Vapor barrier for wood ceiling: selection criteria

To keep a comfortable microclimate in a wooden house, you need to take care of high-quality vapor barrier of the ceiling. Similar elements are also needed to prevent excess heat loss. Good vapor barrier prolongs the life of the insulating layers, so you should not neglect its installation.

Special features

In a residential building, there will always be water vapor. It rises rapidly in the process of washing dishes, cleaning, cooking and other such matters. Even households themselves are a source of steam. Currently, in most homes there is high-quality ventilation, which removes it from the living space, but a considerable dose of vapor still remains. This often causes a lot of trouble.

Vapor barrier is necessary so that no detrimental moisture accumulates in the insulation layer. That is why before laying the warming layer the ceiling in a wooden house, you first need to reliably paroizolirovat. Otherwise, condensate will accumulate in the inner part of the insulation due to temperature jumps. This can lead to rapid deterioration of the insulating material. The presence of condensate in the insulation often leads to the appearance of fungus and mold, which is not so easy to get rid of.

Today on the market there are many materials that can play the role of a vapor barrier in a house with wooden ceilings. Most of them fit easily enough. With such a work will be able to cope with the usual home wizard, who does not possess special skills.

Without vapor barrier of the ceiling is not enough if we are talking about rooms with a high level of humidity. These areas should include a kitchen, bathroom, bathroom. In these spaces, special vapor barrier films are most often used. Without such additions, thermal insulation material on the ceiling can quickly become unusable.

Vapor barrier materials are also needed in steam rooms. Most often, coatings that additionally have heat-reflecting properties are used in such environments. Thanks to such materials, a comfortable microclimate and warmth are always maintained in the room.

According to experts, vapor barrier materials are especially needed if the wooden floor is located between heated and unheated rooms. For example, this may be the space at the base of the attic between the warm floor and the unheated area under the roofing materials. It should be borne in mind that the vapor barrier of a wooden house will be most effective if it is laid out in a single circuit.

It is necessary to mount a vapor barrier material under a heater with a small sag. This condition is mandatory, since these materials can narrow and expand under conditions of temperature extremes.

Purpose

In the process of building or repairing a house, special attention should be paid to the vapor barrier. It is necessary for the following purposes:

- vapor barrier "prolongs the life" of the ceiling, actively protecting the floor in the attic from the accumulation of moisture and destructive condensate;

- high-quality vapor-insulating materials are designed to extend the service life of roofing coatings, which are used for the arrangement of floors of wood;

- if there is no mold and fungus in the attic floor, it will last much longer and will not cause any problems;

- vapor barrier materials also contribute to the preservation of heat in residential areas, performing to some extent the function of a heat insulator;

- the layers protecting the floors from the accumulation of condensate make them more fireproof, which is very important for wood substrates;

- vapor barrier coatings protect the heat insulating material from excess moisture and condensate;

- vapor barrier in a single combination with thermal insulation ensures a comfortable microclimate from inside the room, as it reduces heat loss and is responsible for maintaining a stable level of humidity;

- In addition, the vapor barrier for wooden floors can also act as an additional hydro and wind insulation of the house.

Consider that the vapor barrier works more efficiently if there is a high-quality ventilation system in the room.

Materials

Different types of materials are used for the qualitative vapor barrier of wooden floors. Each of them has its own distinctive characteristics, pros and cons.

- Polyethylene film. In the ranking of the most popular and common materials for vapor barrier ceilings polyethylene film occupies a leading position. To make such a coating more reliable and durable, it is often additionally reinforced with mesh or textiles. A simple non-perforated film is a special impermeable barrier. It perfectly isolates excess moisture and moisture, and also protects the base from the accumulation of condensate on the roof and insulation. Also, modern manufacturers produce and perforated variety of polyethylene film. It contains microscopic holes that allow the condensate to evaporate even faster.

- Pergamin. This is another popular vapor barrier material. It is sold in rolls and is made of thick cardboard, which is pre-impregnated with bitumen. Glassine is an affordable material that is inexpensive and is found in many stores.However, it cannot boast of a long service life.

- Polypropylene film. One of the sides of such a film is covered with fibers of cellulose or viscose. Such processing is necessary for more effective absorption of moisture. The material retains the water droplets, after which they gradually evaporate. Polypropylene film is more durable and durable vapor barrier, especially when compared with the polyethylene version.

- Aluminium foil. Aluminum vapor can be used to vapor barrier wooden ceilings. This material has the function of a heat reflector. The basis of such raw materials can be paper or polyethylene foam. Such materials can boast excellent vapor barrier properties. In addition, aluminum foil fills the living space with heat and effectively retains it in conditions of heated space.

Such material is perfect for spaces with high levels of humidity. They can be safely installed on wooden floors in kitchens, bathrooms, baths and saunas.

- Diffuse membrane film. This material is micro-perforated.It combines non-woven polypropylene and polymer film. Diffuse membrane vapor barrier is single- and multi-layered, as well as single- and double-sided. Membrane-based insulators form a robust vapor barrier on the ceiling. They have a special diffuse film that does not trap moisture. She, falling on a similar surface, evaporates pretty quickly. Experts recommend using a double membrane. Such a vapor barrier will be more efficient and reliable.

- Lucky and mastic. Today, in stores you can find special varnishes and mastics, which have a membrane effect. They do not let the moisture through the outside and do not interfere with the "exit" of steam from the living space.

Instruments

For laying and fixing the vapor barrier you need to stock up on the following materials and tools:

- wooden planks with a width of 10 cm or steel profiles for the manufacture of crates;

- tongue-and-groove boards (these materials will be needed for arranging the floor in the attic);

- screwdriver;

- construction stapler and staples.

How to lay?

Installation of the vapor barrier is not too complicated and inaccessible.The standard way to install a vapor barrier involves its installation from the inside of the ceiling.

But it should be borne in mind that in regions with a harsh climate, vapor barrier must be installed on both sides - inside and outside.

For a start, the base must be prepared before installing a vapor barrier on it. It should be cleaned from dust and dirt. All cracks (if present) cover up with special means. Cover the ceiling with a primer and dry thoroughly. Installation of film vapor barrier must be made before laying the insulation material. It is necessary to try to install the vapor barrier in such a way as to avoid its sagging in the future. Laying the edges of adjacent films should occur overlap.

How to fix?

At the end of the installation of the vapor barrier material, it should be properly fixed. After the installation work is completed, all joints and seams should be glued with tape. To securely fix the vapor barrier material, it can be nailed on special nails with wide caps. Instead of such fasteners, it is permissible to use a conventional construction stapler with brackets.

To avoid rupture of the film, an additional cardboard lining should be put under the staples. It is necessary to arrange gaps between brackets no more than 30 cm.

In the process of filing the film on the rough ceiling, it must be fixed with a batten. This design is most often assembled from metal and steel profiles. In order for the ceiling vapor barrier to be of high quality and correct, you need to carefully study the instructions that most companies attach to their products.

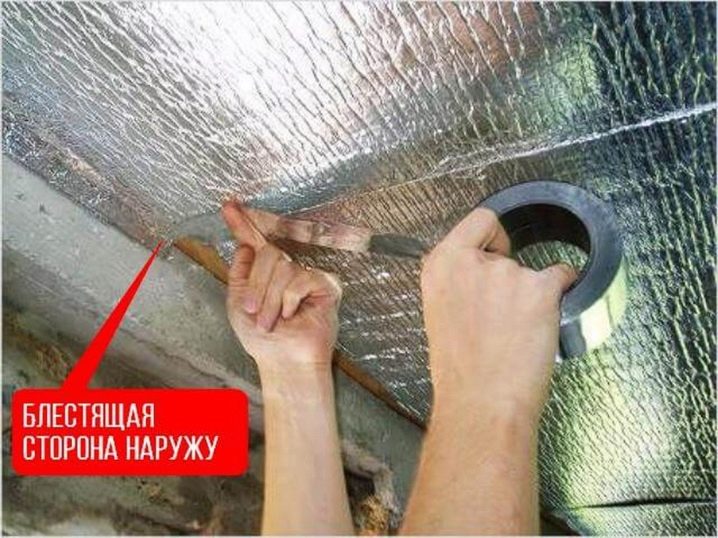

If you lay the cover on the wrong side, it can lead to the opposite effect of vapor barrier. In this situation, condensate will accumulate under the insulating layer, which will quickly lead to its destruction.

Manufacturers

The vapor barrier material for hardwood floors must be of high quality and reliable. Today, there are several of the most popular brands that produce products that meet all the listed qualities.

- MegaFlex. This large manufacturing company produces high-quality steam and waterproofing materials, as well as wind-proof films and membranes that are suitable for both concrete and wood floors.According to the statements of this manufacturer, its products are high-tech and are on the cutting edge of technological progress. The range of "Megaflex" is quite rich and diverse. Vapor-permeable materials of the company - “Megaflex” A, A2, A3, A4, A140, D110 are very popular because they perfectly erode condensate and retain heat in the room.

- Juta. This well-known Czech manufacturer offers the choice of consumers high-quality hydro, wind and vapor insulation. The Juta range includes vapor-proof roof-permeable roofing, as well as materials intended to form a barrier on the inner surface of the thermal insulation on flat and sloped roofs. This well-known company assists in the calculation of the necessary volumes of material, and also delivers and unloads raw materials by meter of work.

- Tyvek. This trademark belongs to the well-known American company DuPont, which today is among the 100 largest companies in the world. This popular and well-known manufacturer produces not only paroizoliruyuschie and waterproofing materials, but also special clothes, stationery, car covers and medical packaging.Tyvek vapor barrier membranes are very popular because they are able to maintain an ideal level of vapor barrier while maintaining vapor-permeable properties. Such products prevent the greenhouse effect, regulate the level of humidity in residential areas, and also extend the life of the building. In addition, Tyvek's vapor barrier materials are durable, easy to install and environmentally friendly.

- "Izospan". Vapor barrier materials from the company "Izospan" are widely used in the construction of private houses and large buildings. Of the considerable number of domestic firms of this manufacturer highlights the fact that he has not only fire and hygiene certificates, but also a certificate of GSSSTROY RF. Many consumers choose Izospan products, as they are characterized by unsurpassed quality, are durable and have an affordable price.

- "Nanoizol". This manufacturer specializes in the production of high-quality vapor barrier and membrane materials, which are produced using Russian and European equipment.Materials "Nanoizol" are made on the basis of carbon fibers, therefore, they have an unsurpassed sealing quality. In addition, the range of this manufacturer is represented by various lines, from which it will be possible to choose the right products for solving any construction tasks related to hydro and vapor insulation.

- "Duke". This major manufacturer produces hydro-windscreen, under-roof waterproofing and under-roof vapor insulation based on polymers. According to the representatives of the company "Duke", their vapor-permeable membrane materials simultaneously isolate the base from wind and moisture, as well as dust, dirt and soot. Insulating films of this manufacturer can be installed for any type of roof and facade. It is worth noting that the products of the company "Duke" can boast not only high quality but also a democratic price.

Tips

If you want to install a vapor barrier material on a wooden floor in a house of aerated concrete or wood, then should take into account some of the advice of professionals.

- Do not neglect the installation of a vapor barrier material, since without it the insulation will not last for a long time.

- You should not fix or nail insulation material, if you have not yet become familiar with its characteristics and properties. As a rule, all the necessary information is applied to branded packaging.

- Experts say that the perforated variants of thermal insulation are more effective, since there are many micro holes in them. Such materials are more expensive, but they are more effective.

- It is necessary to treat the insulating material with care. It should be remembered that the vapor barrier layers can not be pierced with nails. To protect the vapor barrier from damage, it is recommended to refer to the frame installation method.

- It is necessary to make clearances for additional ventilation. Between the insulating film and finishing materials it is necessary to leave a gap of 5–7 cm. This nuance is especially important when it comes to a cold space or a room with a high level of humidity.

- Pay attention to the tightness of the vapor barrier. To protect finishing materials from condensation, it is necessary to ensure maximum tightness of the vapor-permeable formation. And in order to remove excess moisture, the room must have a high-quality ventilation system.

- Insulating film should be laid without undue tension.It should lie free and sag a little. Otherwise, the material may rupture.

- Remember: the rough side must "look" inside the room, and the foil - out.

- The film must be laid overlap. In the process of this work, all joints should be fixed with strips of adhesive tape (no wider than 10 cm) or double-sided adhesive tape.

- If you decide to fix the insulation material with a stapler, then pieces of paper or cardboard should be laid under the brackets.

- It is recommended to fasten the whole material in the corners. This will allow to better cover such areas.

- To seal the vapor barrier was of better quality, it is recommended to put it, grabbing the wall.

- Experts say that the vapor barrier materials do not tolerate exposure to sunlight. Just one season is enough for the open area of such coverage to become unusable.

- For gluing film joints with foil-coated surfaces, it is correct to use exclusively special metallized adhesive tape.

- A small supply of vapor-permeable film should be left in front of the windows.

- Before you go shopping for a vapor barrier material, it is important to calculate the required amount. It should be borne in mind that the roll options are overlapping with allowances, so their size should be larger.

- It is necessary to lay vapor barrier materials horizontally (bottom-up). As for the overlap, it should not be more than 15 cm.

- After mounting the vapor barrier layer, lags are placed on top of it, on which it will be necessary to attach finishing materials. Most often used for this coating such as fiberboard, wall paneling or MDF.

If you are going to choose a suitable steam insulator yourself, then you should refer to the products of well-known and trusted companies. Materials from leading manufacturers, as a rule, are of good quality and are environmentally-friendly.

For information on how to properly isolate the ceiling in hardwood floors, see the following video.