How to make a door with your own hands?

The strength of character lies not in the ability to pierce walls, but in the ability to find doors. And even better, not only to be able to find them, but also to be able to create these doors. This article will discuss how to use your power in everyday life and how to make the door with your own hands.

How to prepare

It would seem that the modern market is so wide that you can find a door of any shape, size and quality on it. But this is not always the case. Especially when it comes to exclusive, special sort of wood, spectacular stained glass window, uncommon form. Buy standard factory design - boring and ordinary. And to make the door with your own hands is quite an easy task, especially if there is a suitable canvas, a pair of skillful hands and a little time.

However, in order to make a beautiful and high-quality door yourself, you must first study the subtleties and nuances of the material, assess the complexity of the technology and calculations, and identify the pitfalls during its installation.

First you need to prepare all the materials and tools that will be needed for work. After all, the final result is influenced not only by the quality of the raw material itself, but also by the quality and reliability of the auxiliary tools and materials used in the assembly and installation of the door. And for this you will need:

- the milling machine with the manual mechanism. With its help, they carry out the processing of wooden products, give it shape, grind groove elements;

- manual circular saw;

- Bulgarian. In this case, will serve to polish the wood;

- screwdriver for mounting the door;

- construction level and tape measure;

- hammer;

- pencil or marker.

Regardless of what type of product you need to make, whether it be interior, entrance doors or doors for a country house, the same technology is used for all. Therefore, having studied this article, you can easily make home-made doors for any needs.In addition to the tools, you also need the material itself. As a rule, choose an array of different wood species: oak, ash, birch, larch, pine.

Some prefer exotic breeds: mahogany, wenge, beech. The choice depends on personal preferences, the type of room and the overall concept of the interior.

When making a construction with your own hands, you need to take into account the fact that a wooden canvas will require pretreatment, especially for hard woods. When choosing a wooden canvas, you need to focus on the fact that the wood was flat, smooth. There should be no cracks and holes from the knots. To start, the chosen board is dried in a well-ventilated room at a temperature of about 25 ° C.

You can also dry on the street, but only in dry weather, preferably in the summer time of central Russia. Depending on the type of wood and its initial state, the drying of the leaf can take up to ten days.

Popular models

Before proceeding to the manufacture of the door, you need to think about what type they will be (mounted or sliding), to determine the shape and design. The most important characteristics of all doors are functionality and appearance, because they will become an integral element of the interior.

We characterize the main models:

- Today is very popular sliding doors. The door of the "coupe" can be either single or with two doors. Sliding doors on rollers - an alternative to the usual options with hinged doors, especially if the urgent need to save space. There are two types of sliding doors: with lower guides and with upper ones. So, using a mechanical system with lower guides, the door “walks” along the built-in rollers, reducing the load on the walls.

It is advantageous to use such a system for fastening a sliding door to thin partitions in apartments.

- Among compartment doors especially popular designs with a hinged mechanism. Hinged compartment doors are usually made of glass, because of its smaller mass compared to massive wooden counterparts. In addition to the fact that this type of door also takes up little space in the apartment, plus it also lies in the fact that its glass surface perfectly transmits light to the room. This option is very appropriate if you plan to overhaul the "Khrushchev" in order to release and so small area of the apartment from unnecessary structures.

- Door-book, like a compartment door, helps preserve usable space in an apartment. Its folding structure consists of two separate canvases interconnected so that when opening one part falls on the other with the same, without cluttering the interior. They are often put in dressing rooms and in bathrooms at a bedroom.

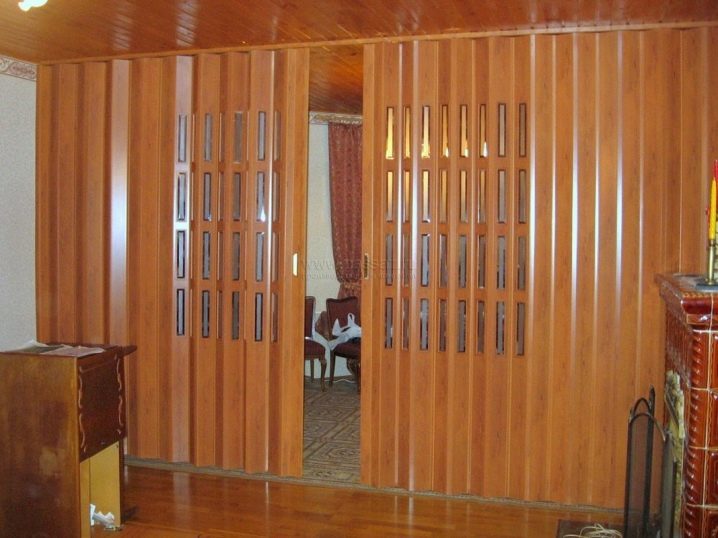

- Door accordion - Another option for small apartments. Compared with swing doors, these doors can save up to two meters of space. This type of product can be used in any interior. The design of accordion doors is varied. There are even interesting options with intricate stained glass windows.

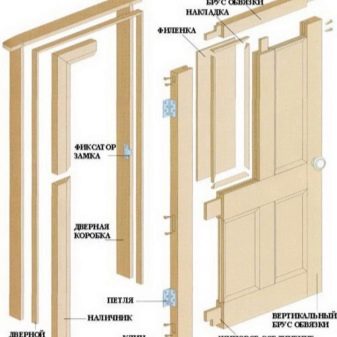

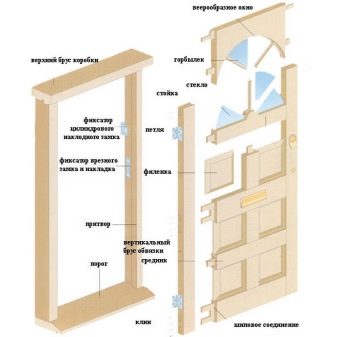

- Well known framed doors remain popular to this day because of their aesthetic characteristics. The paneled door differs in design from the usual one in that additional thinner canvases are inserted inside the door frame. Thereby, even the most boring door can be made very original, using inserts with textured patterns or carvings. The area of use of these doors is not only office premises, but also residential houses and apartments.

Manufacturing

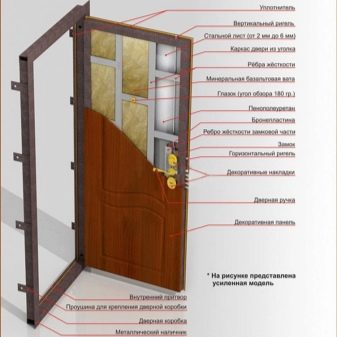

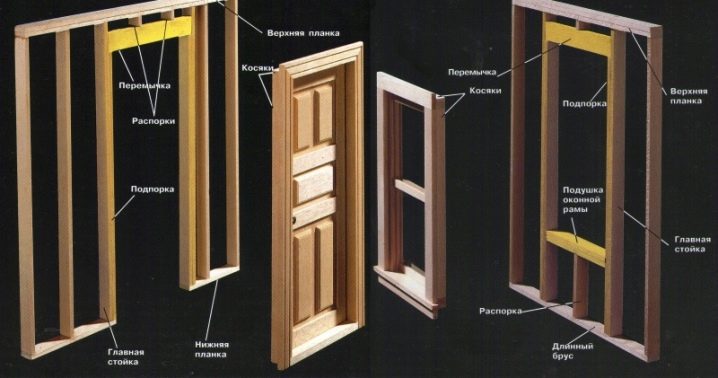

A standard hinged door consists of several parts:

- door frame;

- door leafs;

- fasteners;

- the castle;

- frames in the form of platbands.

If the fabric of the product is not a monolithic board from an array, but has several components, it is necessary to clarify what they will be made of and what their functional purpose is. Frame design is the frame. It sets the main dimensions of the product, gives it rigidity and shape. The outer visible part of the web is represented by the skin. In this quality can serve not only wood panels, but also plastic profiles or stained glass.

If the task is to make the front door, then you need to take care of the insulation that fits inside, under the casing.

This article will provide information on how to independently make the door of the simplest design with a hinged attachment mechanism, without insulation and complex plating options like glass decorative elements and carved panels.

Measurements

Seven times measure cut once. This proverb will be more appropriate than ever in the independent manufacture of a door. Indeed, the final result will depend on how correctly the measurements will be made. And to come up with what parts need to be measured, it is not necessary.All the basic parameters have long been known, it is enough just to write them out on a sheet of paper and measure it with the help of an ordinary building tape measure.

It is imperative to measure:

- door width (the distance from the left to the right edge of the canvas);

- door height (distance from the floor to the top point);

- doorway width;

- doorway thickness;

- opening slope (if there are distortions);

- evenness (to determine the elements whose size differs from the main one).

Determining the width of the product, it is recommended to measure the distance between the side portions of the opening in the floor area, in the center of the opening and at the upper border of the opening and find the average value. If necessary, if these values differ, the opening can be trimmed.

For an interior door, the width is usually 80-90 cm, for the entrance door - 90-120 cm. The door height is determined by the height of the opening and is approximately 200-210 cm. Measurements are made with the same tape measure from the floor to the upper point of the door opening.

It should be taken into account that if there is no floor covering in the apartment, then the measured height will not be entirely accurate, therefore for the beginning it is recommended to finish the work with the floorso that all parameters of the future door are taken into account correctly. When determining the height of the door, measurements are also carried out on three points (leftmost, center and rightmost).

The thickness of the doorway is measured like the width of the door. Only it is necessary to take into account that the width of the box will be somewhat larger, since it is necessary to leave the distance between the door and the box for the door's free running. And yet, when forming the box, it should be remembered that its width should be several centimeters less than the measured width of the opening, since during installation it is necessary to leave technological voids.

The thickness of the doorway is measured at six points (thickness at the bottom, middle, top for the left edge and the same positions for the right edge). This parameter will depend on the thickness of the wall into which the door will be mounted. For the entrance, it is usually more than for the interior, but there are exceptions. Here you should also pay attention to the presence of non-standard dimensions of the thickness of the opening. In this case, it is necessary to provide dobory that will compensate for this moment.

In order to simplify the installation design, you must first determine the evenness of the opening. With the help of the construction level, the vertical of the opening (three points) and the diagonal are checked. With a tape measure the distance inside the opening is diagonally measured, from the top to the bottom angle, for each side. Both values should be approximately equal. In case of strong deviations, not only the appearance of the structure will deteriorate, but the reliability of the mounting system is also questioned.

After the basic parameters have been measured, they proceed to the correction of irregularities and distortions. To do this, carry out the plastering of these places or cut off the excess with the help of the grinder. The alignment of the opening with the help of gypsum plasterboard can be an ideal option.

Elimination of deficiencies identified in the process of measuring the dimensions of the product will certainly have a positive impact on future work and eliminate many unpleasant moments during installation.

Materials

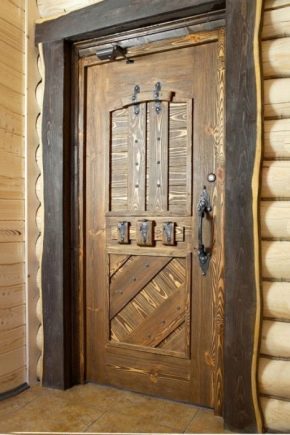

The modern market is oversaturated with various door variants made from various materials. However, the tree remains traditional. Due to its high quality indicators, as well as the property perfectly combined with wooden furniture and floorboard, wooden doors have become more in demand, especially in the interiors of apartments and country houses.

In addition to their aesthetic characteristics, wooden products have a number of other advantages: the strength of the material, ease of processing of the material, the ability to retain heat, good sound insulation, as well as environmental friendliness.

It is worth paying attention to the fact that if the choice fell on a wooden door, then all other parts should also be made of wood (box, platbands, doors).

Among flaws in wood, it can be noted that it is flammable, has the ability to absorb moisture and expand, and, of course, high cost.

The most popular, but not the easiest to manufacture, are framed doors. As internal inserts, it is better to use ready-made cutters, as cutting them yourself is a laborious job. In the construction market you can buy a set of milling machines for the future door. To save on material the door leaf can be made from boards, instead of a wide monolithic canvas.

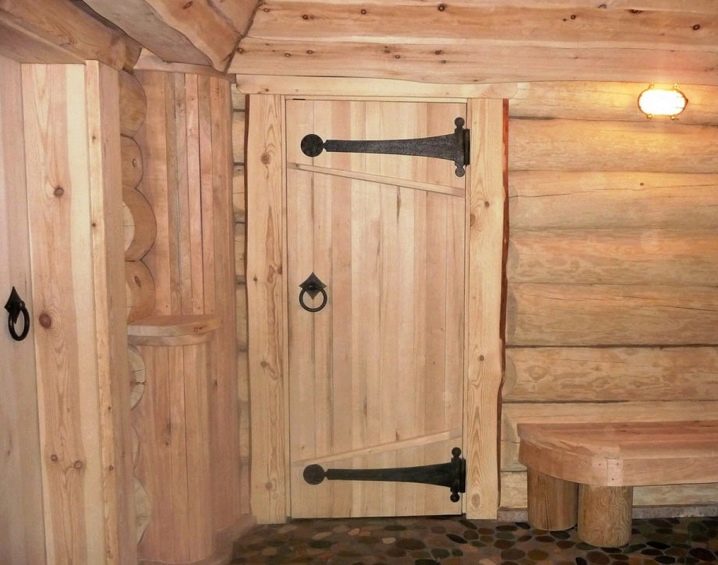

If you need to make the door to the dacha shed or in the bath, you can use even cheaper materials. A good alternative to the wooden array will be a door made of plywood.This is a fairly durable material, in its manufacture, sheets of peeled veneer stick together with each other so that the fibers of one sheet are arranged perpendicular to the fibers of the other. The outer layers of plywood are glued with veneer of aspen, pine or larch (these types of veneer have good strength and aesthetic appearance).

Products from lining - also inexpensive option. The advantage of this material is that in order to make the door, it is not necessary to use the factory lining, you can make separate profiles from scrap materials.

In addition to natural materials, synthetic polycarbonates are widely used. The choice of this material for the manufacture of the door is beneficial to do when it is assumed that the design will be affected by adverse weather conditions (humidity, temperature). But if earlier polycarbonate was used for the manufacture of greenhouses, now it is easily used for entrance doors, the main thing is to provide a reliable basis and insulation.

If desired, you can build a structure of other polymers. Often make an aluminum frame with inserts of plexiglass.It looks quite stylish, but these materials are quite expensive.

How to make a box for the door?

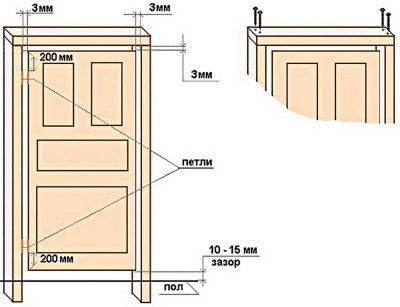

Before you begin to collect the door frame, you need to examine its structure. So, the door frame consists of four main parts: two pillars (the longest parts of it), a threshold and an upper crossbar (short parts). To begin with, measure the length of the racks. In the case of using the threshold, it is equal to the length of the door plus 2-3 centimeters on the gap on each side. If the threshold is not, then instead of the gap from below, add 15-20 centimeters. This will ensure that the door is free from the floor.

The measured values are scribed on the canvas and cut out each stand with a special knife.

Crossbar and threshold - the same component parts. Their length consists of the width of the door, the same two gaps and the thickness of the box. The measured dimensions are transferred to a wooden sheet and cut one or two elements, depending on the need threshold. In the upper lintel of the box, grooves are cut, noting the lines where the stands intersect with the upper crossbar, and carefully cut these areas with a jigsaw on each side.

After all the grooves have been cut, the posts and the crossbar are aligned on the floor to make sure that they fit together.After that, the cut parts are thoroughly sanded with sandpaper, eliminating all irregularities and rough roughness. When all the elements of the box are ready, you can proceed to assembly.

In order to assemble the design, you will need a drill or screwdriver. Insert a drill size of 2-3 millimeters into the screwdriver and drill holes in the aligned corners of the future box. These holes will allow the material to remain intact when the screws are tightened into them. Screws screw into each hole. The door frame is almost ready.

To make sure that the box is made correctly, you need to place it on the floor and put the selected door leaf inside, assessing the presence of gaps between them. It should be noted that if the task is to independently manufacture a sliding structure, then it is necessary to take into account its distinctive mechanism. When opening such a door, it will move aside like a pencil case (enter the wall or lay on it), therefore, when forming the box, you should provide a groove for the door in one of the uprights.

How to make the door itself: step by step instructions

Now consider how to make the door itself.For outbuildings, the door will be a simple shield of individual planks, fastened together by wooden straps. Interior wooden doors should have a more aesthetic look, simple strapping is not applicable here.

Work should be carried out on a carpentry stand or on a table that will allow you to completely place the product on it.

To form a door leaf, grooved boards are used with grooves (you can also cut the grooves yourself). The thickness of the boards should be from 2.5 to 4 centimeters, depending on whether it is an interroom or entrance door. Prepared boards fold into a shield. If the grooved boards are taken, the grooves on the outer boards are removed using a circular saw.

The boards are glued together with carpenter's glue, and the pattern of annual rings must be observed (they must lie in the same direction so that there is no imbalance on the finished product). The blank of the door is placed in a vice in order to firmly combine the elements, and allow the glue to dry out. After that, the milling machine passes the entire surface of the canvas, paying special attention to the joints and uneven fragments.

If the thickness of the boards is not sufficient to use the door as an entrance door, then you can glue the boards in two layers. Such a door will be quite massive and heavy.

Next, go to the design of the finished shield. Using the stencil, they shift the drawing onto the wooden sheet first with a pencil. With the help of a milling cutter with a manual mechanism, the pattern is carefully cut out, changing the cutters. The finished drawing and the canvas itself should be treated with sandpaper, then get wet with a special antiseptic solution. If the door is an entrance door, then it must be treated with moisture-resistant means and flame retardants. So it will serve much longer.

How to insert?

On the door frame mark the place where there will be hinges. On the door leaf, in the appropriate places also make marks. To do this, put it in a vertical position, the top bedet the side where the hinges are attached. On the reverse side mark the location of the castle. Preliminarily, the door is placed in a box, they check the conformity of the marking, mark the location of the tongue of the lock on the box, then insert the hinges, then apply them to the door and to the box, drill them with a drill.The tongue is neatly cut out with a jigsaw.

In order to properly install the door lock, it is first applied to the place of installation on the product, circled, dotted with all the necessary technological holes. After the installation depth of the lock is determined, it is placed on the marked place and fastened. Now that all the parts are ready, you need to install them correctly.

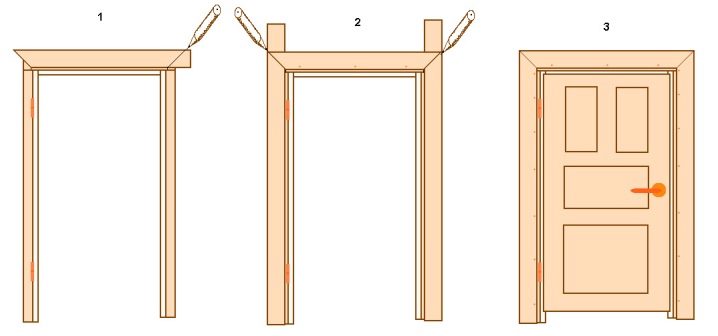

First, insert the door frame into the opening. We align and fasten it with wedges. The box already mounted in the wall can be adjusted by hitting wedges with a hammer. Then dowels and screws are inserted into the holes drilled in the wall and box. And the last, most important thing is the assembly of the door and box.

It is better to perform this operation together, in order to avoid injuries, since the door leaf is a heavy construction. Holding the door on weight, we fix the hinges with screws.

After the assembly of the main parts is completed, it is possible to work out the platbands. It is easier to buy ready-made in the store or to make yourself using wooden blanks with a thickness of 1-1.5 cm and a simple jigsaw. Each edge of the clypeus is cut at an angle of 45 degrees and adjusted in length.Finished products are fixed at box level with wood glue or small nails.

In general, the work on the installation of the door, with the right approach and quality materials, will take no more than two days. And the above recommendations can be used for the manufacture of doors from other materials, changing only some tools.

Finish

To finish the finished product will help finish. It can also be carried out independently; it is more pleasant and less complicated work than the installation and assembly of the door itself. Door trim can be carried out as follows:

- painting the door;

- varnish coating;

- wallpapering or decorative film;

- decoupage;

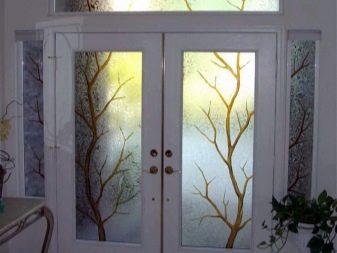

- insertion of mirrors and colored glass;

- fabric lining;

- application of methods of aging of wooden linen.

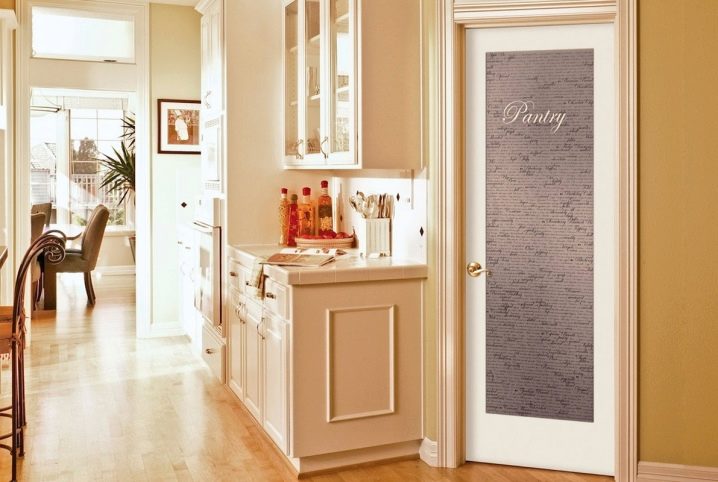

If you do not want to spend time decorating your door, you can simply paint it with ordinary paint or stain, and then, if desired, varnish. Waterproof wallpaper and self-adhesive film is convenient to use if the door is installed in the bathroom, as this will additionally provide it with protection from moisture.If you want to achieve a stylish design, learn the techniques of artificial aging. So even the usual homemade door can be turned into an elegant element of the interior.

Decor options

For those who do not like boring standard cladding options, you can offer more interesting design solutions for product design. For example, door wallpapers. With the help of well-chosen pattern you can make a spectacular door, which will become a bright accent in the room.

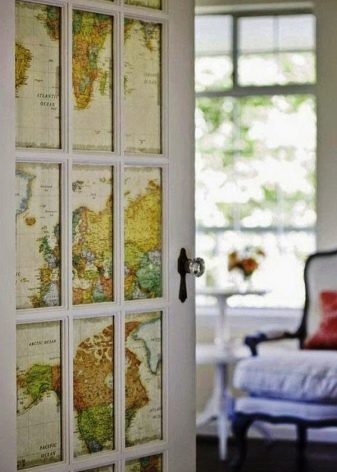

An interesting decoration option is old geographical maps or black and white photographs. Cuttings of articles from newspapers or posters from magazines will also look unusual, casting pleasant nostalgia. You can glue the door colored strip. This option is suitable for a country house or a nursery.

If preferred bohemian stylethen paint the moldings in a contrasting color. Often used stencil patterns. Especially creative people can express themselves and paint their work with oil or acrylic paints, having previously prepared the basis for the door. Children will love the original stickers in the form of fairy-tale characters or comics.

For the kitchen is suitable door decorated with a cloth. But here you first need to study the properties of this fabric and especially its shrinkage. As a glue, ordinary paste is used, based on casein or CMC. It looks interesting door trimmed with leather, nailed furniture studs.

Functionally, the mirror will be inserted, inserted, or glued to the door structure. And for a family with small children, you can skip the scenery altogether. It will arise with the help of skilled children's hands. Cute and fun.

Beautiful examples in the interior

Of course, the main function of any doors is sound insulation, preservation of heat and personal space. But do not forget that the door is included in the list of basic elements that give the appearance of the room a certain style. The color of the door is important for the interior. But sometimes in different rooms the interior is different and you need to choose the door so well that it would be combined with that and with a different style. It is difficult, but there is nothing impracticable.

The main rule in this case is to focus on the overall style of the home. Determine which interior prevails, and select the product in accordance with it.

Neutral color of the door, matched to the color of the floor or ceiling - the perfect way out of the situation when you do not want to fool your head. A good option - sliding design with glass. In almost any apartment, they will be appropriate, regardless of whether it is a classic or high-tech. At the same time for the high-tech style suitable version with a chrome body. You can make a box of metal doors or make metal bundles on its canvas.

If the door is faced with the task of zoning inside one room, then a door-screen with a body of rails and a woven base will be a good choice. Moreover, to make it much easier for any other door, you only need to work on a movable connection of elements. Try to make the door yourself, and your product will become not only the subject of the interior, but also personal pride.

How to make a door with your own hands, see the next video.