Handmade carpets

Choosing the type of flooring in a residential area, many stop at carpet products. It should be noted that such a coating not only performs the function of floor insulation, it also gives the room a special appeal. Handmade carpets deserve special attention. Handmade products are of good quality and interesting author's design. Such models emphasize the originality and exclusivity of interior design.

Special features

Carpets are considered one of the oldest inventions. They were used for insulation and as a decoration of the house, and were also an attribute of wealth. Carpet making was born at the moment when man mastered the processing of animal hair.

Handicrafts have always had the status of a separate work of art. Each handmade model is unique. With all the desire, the master will not be able to exactly recreate his masterpiece again.

It is worth noting that handmade coatings have a higher cost compared to analogues made in industrial conditions. Currently, however, handmade floor coverings are becoming increasingly popular. Such products can not only add an oriental touch to the interior design, they can serve as an excellent addition to classic styles.

We highlight the main advantages and differences of handmade models:

- durability;

- use of natural ingredients;

- environmental friendliness of materials;

- exclusivity;

- detailed patterns;

- the slope of the pile is in one direction;

- edge asymmetry;

- unevenness in the pattern.

Another distinctive feature of such products is the difference in shades of one color of threads. To describe this phenomenon, the term “abrash” is used, denoting the spectrum of a rainbow.

Kinds

Handmade carpets are divided into three main types: pile, lint-free, made of felt. Additionally, such products are distinguished by their shape (oval, round, rectangular, carpet) and size.

Pile coverings have a complex structure,which makes the process of manufacturing such products more laborious and difficult.

In the performance of this type of coating, three threads are used:

- base thread;

- ducks (forms a carpet knot);

- thread fixing a number of knots.

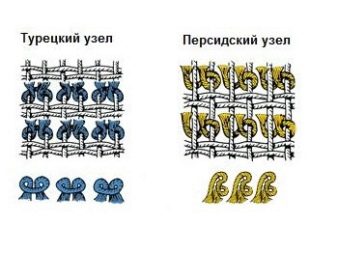

Pile models are divided into knotted and tufted. Nodular products are considered the most difficult to manufacture. At the same time, they have the greatest beauty and value compared to other types made by hand. Nodular products consist of parallel (base), transverse (interweave between parallel and serve as locking nodules) and knotted threads.

The following types of knots are encountered:

- “Giordes” (Turkish double);

- Berber;

- Senne (single Persian);

- Tibetan;

- Spanish.

In addition to the pile in the nodular products there is a fringe. In this case, the fringe plays the role of continuing the carpet. Such products have excellent quality and durability, and the pile fibers are increasingly straightened over time, making the carpet softer.

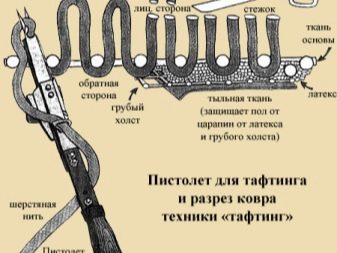

Trapping covers got their name due to the production method. Manual trapping is the insertion of fibers and threads (using a special tool) onto a previously prepared base.An additional base is attached to the back of the product, which holds the fibers together.

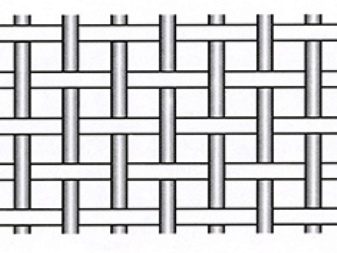

Lint-free cloths are easier to manufacture. In the manufacture of such models are most often used two threads: transverse and longitudinal. The longitudinal thread is the basis of the product through which the transverse thread is threaded - in a certain order.

Lint-free models are divided into:

- sumachs;

- kilims;

- Palaces.

Palace - the easiest and cheapest type of handmade carpets to make. The color palette of carpets is often monotonous (it is allowed to have a striped product). The interweaving of such a model consists of a warp and weft yarns, which makes the texture of the product look like fabric.

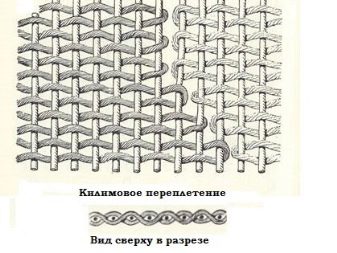

Kilims differ in original design and low cost that makes them popular. The structure of such models contains a variety of ornaments. The pattern is performed by shifting the weft threads of different palettes in a given image.

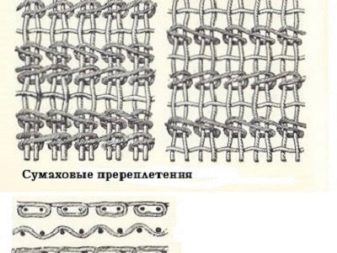

Sumahi - models without pile with various patterns. The peculiarity of this type of coating is that the ornament is created with the help of an additional colored thread. The third thread is conducted around the threads of the base, which forms the texture of the pigtails.The ends of the colored threads from which the pattern is formed are more often brought to the inside of the product. On the back of the carpet there is a kind of thread pillow, which retains heat well.

Additionally, there are handmade felt models. Felt covers are made using wool felting technology. Thanks to this method of manufacturing, the felt webs are of high density and are very warm.

Designer

Exclusive handmade designer models are a separate piece of art. Elite authoring products can be made both on the idea and sketches of the designer himself, and to order (according to the criteria of the buyer). In the manufacture of handmade coatings, designers use only modern and high-quality materials. Over time, such a product will become a real antiques. Antique carpets are exclusive and very valuable interior items.

Designer carpets are made in both modern and classic style. Artificially aged products are very popular. On such models you can see ancient drawings, partially lost images, ancient ornaments, Arabic or Egyptian symbols, non-standard geometric shapes.Properly chosen author's model is able to emphasize almost any interior design, to convey its originality.

- Designed aged carpet with an ancient ornament in the living room interior.

- Model with artificial rubbing in the kitchen in modern style.

- Author's product of the original shape with a wool pile.

- Modern designer model in the interior of the loft.

How to weave carpets by hand?

Handmade models are mainly made from sheep wool, silk and cotton. Sheep wool is most convenient in work, durable and has a low cost. Craftsmen sometimes use goat or camel wool, which makes the pile of the product more brilliant. Silk is the most expensive natural fiber, so it is used in carpet-making less often. Cotton is most often used to produce a carpet base.

According to the method of production of cloths, the following classification is applied manually:

- Wicker. There are knots on the threads of the base. Such products have a pile of various lengths and fringe.

- Woven. Weft yarns and warp twist on a loom. Pile woven products missing.

Consider the example of nap patterns, how to make carpets by hand.Manufacturing technology has not changed much over the centuries. Initially, the master is determined with a pattern and with the parameters of the product (size, shape, number of threads for the warp and weft). Then comes the preparation of the wool.

The quality of the carpet as a whole will depend on this stage. Sheepskin is cleaned from dirt, scratched and painted. After processing the wool is spun. So get the threads for weaving.

Then the master makes the product itself, using the technique of weaving or weaving. The finished product is cleared of the remaining threads and dirt, the field of which is subjected to drying. The final stage is the alignment of the pile height.

How to define manual work?

Knowing the features and technology of handmade carpet weaving, one can easily distinguish them from machine-made products. To avoid counterfeiting, choosing a model of manual production, you should pay attention to the following details:

- Fringe in products made by hand, not sewn to the canvas, but is its continuation. On carpets that are made by machine, the fringe is always sewn.

- Nodules Hand-made models have knots at the base of the pile, since the pile is completely knit by hand.

- Edge winding (except for oval and round models).The side winding of the edges of handmade products is uneven. In machine work goods, stitches are uniform and have the same indentation.

- Marking. On products of machine work there are stripes with information about the manufacturer, serial number and composition. On handmade canvases such tags are almost always absent (on some products near the fringe the author’s signature is indicated).

- Defects and unevenness in the ornament. Making carpets by hand, craftsmen often skip small details in a drawing.

- Material. In the manufacture of carpets by hand, preference is given to natural materials. Synthetics are mainly used in machine manufacturing.

- Colour. Handmade threads often have an uneven color (different shades of the same color).

It is worth paying attention to such things as flexibility, drawing on the reverse side, the combination of materials, the direction of the pile. Handmade products are more flexible (due to the lack of adhesive base), and they can easily be bent in half. The pattern from the inside of the carpet is clearly visible and repeats the pattern on the front side. Pile has a slope in one direction, so the handmade canvas has light and dark parts.

Manufacturers

The very first centers of carpet weaving were created in India, China, Iran and Pakistan.Today, the production of carpets in many countries around the world.

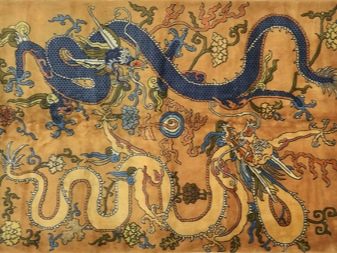

China is one of the first countries where carpet weaving centers were created. Traditional Chinese coatings are distinguished by a large floral pattern and high pile. Among the modern models can be found canvases of various forms and materials - with national patterns (yin-yang, dragons, hieroglyphs). Popular Chinese coatings with embossed haircut pile. Thanks to the use of such a technology for cutting a pile, the image on the carpet turns out to be voluminous.

Carpet weaving has no Indian roots, but it has a long history of development in this country. The first carpets were made under the explicit Persian influence, but later handicrafts began to show their national features.

Wildlife, animals and birds were most often used as patterns. When choosing a material for the manufacture of goods, the craftsmen mostly choose silk. Handmade Indian silk models are of high quality. The appearance of such products does not deteriorate over time.

Certain families and whole craft dynasties were originally engaged in making carpet in Iran.The drawings on such products reflect the local culture of the country and folk customs. Iran to this day remains the leader in the production of carpets. Iranian carpets are often sold under the name "Persian".

Pakistani carpets are made mostly of wool. Floral and geometric patterns dominate on carpet products. Pakistani carpets are divided into single-level and two-level. Products related to the first type, soft and easy to bend.

Two-tier models have greater rigidity and durability. The distinctive shades of Pakistani flooring are gold and red (these colors are present in every carpet product).

We should also highlight handmade carpets from Nepal. The color scheme of Nepalese products is light. Such carpets are ideal for creating a warm atmosphere in the room.

Nodes in Nepalese products are located tightly to each other. After the master completes the weaving process, the product is subjected to careful processing (the surface of the carpet is washed). Thanks to washing, patterns on carpets acquire a rich shade, which is the hallmark of Nepalese products.

In this video you can see the process of producing handmade silk rugs.