Features hammer paint for metal

Nowadays, there are a huge number of colors that can be selected for a variety of materials. In the past ten years, decorative coatings have become in great demand, among them - paint with a hammer effect. It is not cheap, but it has a number of unique properties that should be considered in more detail.

What it is?

Hammer paint is ideal for the decoration of metal products. It gives an aesthetically appealing look even to rusty details. It is difficult to find a more effective protection against the harmful effects of moisture and temperature differences.

At the heart of hammer paint - synthetic resins, as well as metal additives; This explains the good resistance to environmental influences. Also in the hammer substance is added:

- silicone;

- aluminum powder;

- crushed glass;

- some other factions.

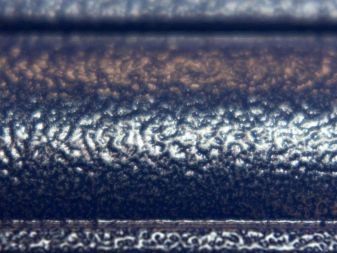

Hammer paint has a remarkable property - it is able to hide irregularities and flaws on the surface of products. Due to the presence of aluminum and silicone, the substance dries out and gives the surface an original, aesthetically appealing look. In this case, the resilience of the treated material increases many times.

It is desirable to carry out the work at temperatures from 5 to 36 degrees Celsius.

It should be noted that the hammer paint in its technical characteristics is very similar to the polymer coating, which is much more expensive.

Sometimes unscrupulous manufacturers selling hammer paint under the guise of a polymer composition. At the same time, the hammer paint itself is often forged, there is a large percentage of counterfeit on the market. When purchasing a product should not be guided by criteria such as low price. Chances are that this substance is not Hammer. When choosing, pay attention to the manufacturer, make sure that the certificates are authentic. Statistics says: more than ¾ hammer paint on the market - fake.

Special features

Hammer coating characteristics may vary from manufacturer to manufacturer, but on average they look like this:

- density - 1 kg / l;

- diluted with white spirit solvent;

- the binder is an alkyd resin;

- surface residue - 48% of the volume;

- dries at least two hours;

- each subsequent layer is applied in five hours;

- stored in containers up to two years;

- resistance to temperatures up to 80 degrees Celsius;

- gloss level - 66;

- consumption - an average of 1 liter per 9-10 square meters (one layer).

Main advantages:

- before processing a paint like metal, it is not necessary to thoroughly clean it from rust;

- the coating layer tolerates vibration, atmospheric phenomena;

- the coating effectively protects metals from rust;

- the treated surface does not require repainting up to ten years;

- the coating resists high temperatures, so this paintwork material is often used to paint fireproof cabinets and bank safes;

- hammer substance does not contain toxins, which have a detrimental effect on the human body;

- the dye does not have repulsive pungent odors, it can be used even in those rooms where there is not too good air flow;

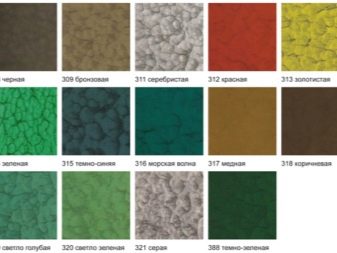

- rich variety of shades;

- a layer of hammer coating after application for a long time "holds" the color and does not fade;

- dirt and dust do not stick to the painted surface.

Hammer paint looks very advantageous in appearance, forged metal products look especially impressive.

Recalling the shortcomings of hammer paint, we can mention the high price. A kilogram of such a mixture costs more than one thousand rubles. In addition, it is possible to remove old layers from the surface only with the use of considerable efforts and strong solvents.

Colors

Hammer paint does not really need primer coats. Its remarkable property is that it itself has the ability to effectively penetrate the coating, because the colors remain in their original form for a long time. It is necessary only before work to properly prepare the surface, cleaning it from dirt, dust and old paint.

Hammer dye has a high adhesion coefficient.It does not interact with water, therefore, metals coated with such a composition do not rust for a long time, while maintaining uniform tint.

The coating does not deteriorate under the influence of ultraviolet rays. Manufacturers ensure that the coating will not fade over a quarter century. There are also reasons to state: painting withstands mechanical effects. A metal can be deformed by a hammer, but the paint layer will remain unchanged.

There are several varieties of hammer paint.

- ML-165. Designed for painting the surface, which is completely free from oil and other fats. Good withstands high temperatures. With very strong heat can release toxins. The following colors are especially often used: black, gray, golden.

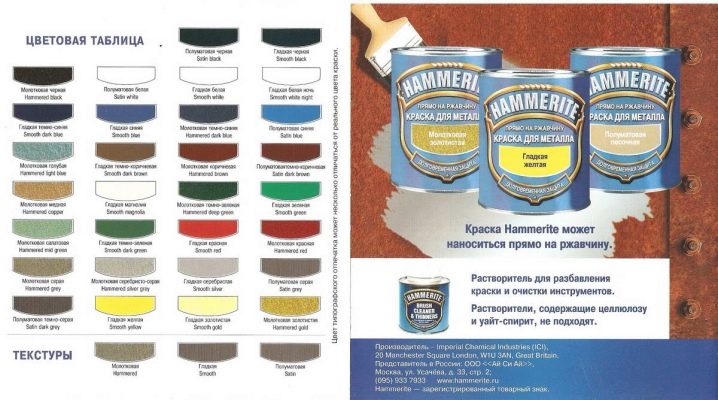

- Hammerite - hammer paint of the highest quality, extremely effective, is not cheap. It has a wide palette of colors.

- NTs-221. For the price it is the cheapest hammer paint, it is recommended to be used when working in rooms. Does not possess such effective properties as the first two types, however, is quite effective. Consumption - liter per 4 square meters.On sale there are all the primary colors.

Application area

Hammer-type dyes are widely used in the repair and manufacture of home-made metal products, including forged ones. Outside, they are primarily used to decorate fences and other similar structures. In the premises, hammer paint is most often used for processing:

- various techniques and equipment;

- metal assemblies in various building structures;

- furniture;

- metal fences;

- pipes;

- ceramic tiles;

- glass products.

Surface preparation

Before starting work, clean or thoroughly wipe the surface. To do this, apply a variety of solvents, acetone or "white spirit." The degree of surface readiness is easy to check, if you hold a sheet of thin paper over it - there should be no traces. If they are, cleaning should be repeated.

Sometimes a metal brush helps a lot, because by cleaning the surface with such a tool, you can significantly increase the adhesion coefficient. The substance fits well on the old paintwork material, which is not necessarily cleaned to the ground, you just need to remove "burrs" with emery paper.

It is also good to hammer paint galvanized and aluminum surfaces, as well as nodes made of non-ferrous metals.

The only condition: Before work materials should always be treated with a primer. If the hammer paint is applied to wood, then it is pre-treated with an acrylic primer. When it dries, it creates a film on which the coating will adhere to an even durable layer.

Work recommendations

The substance can be diluted with a nitro 646 or 645 solvent. The solvent itself cannot affect the quality of the coating or the gloss. Before starting work, the mass should be thoroughly mixed so that the composition is as uniform as possible in concentration.

Apply the dye using spray cans, roller, brush or pneumatic spray. It is important not to make a layer of paint too thick, in normal its thickness is about one hundred microns. This density is optimal for reliable protection of metal and wood products.

The use of aerosol is appropriate when it is necessary to paint a small part of the surface.

Before starting work, it is recommended to shake the can sharply. Consumption of the substance in the cartridge is not visible, so you should apply one layer and wait twenty minutes until it dries. Spray becomes much easier when the amount of substance in it decreases, you should pay attention to it during operation.

When the surface area is large, a special device is used - the spray gun. Its use requires that a substance has a certain thickness. A diluent is used for dilution, adding it in a ratio of 2: 1. This combination is appropriate at a temperature of about twenty degrees Celsius, but if the temperature is lower, then the proportions are adjusted. To treat various parts of the machines, protecting them from rust, the paint is diluted with a solvent in the ratio of 9: 1.

It is better to keep the sprayer at an angle of 90 degrees relative to the treated surface. We must not forget about individual protection. Be sure to use the following order:

- glasses;

- gloves;

- good respirator.

In addition, you should take advantage of a few more tips from experienced professionals.

- It is recommended not to dip the roller into the paint, but to pour the substance onto it in small portions, and then roll it out.

- It is not recommended to use foam coatings for rollers, otherwise the paint will simply destroy the foam.

- The second layer can be applied only after the first one dries.

- A brush is desirable to apply layers only on those surfaces that have a complex configuration. If the dye is applied with a brush on smooth planes, gaps will inevitably remain.

- More substance needs to be consumed at the joints and welds, since these nodes are the most vulnerable.

- It is better to paint over the designated areas in one cycle in order to avoid the appearance of unwanted streaks.

- During the work should not be in a hurry, it is important to handle each carefully, even a small area. It is also important not to use too much substance, so that there are no large layers.

Manufacturers and reviews

Hammer compositions of domestic trademarks in their characteristics are often not inferior to foreign analogues, although at a price they are much cheaper. In this case, the most famous global manufacturer of hammer paint is the company Hammerite. Even unprepared surfaces can be treated with this compound.Even a fairly rusty metal products such paint can change beyond recognition. At the same time, Hammerite coating is a reliable protection for any material.

Such paint dries quickly, it is easy to prepare with the addition of solvent, it is comfortable to work with it. Before starting work, it is recommended to apply a layer of primer on the surface to be treated. - it will increase strength and will give additional guarantee that the coating layer will be more reliable.

The allowable air humidity when working with Hammerite is 80%, the temperature can be from 8 to 26 degrees Celsius. It is forbidden to work outdoors with a similar composition when it is rainy or foggy weather.

The paint “sets” fairly quickly - two hours are enough for this, but the final drying occurs only after two weeks. To get the desired effect, usually apply several layers (up to 5). The time interval between the application of layers is 6-8 hours.

If you want to increase the reliability of the coating, do not neglect its pretreatment. It is recommended to use as much as possible the solvent of the same brand.

Hammer paint is quite popular and in demand, you can buy it at any specialty store. The reviews about it are positive, especially the summer residents, who treat the fences around the houses, various metal parts, garden tools, praise this composition. Everyone notes the lack of smell in this composition, its good adhesion.

Many like hammer embossing, which appears on the product after the paint dries.

A good example of the use of hammer paint, see the following video.