Features of waterproofing the floor under the screed

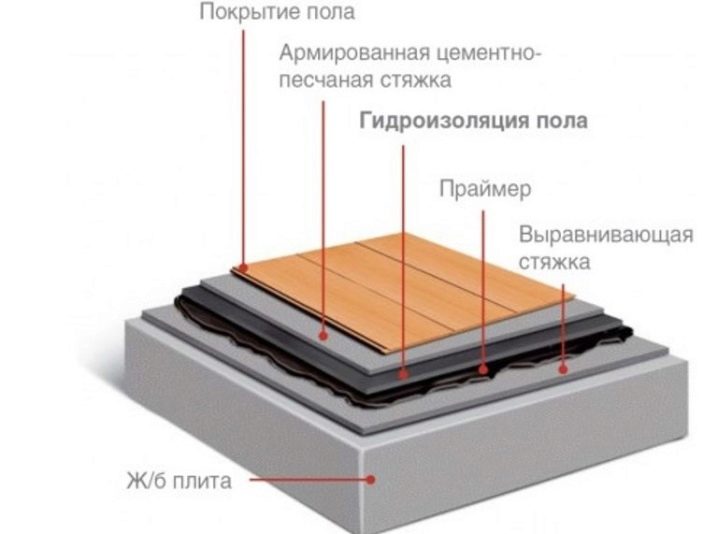

In the process of repairing the floor is one of the key steps. Compliance with the correct technology will allow the coating to serve for a long time and not lose its decorative qualities. Among the conditions for the installation of high-quality flooring is the arrangement of waterproofing under the screed. Its correct implementation is the most important task that will save the owner from many problems in the future.

Features and device

Waterproofing is a concept that occurs when any mention of repair work in new buildings or the overhaul. This is the process of laying insulating materials in various ways on the base before arranging the floor screed. Many are wondering how necessary this is and in what cases you can skip this step.

The main functions of waterproofing:

- Protection of the screed layer against wet impact.This is especially important if the apartment is located on the ground floor above the basement. Concrete coatings may lose their basic functions due to high humidity, reduce their properties, become cracked and crumble.

- The insulating layer prevents the ingress of moisture from the equipped room to the next. The possibility of flooding is high in the bathroom or bathroom. If water in large quantities falls on the floor, then without waterproofing, in any case, you will flood your neighbors on the floor below. Cement base is porous, it may have defects. Water will leak through them, as well as through the joints between the plates and loosely sealed holes for the pipeline.

In other rooms (bedrooms, halls, offices) the risk of flooding is significantly reduced. Nevertheless, there are heating pipes in them, during the laying of which gaps are formed. They are also better treated with waterproofing compounds.

- Maintain a healthy and safe indoor environment. Blocking the ingress of moisture from the outside excludes the development in the space under the screed of fungus and mold, which develop well in a warm wet environment. This is especially true for dry screeds.Between granules of expanded clay more space for the development of harmful microorganisms.

- An additional coating pre-levels the surface and facilitates the laying of the screed. It lays down more uniform and even layer.

- An additional barrier to external influences in rooms that are located directly above the ground. This primarily concerns private houses. Evaporation from the soil will lead to a violation of the integrity of the floor covering and the need to replace it.

Types and options

There are many ways to make waterproofing. The choice of the most suitable of them depends on your budget, and on the availability of necessary materials for sale, and on what room you are going to carry out repairs.

The following types of insulating coatings are usually distinguished:

- Obmazochnaya (plaster) waterproofing. It is produced using dry powder mixtures based on cement. They are sold in bags, diluted with water according to the instructions on the package. Such a coating is applied by analogy with plaster. The mixture gives the layer greater strength, stability and long service life.

- Painting. Liquid mixtures, mainly polymer mastics, sold in special plastic containers, are applied with a brush or a special roller.

- Paste insulation. It is produced using rolled materials in two ways. In the first case, the layers of coatings are glued to the substrate with the help of various compositions, not forgetting to glue the joints of the material and the place of contact with the walls. In the second case, the layer is glued in a heated state, the seams are also processed to avoid leaks.

Due to its non-environmental friendliness, this technique is undesirable for use in an apartment. It is better to use it in business premises.

- Compound. This type of waterproofing is mounted from different parts of the material with the treatment of seams. Relatively new technique gives guaranteed protection against leakage.

- Impregnation insulation. Perform its various liquid solutions with the addition of polymers. Efficiency is only in the case of work with porous bases, which are easily absorbing moisture: a coating of low-quality concrete and if you want to equip the screed on a wooden floor.

- Penetrating waterproofing. Basically, this type is used to repair the waterproofing layer. A mixture of binding or hydrophobic components is introduced into the defective places, cracks and seams.

Abrasive waterproofing is the most common, affordable and fairly reliable. It along with the painting and roll method can be used both in the apartment and in a private house. It is recommended to apply plaster insulation under a dry screed.

It is possible to apply mastic or rolled coatings both under semi-dry and under liquid screed. It is necessary to check that all seams on the insulation layer, if any, are reliably processed and glued.

If you are doing repairs in a new building, you should opt for the use of bitumen mastics. They are easy to use and at the expense of their elastic structure will not crack when the building shrinks.

If in your bathroom ceilings do not allow for the height of the application of a thick layer of insulating materials, you can apply an impregnating compound. It will protect even in case of abundant flow of water.

Materials

If only recently, almost all types of waterproofing works were carried out using roofing felt or bitumen, now you can choose more environmentally friendly, affordable and efficient products.

Below are several groups of materials for waterproofing:

- Liquid materials. The most famous of this group are mastics. Their main varieties: bitumen, bitumen-polymer and polymer. The first type is the most common and cheapest. It is only necessary to strictly observe the technology of work, since when heated, harmful substances are released. In order to improve the properties of bitumen, various components are added to it, such as latex or acrylic. Modified mixtures paint the surface with a dense layer.

- Primer - material based on bitumen and various polymers. But its main function is to prepare the foundation for applying waterproofing. Unlike mastics, it is perfectly absorbed into the surface, strengthening it and lowering moisture absorption. After applying it should be applied mastic.

- Liquid rubber - polymer composition for waterproofing. The material received its name due to its similarity with a dense and viscous material, although it is made on the basis of bitumen. It is very convenient to cover them with the base of irregular shapes. He easily evenly fills the surface and quickly hardens.

- Impregnation insulation - liquids with the addition of various polymers (polyurethane, solvent and others), used as a kind of primer for various porous bases: mineral or consisting of wood.They are popular in the application for insulation of flooring in parking lots, garages, warehouses and other industrial premises.

- Film waterproofing. Films are quite widely used before laying the screed. The layer is quite thin, but the installation method requires accuracy and time. They are made of polyolefin, PVC or polyethylene. At the same time, the material should be of sufficient thickness and density to perform its functions well.

- Membrane materials. One of the latest developments in the construction industry is made of PVC, polyethylene, or with the addition of rubber. Often for strength products reinforced. Fire retardants are added to the composition to increase the fire resistance. In general, membrane insulation is characterized by high resistance to aggressive media and low temperatures. Membranes "Technonikol" and "Tayek Soft" are very popular in the market.

- Roll materials. This is one of the first types of waterproofing. Coatings are available in rolls and overlapped on the floor with the plant on the wall. They are made of cardboard, non-woven synthetic fibers and fiberglass.Often in the composition can be found various resins and bitumen. Roofing material, self-adhesive insulation “Technonicol”, “Hydrostekloizol” and asphalt are common and popular for different applications. Roofing material is still profitable and easy to isolate the foundations. Cheap and easy-to-lay material does not have great durability due to the content of the cardboard in its composition. Over time, it may appear cracks.

- Relatively recently appeared type of roll materials - self-adhesive. Glue on the inner side has already been applied, and on the outer side one edge is processed at a distance of about 5 cm. This greatly simplifies the laying of such a layer. Also, rolled products can have a special coating, due to which you can fasten them together by fusing.

- Dry mixes - common and familiar to use products. It consists of cement, sand, various additives to improve the properties of the coating, better adhesion, deep penetration, fast drying, etc. Rigid waterproofing mixtures are diluted with water and applied as a plaster in a thick layer on the whole insulated base.Can be used for waterproofing in bathrooms and bathrooms, coating pipes in apartments, in private houses and even in open areas. Will withstand even the impact of water in the pool. Drying usually takes more than a day.

In stores it is not difficult to choose a suitable composition. High-quality and well-known brands: "Ceresite", "Master", "Krayzer", "Bergauf", "Prospectors".

Sequence of work

When performing waterproofing in the room must meet several conditions:

- Air temperature is not lower than +5 C.

- Humidity not more than 70%.

- Regulatory parameters must be set a few days before work begins and sharp temperature drops and drafts must be avoided.

Outside, most are required plus temperature, no rain, strong wind, ice and snow on the surface, and direct exposure to the sun.

The first step in the device waterproofing layer is surface preparation. It is cleaned of dirt and dust with a brush or spatula. Grease stains and chemical residues are best removed using specially designed solutions to improve adhesion with the insulating layer.

Next, the surface must be leveled as much as possible: measure the curvature, remove slides and build-ups, crack and deepen with repair structures. First, the gap must be primed. After treatment, the coating must comply with the deviations accepted in the current regulations.

Further, the laying processes will be different for different types of waterproofing:

- Before applying the coating insulation with dry mixtures, the surface should be treated with a primer in 1-2 layers, then let it dry. After that, the mixture diluted according to the instructions on the package is applied and leveled with a spatula. Cover the base, usually in two layers. And the second impose, when the first is already grabbed, but not dosoh.

Be sure to coat the walls to a height of at least 15 cm from the floor. After all the manipulations, the surfaces are allowed to dry and the necessary type of screed is performed.

?

- In the case of painting materials scheme is similar to the previous one. Only instead of a primer, you can apply primers or spray insulating compounds. But this is only necessary for rooms with constant humidity or a high risk of flooding. Mastics are applied with a roller in two layers, overlaying the wall.

- Polymeric or bitumen composition seizes, fills all defects and forms a perfectly flat and smooth surface. Before pouring the concrete screed, make sure that the composition is fully polymerized.

- For laying roll insulation after cleaning the base must be applied markings. All coatings are applied with an overlap width of about 5 cm. Further, depending on the type of hydroprotection, the areas are fused onto each other, glued by heating with a building hairdryer, fastened or used self-adhesive cloths. After installation, you can immediately proceed to the device dry or wet screed.

- Some premises require testing of the quality of the insulation layer. To do this, the floor is poured a couple of centimeters of water and kept in this state for about an hour. After that, adjacent rooms are inspected for smudges. When equipping the pool is very important.

Professional Tips

A few recommendations will help avoid common mistakes and improve the quality of your work:

- It is believed that roll materials provide the most effective protection. But modern builders have a different opinion.Films, ruberoid and other canvases do not let the air through. Therefore, over time, air gaps form between the screed and the waterproofing. Accordingly, the quality of the screed may suffer or lead to the need for dismantling.

- It is better to use dry mixes or membrane layers. After that, you can equip the finishing screed and its waterproofing by other methods.

- In the case of roll insulation, all seams should be carefully glued or treated to avoid leaks. The more overlapping sheets, the better, but not less than 3 cm.

All types of waterproofing should cover the lower part of the walls adjacent to the floor. Otherwise, there is no sense in such a layer - water will seep through the seams between the wall and the base.

- Liquid formulations should be used immediately. They can not be stored in an open and diluted state.

- Lay the insulating layer completely or on the problem areas in all areas of the apartment. In a private house, it is necessary for protection from moisture from the outside.

- If you can not decide on the type of waterproofing, carefully study the base: the degree of damage, permissible loads, humidity and material.After that, you can make an informed choice.

Good examples

Rolled waterproofing in the apartment is quite simple to install. The bands have overlapping each other. All walls below are covered with a layer of insulating material. After installation, you can, without stopping, to start pouring screed.

The coating method can be used to isolate the bathroom. The solution is applied evenly and comes to the wall. It is important to process all communications to avoid leakage through the seams. Before laying the tile or finishing layer screed remains to wait for the layer to dry. As a rule, the setting time is at least one day.

The scheme of bitumen insulation of the floor involves the use of a primer. The leveling screed eliminates unacceptable curvature for the mastic. Primer solution will enhance its protective properties. After that, you can safely arrange a cement-sand layer of the required thickness for thermal insulation of the desired floor level.

It is also recommended to lay a waterproofing layer on dry fill with expanded clay. In this case, a thin film of polyethylene can be used.This will reduce the consumption of concrete solution, and improve the quality of the screed by retaining the right amount of water in its composition.

On how to waterproof the floor under the screed, see below.