Vapor barrier during cold attic

Vapor barrier is a practical solution to the problem of the appearance of ceiling condensate in houses with a cold attic. The material prevents the penetration of moisture, protects the overlap from the formation of condensate and further destruction, and also prevents the occurrence of mold and fungus in the insulation plates.

Features of the device design

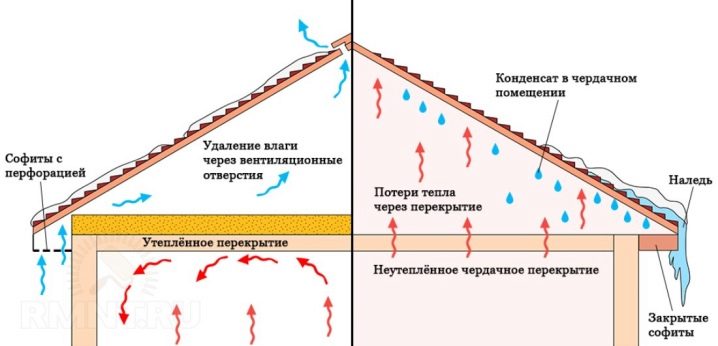

The cold attic includes the surface of a gable roof with roofing material and a warmed floor separating the living room from the attic. To ensure ventilation, the attic is equipped with dormer windows, without which the air exchange in the attic will be disturbed, which will lead to the formation of condensate on the roof.

The floor of the attic is a ceiling that serves as the ceiling of the dwelling at the same time. With a decrease in street temperatures, the overlap becomes subject to the appearance of condensate, the formation of which is caused by the temperature difference between its lower and upper parts.In order for the condensate droplets that do not appear to penetrate the ceiling, it is covered on top with special materials that do not allow water to pass through.

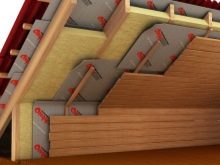

In addition to protecting the base from moisture, the material performs an important heat-insulating function, preventing warm, moist air from rising up. This technology significantly reduces the heat loss of the dwelling and allows significant savings on heating. Vapor barrier should be performed on any type of substrate, including concrete and wood floors. In the role of insulation can be used plates of isover, glass wool or bulk materials.

Types of materials

Before the advent of modern polymers, high fat clay was used to vapor barrier the ceiling in a cold attic. Its minus was quite a lot of weight and labor costs during installation. To date, the construction market offers a large selection of vaporizers, differing in the form of release, method of installation, properties and cost.

Foil Paroizolyanta

Parokizolyanty film - the most popular and sought after type which is represented by polyethylene and polypropylene films and a membrane:

- The most widespread polyethylene. This inexpensive and practical material reliably prevents steam penetration, but has limitations in use. It is recommended to use this type of film only in a warm climate under the condition of moderate temperatures: under the influence of extreme influences, it quickly loses its operational properties and collapses. The disadvantages include the low strength of polyethylene, which can lead to material ruptures at the laying stage. Pergamin often used as a vapor barrier is very similar in its properties to polyethylene: it also retains moisture well, but does not let the air through at all.

- A more practical type of vapor barrier is polypropylene.. Such a film tolerates thermal jumps and is highly resistant to UV light. The service life of this material is several times higher than that of polyethylene. Modern technologies allow the production of a film with the addition of viscose and cellulose. This greatly increases the strength and hygroscopicity of the material. Prerequisite for the use of such a vapor barrier should be the presence of good ventilation.

The water accumulated and retained by the pores of the material must evaporate freely, otherwise the properties of the material will be disturbed, leading to a dampening of the floor.

- The most modern and practical type of vapor barrier material are membranes. The isolant is designed in such a way that the ability to pass steam is possible only in one direction. Thanks to this property, there is a rapid removal of moisture, as well as air exchange between the ceiling and the attic room. In the domestic construction market, the Izospan model is considered the most well-known; its fleecy structure is capable of holding condensate droplets and evaporating them quickly. The installation of a membrane coating involves the mandatory formation of a ventilation space designed to ensure that the liquid has room to evaporate.

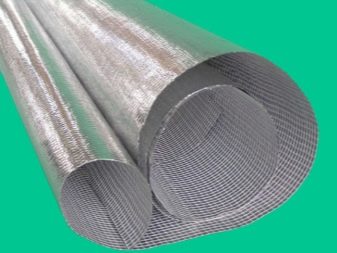

Foil materials

This look is intended for operation in the conditions of high temperatures and is used at construction of baths as vapor barrier of wooden beams of overlapping. Isolant is a film covered on one side with a thin layer of foil.Due to this structure, the material is able to reflect thermal radiation and retain steam well. There are several types of it:

- The most budget option is foil kraft paper. The material fits well, but in the process of long-term operation is prone to the appearance of mold and fungus. The disadvantages include its low hygroscopic properties.

- Kraft paper with polyester coating able to withstand temperatures up to 140 degrees. This allows you to use it as a vapor barrier material in the construction of baths. The disadvantages include low resistance to chemical compositions of detergents.

- Foil fiberglass It is considered the highest quality vapor barrier, and is characterized by high strength and long service life. The downside is the high cost of the material.

Liquid products

Liquid products to ensure the ceiling vapor barrier are represented by varnishes and mastics. The compositions are applied to the surface of the overlap and, after complete drying, form a thin film capable of retaining moisture and passing air. This contributes to good ventilation of floors and significantly reduces the likelihood of mold and mildew.

Some liquid products are intended only for use in non-residential premises and may be harmful to health if in contact with them. Therefore, when using them, personal protective measures should be observed.

Tips

Compliance with the simple rules of laying and operation standards will help to significantly extend the life of the vapor barrier.

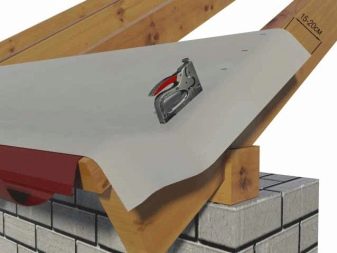

- It is necessary to fix the film material with the help of staples or small studs, placing a thin wooden lath under the fasteners. This will allow a better pressing of the material to the base and will reduce the likelihood of accidental damage to the film.

- The size of the overlap when installing any materials should not be less than 15 cm. Joints should be glued with a wide tape, and when installing materials from foil, you should use foil adhesive tape.

- Laying vapor barrier materials should be made only in the presence of thermal insulation.

- In the process of laying it is recommended to carefully control the tension of the material: the film should be in a free position. This will avoid breaking the material when it is stretched and compressed under the influence of thermal changes.

- For the formation of the insulation of the ceiling of a residential house, it will be sufficient to use a membrane or reinforced polypropylene film, and in the construction of baths, only foil-proofed vapor insulants should be used.

Vapor barrier is one of the prerequisites for the construction of houses and baths with a cold attic.

Properly selected material and proper installation will extend the service life of the floor, significantly reduce heat loss and make the stay in the room pleasant and comfortable.

For more information on ceiling vapor barrier, see below.