Enamel EP-773: properties and application

The purpose of the enamel EP-773 is effective corrosion protection of metal products, used in aggressive alkaline environments. If certain requirements for preparation and painting are observed, this paint coating can create very reliable protection for metal products.

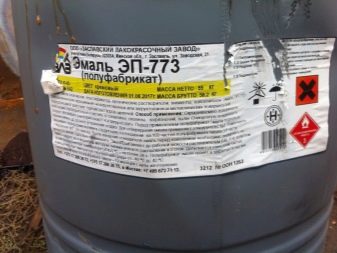

Specifications

The production of enamel EP-773 is engaged in the company PKF "Spectrum". In accordance with the certificates, this coating is intended for painting metal surfaces. This applies to metal products that come into contact with alkalis during operation and operate at elevated temperatures. According to GOST 23143 83 the composition of such dyes should contain pigment substances, fillers and epoxy resin.In addition to protection against corrosion, which should be carried out under the influence of hot alkaline vapors and corrosive liquids on the surface, the paint of this brand should also protect the metal from the effects of mineral oils and gasoline, as well as from ordinary moisture.

Apply this paint and in everyday life to protect metal products from precipitation. Enamel paints well pipes and other equipment, mechanisms, units and technical facilities made from both ferrous and non-ferrous metals.

When applied to the surface to be painted, EP-773 single-component paint creates a smooth coating with a matte or semi-gloss tint. This enamel at 20 degrees completely dries in 24 hours and in 2 hours - when heated to 120 degrees Celsius. The degree of viscosity of the dye is 25–60 arbitrary units.

The consumption of dye per layer is 60–75 grams per square meter with a thickness of one layer of the order of 20–25 µm. To achieve the desired effect it is enough to create two colorful layers.. When adding a hardener, the enamel is able to retain its properties for a day or more. Recommended solvents for this paint are P-646 or toluene.. Before painting, the surface must be primed with the help of recommended primers of the brand EP, AK or VL.

The quality of the enamel coating is due to the amount of anti-corrosion filler in it, with a significant change in the content of which the properties of the dye deteriorate. The paint produced at the Spektr enterprise has cream and green colors, but at the request of the customer, a dye with a number of other colors can be obtained from the manufacturer.

The resistance of cream enamel to the effects of 40% potassium hydroxide solution is 2 hours, and for green paint under the same conditions, this figure is 8 hours. For this reason, when choosing a color, you should consider the recommendations of the manufacturer.

Dye use

If the surfaces to be painted are exposed to heated alkaline solutions, it is better to use green dye to protect them, before applying which EP-0010 or 0020 filler should be used and make sure that the paint structure is uniform and there is no need to add solvent to it.

If necessary, you will need to thoroughly mix the paint and add the attached hardener, the amount of which in relation to the base material is indicated in the instructions for the dye. And It is impossible to change this ratio, since such an imbalance will negatively affect the quality of VC-773. At the end of the addition of the hardener, the composition is mixed for 10 minutes. If it is notable for excessive density, the paint is diluted with a solvent, and it should be used in 30–40 minutes.

The subsequent coloring is carried out on in advance grounded dry surfaces. In a situation when a metal construction will be used in an environment with moderate aggressiveness, it is allowed to apply the dye on a clean surface without prior priming.

Anyway Before painting, the surface of the metalware should be cleaned from rust stains, dirt, dust, traces of oils and other undesirable elements to ensure adhesion of the dye to this surface. Since there is no rust converter in the composition of paint EP-773, it is necessary to remove the latter in advance. It is also allowed the use of sandblasting method of cleaning the surface.

Coloring is performed by the method of pneumatic spraying, and in living conditions a brush or roller is used, although at the same time the consumption of dye per unit area slightly increases. Painting work should be carried out at a temperature not lower than 15 degrees Celsius and at a humidity of not more than 80%.

Drying can be carried out in the usual way at ambient temperature, and with heating the products to be painted up to 120 degrees. In the latter case, the first layer completely dries out in about 2 hours. If the painting is done in a cold way, then the application of the second layer becomes possible only 24 hours after the final drying of the first.

High-temperature drying gives the enamel film greater resistance to the effects of aggressive factors on the product.

Security measures

EP-773 enamel is flammable, therefore its storage and use near fire sources is unacceptable. Coloring of products is possible only with sufficient natural or forced ventilation, as well as in overalls and respirator protecting respiratory organs. In case of dye on the skin, this place should be thoroughly washed with warm water and soap.

Storage of the dye is allowed in the temperature range from –30 to +30 ° C in conditions that exclude the ingress of direct sunlight.

Analogs

If further contact of metal surfaces with aggressive factors is expected, then one should refrain from purchasing cheaper analogues of this dye. The lower price of such dyes is explained by the exclusion of a number of components from their composition, which significantly reduces the protective properties of such paints.

Savings are justified when it comes to painting metal products that will not be in contact with alkalis and other aggressive substances. If such contact cannot be avoided, then the best option for protecting metal surfaces from negative factors is EP-773 enamel.

How to restore the old bath using enamel EP-773, see the next video.