Enamel primer rust: features and application

Enamel primer rust - universal composition. It allows you to solve 2 problems at once: to give the metal product an aesthetic appearance and protect its surface from corrosion. Such paints can be used for everyday tasks and professional use.

We study the description, features, purpose, types of data paints.

Features and Purpose

Anti-corrosion paints have a complex composition. They include components that give enamel elasticity. They become durable when dried.

The main components of these substances are:

- anti-corrosive components;

- organic matter;

- target components;

- alkyd-modified varnish to give strength;

- the pigment causing the color gamut of the product.

Anti-corrosive enamel-primer for metal is used to protect metal products from rust and create a decorative layer on them.

The formulations can be used for clean or corroded metals.They cover equipment and structures inside and outside the room. Thanks to anti-rust paint You can create a reliable protection of metal products from high humidity, water, precipitation. Due to this feature, enamels are widely used in painting gates, roofs, grilles, and various forged products and structures.

They are actively used to cover various machine parts (bottom, wings, sills) or water transport.

Types and characteristics

In search of attracting buyers, manufacturers produce an extensive range of anti-corrosion paint products. It differs in its purpose and technical characteristics.

There are several varieties of such enamels on the market.

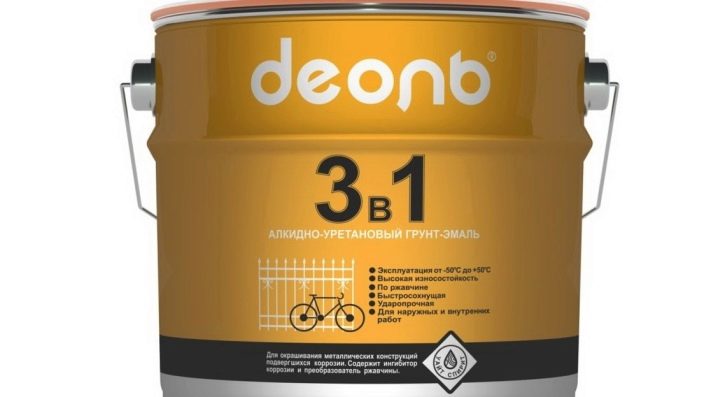

- Alkyd urethane. This paint is designed for processing metal products. However, high performance characteristics allow its use to cover the bases of concrete, wood.

- Epoxy. Due to its resistance to weathering, this composition can be used for painting roofs and exterior walls. Indoors, epoxy enamel is often used to paint floor surfaces.

- Polyurethane. Two-component polyurethane is designed for decorating the floor indoors.

- Alkyd. Universal composition suitable for external or internal use for processing products from any materials.

All presented soil-enamel are divided into several types. They can be:

- insulating;

- transformative;

- passivating;

- phosphating bicomponent;

- inhibiting or protectors.

Insulating compositions when applied to the surface form a layer that protects the product from moisture and oxygen. Due to high heat resistance they are widely used in the painting of structures located on the street or in the water. Converting substances due to the content of orthophosphoric acid form a phosphate layer and contribute to the partial restoration of rusty metal. Passivating paints slow down the rate of the corrosion process.

Phosphating analogues are known for their good adhesion. Due to this, they can be used when painting galvanized products. Enamel protectors contain metal particles that allow you to create a reliable and durable coating. Such compositions are recommended to be used for coloring products that come into contact with water..

Inhibitory materials are known for their excellent adhesion to rusty metals. Their main disadvantage is high consumption.

Advantages and disadvantages

Anticorrosive enamel primer has numerous advantages.

We note the main advantages:

- The convenience of use. The compositions can be applied to treated and untreated surfaces. It is allowed to paint over rusty metal products.

- Excellent adhesion (adhesion) with surfacesaffected by corrosion. The coating will not flake off over time.

- Even protective layer. Paint falls evenly.

- Coating stability to organic and inorganic formulations. The dried layer is not afraid of weak alkaline, saline, acid and alcohol solutions.

- Maintaining low and high temperatures (temperature range is -40 to + 100 ° C).

- Efficiency. The consumption of such material is small. This saves the budget and allows you to perform high-quality coverage.

- Fast drying painted surface.

- Durability applied layer.Paint on treated products indoors will hold at least 10 years, 7 years outside.

- Rich selection of colors. If you wish, you can buy the material in the right shade.

As with all dyes, anti-corrosion compounds have some drawbacks. For example, they can not cover the parts of metal structures in contact with drinking water. Also, the disadvantages include the unpleasant odor of enamels, which lasts for a long time after processing the products.

Colors

Trade marks let out paints and varnishes with anticorrosive effect in a different variant.

The most popular colors of paints today are:

- the black;

- red;

- Gray;

- yellow;

- Violet;

- blue;

- blue;

- silver;

- white.

Some manufacturers offer translucent materials and paint colors chameleon. Among the products presented, consumers will find matte or glossy compounds. This will allow you to choose a coating based on the taste preferences of the buyer.

A separate group consists of hammer soil enamel. Such materials contain aluminum flakes. Due to them, the treated surface visually resembles a metal broken by a hammer.

Consumption

Soil enamels rust are economical. Their consumption ranges from 80 to 120 ml per 1 m² with a layer thickness of 0.02 mm. Usually 1 kg of material is enough for processing 7m² surface. This is about 30% less compared to the rate of consumption of traditional paintwork compositions.

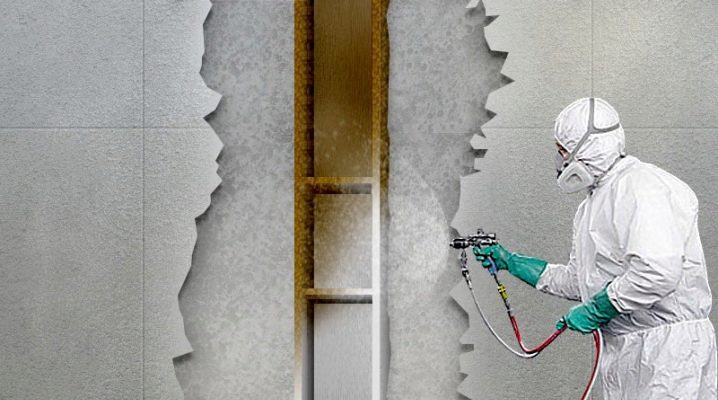

Surfaces in need of treatment are painted using:

- brushes;

- roller;

- spray gun.

The better prepared the surface, the less required composition for its painting.

Manufacturers Overview

The range of anti-corrosion enamels is represented by tens of hundreds of products from various manufacturers. There are several of the best companies that have won the trust of consumers.

Novbythim

Domestic manufacturer from St. Petersburg produces a line of paints and varnishes. Of all the anti-corrosion compositions of this brand produced, quick-drying 3 in 1 “Novbythim” enters the greatest demand. Used as a conversion, priming and decorative material. Used for painting complex structures.

"LKM technology"

Novosibirsk company engaged in the development and production of paints and varnishes.The sales leader of the presented brand became the primer-enamel 2 in 1 "Pental-Amor" and the primer-enamel 3 in 1 "Corroed". The first is designed for outdoor and indoor use. "Corroed" is used for the purpose of repair painting of various structures and objects (spans of bridges, hangars).

Alp Enamel

The manufacturer from the Moscow region offers the primer enamel 3 in 1 Severon to the consumer. This composition is characterized by rapid drying and weather resistance. The material is designed for use in harsh climatic conditions.

"Yaroslavl paints"

The company is engaged in the production of soil-enamel "Special Forces" 3in1. This composition has found wide application in industry. With its help, by painting, they restore bulky objects and structures on which it is difficult or impossible to dismantle an outdated decorative coating. The material is also used to paint various parts of cars and trucks.

Russian Paints

The manufacturer produces paints "Prodecor". Such compositions are indispensable in the repair painting factory objects.They are characterized by high performance and durability.

NGO "Krasko"

Moscow company producing impact-resistant, semi-gloss, quick-drying enamel "Fastmet". The company also manufactures primer-enamel "Polyuretol" containing particles of titanium. Thanks to this component, the coating is characterized by increased resistance to various power loads and mechanical stress.

Hammerite

Primer enamel with a non-standard pattern produced by the Polish company Hammerite. Its composition contains metal components that, when applied and dried, form a surface that visually resembles a coinage.

Tips for choosing

To choose a suitable dye, you should familiarize yourself with the recommendations of experts:

- Initially, you need to consider what material the surface is made of. For example, for galvanized bases need phosphatizing two-component dye.

- Pay attention to painted structures. For products with a complex configuration, you need to choose a paint with a high level of adhesion.

- Consider moisture. With its high rates, it is advisable to use materials with insulating or passivating properties.

- It is important to take into account the air temperature.If it is low, it is better to buy a winter paint, characterized by quick drying.

- It is necessary to take into account the decorative quality of the primer-enamel. Thanks to a rich selection of dyes, everyone can choose the color and texture of the composition in accordance with their individual preferences.

Staining recommendations

Before painting, primer enamel must be thoroughly stirred with a wooden stick or a construction mixer (the choice depends on the volume of the material). If necessary, the composition may be diluted to the optimum consistency with a solvent specified by the manufacturer in the instructions. Before applying the paint surface must be prepared.

Preparation includes several consecutive stages:

- Cleaning the surface from accumulated dirt and dust. For these purposes, you can use a rag and a bucket of water, high-pressure washing.

- Cleaning the product from peeling rust and loose corrosive areas. To remove the layers, it is recommended to use a metal brush or grinder with a specialized nozzle.

- If there are oil contaminants on the surface, they should be removed with white spirit.

- Existing varnish or nitrocellulose composition on the surface of the processed product must be removed. When applying enamel primer there is a high risk of detachment of the old layer.

To eliminate the risk of detachment, it is recommended to carry out a preliminary test: paint a small area and wait an hour. If the surface does not change, you can continue to work.

Before painting it is important to ensure that all conditions for effective and high-quality work are met. The temperature of the ambient air should be in the range of -10 to +30 degrees, humidity - no more than 70%.

If you plan to paint with a brush, it is recommended to pick up a tool with a wide base and natural bristles. It is allowed to use metal spray guns.

The use of plastic sprayers is not desirable. Chemically aggressive substances can damage the plastic parts of the instrument.

During work it is necessary to use protective rubber gloves and a respirator. When painting indoors, the object should be well ventilated to reduce the toxic effects of paint.

Enamel-primer is better to apply in several layers (2 or 3). Before you apply the second layer, it is important to ensure that the previous one is completely dry. Under optimal conditions, the composition dries out within 1-1.5 hours.

Reviews

Primer enamel on rust mainly has positive feedback from consumers. Buyers appreciate its high hiding power, full staining of rusty surfaces without staining and bleeding through of the old dye. Many have identified the cost-effectiveness of the compositions, they do not require preliminary additional treatment with primer. It saves time and money.

Consumers also note fast drying and easy application of the composition due to its good elasticity. Among the disadvantages buyers emit a pungent smell of material that persists in the room for a long time. The use of primer enamel over rust is a great way to create a reliable and long-lasting protection for a metal product against corrosion. However, to prevent premature rusting, you need to choose the right composition and adhere to all the rules of its application.

In the next video you will find the test of soil-enamel rust in frost.