Vapor barrier: the subtleties of installation in a wooden house

The comfort of living is more influenced by the temperature and humidity in the rooms. In a wooden house, optimal conditions can be achieved with the help of heating and good thermal insulation. To reduce the negative effects of moisture on the walls, floor and roof, it is necessary to carefully monitor the level of vapor barrier, which is not so simple.

Special features

The high level of humidity adversely affects the structures of wood of any structure. Steam, which is released when taking a bathroom, preparing any dishes, washing, "trying to get out" of the house. Since its pressure is slightly higher than atmospheric, steam presses against the ceiling, walls and floor. As a result, together with the temperature difference, condensate is formed. Slowly getting into the wood and seals, water destroys them, which leads to the destruction of the entire building.

With the above problems cope high-quality vapor barrier.

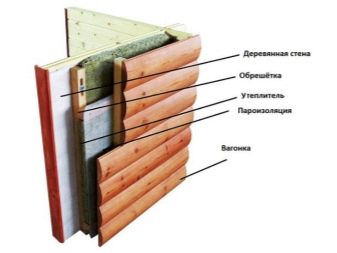

It can be installed in several layers, the joint thickness of which can be no more than 4 mm.

The joints of the sheets are insulated with self-adhesive tape or metallized adhesive tape. The vapor barrier is installed on the one hand, otherwise the walls will start to rot, and moisture will accumulate in the insulation.

When constructing a round wood structure can not provide space between the material and the film for ventilationas the tree has a rounded shape - the gaps will remain on their own. If the walls are erected of rectangular wood without bends, be sure to leave space for ventilation.

What is it for?

One of the characteristics of the tree is its property to “breathe”. In constructions that were built many years ago, it was not necessary to undertake any methods for the circulation of steam between the inner space and the street. In the current homes not only environmental friendliness, price and appearance are taken into account, but also compliance with all standards of energy saving. Because of this, wood is already a multi-layer construction of timber, insulation, waterproofing materials and the final finish.

A large number of layers does not allow steam circulation.As a result, steam is collected in a heater, it violates its integrity and significantly reduces the insulating properties, and the condensate slowly but surely destroys wood and promotes the development of mold and fungus. The tightness of the joints is broken, cracks are formed on the material. All this led to the decision to add another layer to the “cake” of the wall or concrete floor - vapor barrier, which would prevent the destruction of the wooden structure.

But even in a newly built wooden house there is a need to provide for vapor barrier. Materials such as carriage, sawn timber, semi-sheets are characterized by a high level of humidity and can dry for many years, which prevents the beginning of finishing work inside the room. In this case vapor barrier layer will reduce construction time.

Mineral wool is often used as insulation in apartments and houses. When it absorbs moisture, it begins to settle, loses its shape, and its protective properties deteriorate.

That is why the use of a layer of vapor barrier is an integral step in the device floor. Unlike wool, foam is installed so that its joints are sealed and not soaked with moisture.

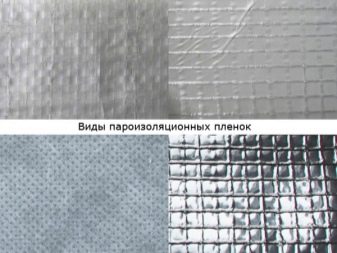

Materials

The construction market offers a wide range of materials designed for water and vapor insulation, which differ in both advantages and disadvantages. Breathing membranes and films are used to protect the walls in a wooden house, but there are other options for hydro and vapor insulation:

- Ruberoid - The indisputable advantage of this material is reasonable price. But roofing material is often used for laying on the roofs of outbuildings, but not for the walls of houses made of wood. In addition, this material is best used as an additional layer.

- Aluminium foil - on the one hand it is covered with metal, and on the other - it is equipped with a reinforced mesh. Such a device allows you to form inside the house a barrier to steam and a layer that reflects heat. To insulate the house, this material is placed metallized side out. Thanks to the foil, the house will not only be protected from the formation of corrosion, but also reliably insulated. Such material can be laid in the bathroom.

Installation of aluminum foil should be carried out with the utmost care not to damage it.

- Diffusion membrane. Vapor-hydro insulation protects the room from humidity, regulates its level, due to the property to pass air. The membrane has a special microstructure and has a high level of vapor permeability. The main advantage of the diffusion membrane is the absence of a ventilation gap between the thermal insulation and the membrane. Such hydro and vapor insulation well warms the room. But unlike other types, the membrane can be purchased relatively inexpensively. The most commonly used materials are the trademark "Izospan".

- Polyethylene or polypropylene film. Unlike polyethylene, polypropylene has a high level of strength and resistance to atmospheric influences. But on the side of the insulation condensate forms on the film, because of which the material quickly loses its properties. Over time, these deficiencies were eliminated, and today the film has a layer of viscose with cellulose at the base. It absorbs a lot of moisture and dries quickly due to air ventilation. The advantage of this material is reasonable price, durability and ease of installation. Also, the films will last a long time and will not lose their properties.

- Izolon - rolled insulation having a large selection of densities and thicknesses. The technology of insulation of these materials is effective, since the isolon gives off 98% of the heat, and in itself retains only 3%.

- Pergamin - budget option, which is a dense and thin cardboard, saturated with bitumen. This material is resistant to humidity and low temperatures. But keep in mind that it has a high flammability and short life.

Choose a quality material for vapor barrier is not difficult, the company Tehnonikol deserves good reviewswhich offers different types of steam and waterproofing. In the catalog of the company you can find a product that will meet your requirements.

Floor preparation

In order for all the planned work on the stove or wood to be done as efficiently and safely as possible, the floor must be carefully prepared. For this you need:

- The wood is treated with an agent that will protect the material from the formation of mold and mildew, as well as from the multiplication of insects.

- Perform the installation of the log and make the base - rough unedged boards.

- Lay the selected material (foil, wadding, adhesive film) to protect the structure.

To make a high-quality vapor barrier, it is necessary to repair the existing screed.

If the insulation is planned on the ground floor for a major overhaul, initially it is necessary to remove the floor covering, the finished floor, and then the rough boards. The insulating layer is also removed.

After the work is done, it is necessary to assess the state of the log and the supports of the floor structure. If you find the boards in poor condition, you will have to replace them with new ones. After completion of the repair work, you can proceed with the installation of a layer of steam and moisture insulation.

Assembly process

Laying a layer of vapor barrier in a private wooden house - the process is quite simple. Installation of protective material can be done by hand, the main thing is to follow the correct procedure and take into account all the nuances. Laying the vapor barrier is performed on the subfloor with one layer. All joints that are formed in the process, it is necessary to glue the special construction tape, this will ensure a high level of reliability and, consequently, quality. It is possible to stack material with an overlap.

To make the mount even more reliable, besides the tape, experts recommend using nails or a stapler with medium clips. Properly laid a vapor barrier means to follow this procedure:

- Be sure to prepare the subfloor - for this, process all the material with an antiseptic;

- perform the vapor barrier layer laying - lay the roll onto the frame, separate sheets are mounted with an overlap;

- fasten the material around the perimeter, carefully close all the joints and gaps;

- then go to the installation of insulation;

- after the bedding is insulated, it is better to install another layer of vapor barrier;

- at the end of the flooring lay flat.

Please note that according to the vapor barrier installation scheme, boards of a fair floor can be put only after all gaps, joints and emptiness will be eliminated. Basic flooring, such as linoleum, is lined up at the final stage.

If foil is used for the vapor barrier, its installation should be done with the metallized side up. Vapor barrier should be installed throughout the house, including in the shower. If necessary, experts recommend to perform vapor barrier walls.

That will be if to make mistakes when laying vapor barrier of a floor, look in the following video.

Professional Tips

Laying hydro and vapor insulation will take you some time.If you have never faced repair work and do not want to spend time on it, it is better to contact specialists immediately. And if you have at least some free time, then you will be able to install the vapor barrier on your own. Professionals recommend:

- Before installing a film, membrane, or other vapor barrier material, carefully read the manufacturer's advice. It is very important to comply with all installation conditions, the membrane must necessarily be laid with the right side in relation to the insulation.

- When installing the vapor barrier on wooden logs, note that the membrane sags to the ground by 2 cm to absorb and retain moisture in the film. To make the floor “cake” well ventilated, do not forget to leave a gap.

- Between the insulation, install two layers of vapor barrier, so you will achieve the best effect.

- What material for vapor barrier to use - an individual solution, carefully examine all the pros and cons of each type to choose the best.

Starting the device of floors in a wooden house, carefully select the material that will protect the structure from increased humidity, as well as increase the period of operation of insulation and floor covering.

If you have a limited budget, then you should pay attention to asphalt. But best of all proved multilayer polymeric membranes, which can be installed both in the living room and on the balcony. Membranes are resistant to adverse environmental influences and reliably protect against moisture.

About what vapor barrier materials, see the following video.