Laminated doors: pros and cons

The times when laminate was used only for flooring are long gone. Today, this material can be seen on the walls, on the ceiling and even on door panels. Such non-standard solutions allow you to refresh the interior design and give it a special style. Today we will examine in detail all the pros and cons, as well as the features of the doors, finished with laminate.

Advantages and disadvantages

The advantages of the laminate include its performance:

- durability;

- wear resistance;

- heat and sound insulation qualities;

- Beautiful design;

- wide range of colors and textures.

The disadvantages of this material is not so much. Experts do not recommend installing it in places under direct sunlight. This may cause fading of the panels.

As for the entrance door, trimmed with this material, it can be supplemented with a canopy made of galvanized or metal sheeting.

Types and features

Distinctive features of such a popular and relevant material as laminate are:

- its ability to perfectly imitate even the most expensive and valuable woods;

- good sound and heat insulation properties, which the laminate achieves due to its porous structure, which is a useful property for the door trim;

- its installation on the door is quite simple and quick.

This unpretentious and very attractive finishing material can be issued:

- input;

- interior canvases.

It is possible to do the finishing of the doors with laminate with your own hands, but for this you need to know the basics of this work so as not to harm the foundations.

What is it made of?

The lion's share of modern brands produces a laminate consisting of four main layers:

- The top layer is a film that protects the panel from sunlight and scratches, bumps or dirt.This laminating film is made from special decorative paper and, as a rule, is impregnated with melamine-formaldehyde resin. It is applied to the wood panel by pressing. Often the film is treated with varnish, which makes the laminate more attractive.

- The next layer, which is under the film, consists of paper with a print impregnated with resin. It can repeat stone, solid, tile or brickwork.

- Then follows a layer of wood-shaving or wood-fiber base, which is made by pressing wood waste together with glue. Such constructions are elastic and dense. Some factories produce more environmentally friendly options in which this layer consists of pure wood, but these options are much more expensive.

- The lowest layer is a cardboard or plastic, impregnated with paraffins.

Materials

Most often the laminate is finished with metal doors. With the help of such additions, the canvas becomes more attractive, aesthetic and presentable. In addition, the laminate provides doors and additional sound and heat insulation, as it has a porous structure.These characteristics play a significant role in the design of the canvas.

Steel doors, laminated, look much more interesting and are more reliable. Modern consumers increasingly prefer such design solutions, since canvases made of natural wood are very expensive, and with a simple floor laminate you can give the iron door a similar appearance.

Laminate flooring is often finished with interior doors made of cheap laminated chipboard. As a rule, these canvases look quite simple and patterned, and with the help of laminate panels, their appearance can be radically changed.

Deaf panel structures are best suited for such purposes, as for models with glass inserts it is much more difficult to select a laminate.

Dimensions

Modern furniture manufacturers produce door designs completely different sizes. You can choose a suitable canvas for both compact and very spacious doorways. Meanwhile, the standard parameters of the doors are:

- height - 190-200 cm;

- width - 60, 70, 80 cm.

Some factories produce more impressive specimens, whose width is 550 cm, and height - 1900 mm. You can also order the door according to individual measurements.

Colors

Modern buyers most often prefer finishing doors with a laminate of natural shades. On its surface can be viewed prints and drawings, as in real wood. The most sturdy and attractive panels are:

- imitating bleached or bog oak;

- luxurious wenge;

- aristocratic mahogany;

- an attractive nut;

- soft brown alder;

- light pine

Of course, today in stores you can find laminate and other popular shades. For example, it can be airy milky, beige, cream or snow-white finishing material. Lovers of darker panels can pick up a laminate of black ash or dark gray color schemes.

Selection of the optimal and suitable shade of the material should occur on the basis of the basic color solution of the interior or the dwelling as a whole. It is necessary to create the most harmonious and beautiful ensemble.

Required tools

For lining the door with laminate, you must use different tools. So, for cutting panels most often use a jigsaw, a grinder or a miter saw. In addition to these devices will need:

- roulette;

- gon;

- pencil;

- mallet;

- perforator;

- screwdriver;

- level;

- scissors for metal;

- glue in tubes.

Class and Marking

There are several classes of laminate:

- 21, 22, 23 class - these are panels related to the household category, designed for minimum loads;

- 31-35 class - commercial laminate, designed for different loads, for example:

- Class 31 is designed for light loads. It is recommended to use only for the floor in the bedrooms.

- Class 32 withstands average loads. It is often used in office space.

- Class 33 are very durable panels that are quite suitable for finishing both interior and front doors.

- Class 34 is the most reliable and durable laminate that easily withstands very large loads.

- 41, 42, 43 class - production laminate, produced by special orders.

Decor

To give the doorway a more aesthetic appearance, you should finish the old slopes on the same principle as the canvas. For this, measurements of their dimensions are made and a base is prepared for them. The perfect finish of such parts are slats made of wood. To hide the seam between the panels of the laminate, you can make sawing at 45 degrees. Slopes should be arranged on both sides of the door.

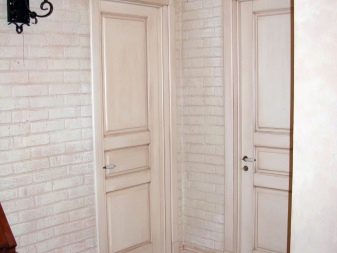

Style and design

The design of the door leaf with laminate should match the style and color in the main interior. First of all, you need to monitor the combination of the canvas and floor covering. For example, doors with a white coating will look with any colors of the furnishings, and for brown canvases it is better to select a floor of a similar shade differing in a couple of tones.

Such door designs, supplemented with laminate, will look organically in different styles, for example:

- Provence (suitable with gray, white and pastel laminate);

- classic (better to use expensive panels that mimic natural wood);

- country (suitable doors with laminate, having a rough wooden print);

- minimalism (in this style, you should use concise monochrome panels without unnecessary drawings).

How to choose?

When choosing a laminate for door finishing, you should rely on the following criteria:

- Material class For cloths, it is better to use high-class panels, especially when it comes to entrance doors. The most durable and sturdy designs are 34 classes.

- Colour. Pick up the shade material correctly. It should be combined with the surrounding decoration and furnishings, as well as fit into the stylistic decision of the interior.

- Manufacturer.Contact only well-known manufacturers, so as not to run into low-quality material.

- Price. Do not buy too cheap laminate, even if it has a high marking, as such options may be poor quality and fragile.

Preparatory work

Before installing the laminate door you need to prepare. Consider the installation steps on the example of a metal sheet. It must first be cleaned of rust (if any) and treated with anti-corrosion compounds.

The door must be removed from the hinges and put on a prepared base. It is necessary to remove the fittings and clean the base with a brush for metal or a nozzle on the drill. Then you need to degrease the door (suitable gasoline or solvent) and go through the primer (only after the degreasing is completely dry).

Installation and installation technology

To sheathe the door, it is better to put it in a horizontal position (for better fixing of the panels on the surface). Laminate must be cut into blanks for the entire width of the canvas. Covering is better to start from the inside of the door.

Each part should be applied with glue or liquid nails, and the remaining lines should be fixed with a lock joint after the previous part has been dried with a building hairdryer.After the entire side is glued, it needs to be allowed to dry (you can put a load on the surface for better fixation).

After that, you can glue the decor on the ends. Suitable veneer ribbons to match the finish. They can glue the canvas or fasten on liquid nails. Upon completion of the upholstery and decoration, you can return the accessories to the place and return the door to the hinges.

See how to insulate the front door and sheathe it with laminate, see below.

Successful examples and options

Laminate can be used not only to decorate the door, but also to finish the arch inside the room. This solution is suitable for both dark and light ensembles. The main thing is to correctly select the shade of the panels.

Cheap interior linen after plating laminate look much more attractive and richer. It is important to carry out all stages of work correctly and accurately.

An important role is played by the design of the entrance fabric from the inside in the apartment. The door must fit the design of the hallway or corridor in terms of color and texture, and in style.