Soil enamel on rust 3 in 1: features and characteristics

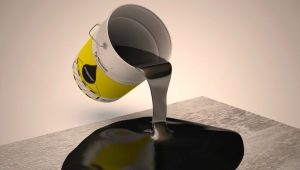

Soil enamel on rust 3 in 1 is a composition with anti-corrosion effect. It is used to protect surfaces and is also used for decorative purposes. Mostly used in the final stage of dyeing clean or rusting metal products.

Special features

Soil enamels of this type are universal blends. They help to update the appearance of metal products. Before applying the paint primer base is not necessary. The enamel itself can perform the functions of a primer.

The primary task of the paint is to stop the spread of rust on the treated products and to prevent the formation of new foci of corrosion. In addition, enamel has a decorative function.It can be made in various colors and is used as a topcoat.

Since various functions are combined in the primer enamel, this makes it possible to apply layers one upon another without first drying. This contributes to saving both time and financial resources of the consumer.

Most often, this composition covers products located on the street. It can be both elements of furniture, and iron gate, garage boxes and other designs. Soil enamels help prevent negative climatic conditions from affecting the material. They endure cold weather, heat and high humidity. However, this does not negate the possibility of using the mixture indoors for processing interior elements.

The use of mixtures in the process of car repairs has become widespread. Most relevant is the processing of its internal components, which are often in contact with liquids such as oil and gasoline, as well as exposed to high temperatures. After the elements are enameled for one or several times, they become inert to the action of aggressive media.

In addition, 3-in-1 enamel primers are widely used in industry. This also contributed to their resistance to aggressive conditions.

The use of soil-enamel is possible not only when working with metal surfaces. In addition to cast iron, aluminum and steel, they are excellent for bases made of brick, concrete and wood.

The universality of the mixture is achieved thanks to its components. First of all, it is based on alkyd-urethane varnish. It includes alkyd resins and urethane additives. Performs the binding function.

The presence of anti-corrosion materials helps to solve two problems at once. The first is the neutralization of rust, which has already managed to hit the product. The second is to prevent new foci of corrosion. This is due to the formation of a phosphate film on the surface.

In addition, the composition has enamel. It is with its help that the finishing layer of the colored element is formed. Due to the plasticizer and similar impurities, the working properties of the mixture are significantly improved. The content of the base solvent helps to preserve the viscosity of the composition.

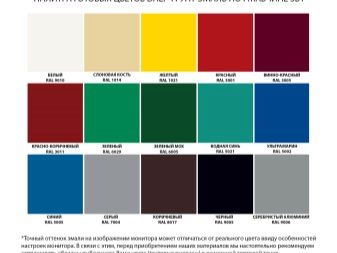

The basis of the primer and additives contained in it, is constantly being improved.This is due to competition between manufacturers. The color range of compositions is quite wide, which facilitates the choice of the consumer.

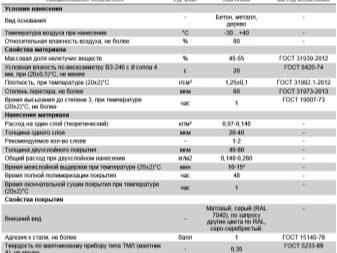

Specifications

The 3 in 1 anti-corrosion compound is dissolved in an alkyne-modified lacquer. The admixture of organic additives and target substances is carried out in the production process. After drying the enamel coating becomes smooth and durable. It has anti-corrosion effect and endures the effects of adverse climate events. In addition, the base becomes resistant to chemicals.

This mixture is an excellent aid in preparing the surface for painting. The coating, created by the composition of rust 3 in 1, is durable, has protective functions and in a temperate and cold climate can not lose them for 8 years. However, this is achieved in the case when the enamel will be applied in 2 layers.

The manufacturing technology of the composition allows to ensure a tight fit of the soil layer to the base. In this case, a layer of varnish will be located on the surface. This is due to special impurities and additives.

The optimum temperature at which primer enamel is applied is 20 degrees. At observance of this condition, the drying of the composition and its properties will correspond to the statements of the manufacturer. However, if there is a need, it can also be used at negative temperature values. After drying, the primer enamel does not lose its qualities in the temperature range from -45 to +100 degrees, which makes it an ideal option for outdoor use.

One of the subtypes of the 3 in 1 rust composition is hammer paint. It incorporates fine metal powder, from this the base after application and drying has a textured rough surface and steel luster. It seems that the product was processed by forging. The mixture also combines the functions of enamel and primer.

It is more difficult to apply hammer paint with a sprayer than a simple one. Usually the work does not do without a roller or brush. If the surface is located vertically, the metal particles can move downwards, which can ruin the final appearance.

However, if you apply paint quality, the elements will look original and spectacular.

Consumption per 1 m2

Calculation of paint consumption on the surface must be made before purchase to save time and money. Regulatory values are specified by the manufacturer. The instruction is placed on the package.

Saving the composition depends on the proper preparation of the base. Opened enamel must be thoroughly mixed and diluted with special solvents or xylene, after which you can prepare the surface for application. To do this, remove dirt and rust from the base, after which you need to thoroughly degrease it. In the case where there is a layer of previous enamel, such as oil or alkyd paint, it should be cleaned. It is forbidden to apply primer enamel over a nitro-containing coating.

Experts advise to conduct a test staining to determine the weak points of the surface, which can later be removed. Allowable temperature for the application of the composition varies from -10 to +30 degrees. Pneumatic spray will help reduce consumption and ensure a perfectly even coating.

It is recommended to apply primer-enamel in 2 layers, making a break for about an hour. When the composition is applied and dried, it can be coated with any paintwork material.

If you follow the technology of application, the consumption of the composition will be about 80-100 milliliters per 1 m2. The number of layers depends on the need and desire of the consumer and can be from 1 to 4.

Manufacturers and reviews

Soil enamel on rust 3 in 1 is offered on the modern market in a huge assortment. Decisive in the selection of the composition should be studied information about the manufacturer, the characteristics of the product, as well as familiarity with the reviews.

Novbythim

The manufacturer packs the goods in packs from 1 to 20 liters. The coating has excellent properties. Paint consumption is quite small.

The price per liter is about 300 rubles, which puts the enamel in a fairly budgetary price category. Consumers say that the composition has a rather sharp smell, due to which it should be used only when carrying out street work.

It is recommended to dilute the paint with a solvent of the same manufacturer.

"Prestige"

The company for the production of this brand is located in the Rostov region.It produces packages of both small and more impressive volume - 20 grams and 1.9 kilograms, respectively. It has a reasonable price.

According to reviews, the composition has excellent anti-corrosion properties and does not cause problems during application. However, there is also a rather sharp smell of paint.

Lacra

Packing soil-enamel of this brand implies the presence of packages weighing 0.8 and 1.7 kilograms. The color spectrum is quite modest. The paint has a low price, copes well with rust and forms a reliable and even coating.

Dali

Soil enamel on rust 3 in 1 Dali is packed in 0.75, 2 and 10 liters jars. Users note its good performance when working with various types of metal and stainless steel, as well as the possibility of using both outside and inside the room.

The paint is characterized by the presence of the hammer effect of the dried surface, which makes it convenient to use it for decorative purposes. The coating is able to withstand mechanical stress, moisture resistant. According to user feedback, 1 liter of the composition covers about 12 m2 of base.

"Rainbow"

Enamel of this brand can cover both clean and rust-damaged products. It has a decorative function.

The coating is obtained semi-gloss, resistant to atmospheric effects, chemical compositions and mechanical loads. On 1 m2 it takes about 70-120 grams of paint.

"Tex"

Hammer mixtures are packaged in containers from 0.5 to 2 kilograms. Regular - from 0.9 to 10 kilograms. Can be used for interior and exterior use.

The paint does not have a sharp odor, due to which it is recommended for use in children's and social institutions. Consumption of 1 kilogram of paint is designed for a surface ranging from 8 to 15 m2.

Tips and tricks

It is not recommended to apply soil-enamel at air temperature above 30 degrees. To reduce the time you can use the sprayer.

Drying the composition and weathering the smell occurs faster in the open air, so it’s worth carrying out work outside or carefully ventilate the room. It is useful to use a respirator.

When selecting enamel, it is necessary to take into account the nature of rusting, as well as the conditions for further use. It is necessary to strictly observe the technology of application, in this case the result of the work will please the consumer for many years.

How to paint the primer enamel, see the video below.