressions can be seen on the wall. Using Sheetrock finishing putty eliminates the possibility of such situations.

Recommendations

In the process of grinding the seams is important to be careful. It is not recommended to grab the surface of a sheet of drywall, you only need to grind the seams.A grater strips the surface of the gypsum board, and paper fibers can spoil the finish coat.

It is recommended to apply the final coating on the entire surface to be treated in order to minimize the appearance of defects.

Reviews

Users confirm that Sheetrock’s pre-blended mixes are universal assistants in finishing work. Reviews about the quality and usability of mixtures are mostly positive. In this case, the main condition for a successful purchase is considered by many to be the correct determination of the consumption of material per 1 m2.

More information about finishing putty "Sheetrock" you will learn from the following video.