Features of heat-resistant paint

Heat resistant paint is used to paint hot surfaces. It has some features in comparison with the usual coloring composition.

In a private house, heat-resistant mixtures paint stoves, fireplaces, barbecues.

Special features

Conventional paintwork materials used in premises are operated at small temperature fluctuations. Heat-resistant paint can withstand high temperatures without deteriorating the appearance of the surface.

Heat-resistant paint can be called if it can withstand the minimum temperature limits of 100 degrees.

The heat-resistant layer creates a plastic, reliable, vapor-permeable film on the material that wears a protective and decorative function. Depending on the material of the heated surface, the temperature rises to 900 degrees at the place of combustion.The temperature load on the walls of the structure is 600-700 degrees. This is taken into account when choosing heat-resistant compositions.

The use of heat-resistant paints allows to achieve the following tasks:

- protects the metal surface from oxidation and rust;

- permanently protects the material being painted, prolongs the life;

- forms the strong moisture-proof film resistant to attrition and washing;

- under the influence of heat and temperature drops, the coloring layer does not bubble, does not crack, does not fray;

- the painted surface gets the necessary color;

- helps to hide surface defects;

- staining prevents the destruction of the material under the influence of aggressive chemicals released during combustion;

- surface acquires electrical insulating properties;

- helps to comply with fire requirements, as the heat-resistant layer increases the fire resistance of the material, reduces the deformation of the structure during heating, improves heat transfer.

The paint acquires its heat-resistant properties due to its composition. The silicon-based dye mixture contains fillers, coloring pigments, and artificial polymers.Such a component as aluminum and zinc powder allows to improve the heat-resistant properties of the coloring solution. Adding organic resin will improve adhesion with the material, increase the elasticity of the layer and the drying time.

Heat-resistant dyes are used not only to protect the heated elements, but also for decorative finishes, to make the whole room attractive and unique. With the help of thermal painting, you can realize complex design projects.

The negative aspects of this paint include:

- long drying time;

- acrid suffocating smell;

- non-ecological composition.

The coloring composition acquires its strength with the proper implementation of the technology of dyeing. An important component is the preparation of the painted surface., its cleaning and dusting. The paint consumption depends on the choice of the method of applying the coloring mixture. For applying paint, spray, roller or brush is used. Staining in two layers will increase the reliability of the coating. It is impossible to paint the warmed surfaces above 40 degrees. Failure to comply with this requirement will lead to cracking of the coating and deterioration of quality characteristics.

Kinds

Heat-resistant varnish, fire-resistant enamels and paints are used for thermal protection. Do not confuse flame retardant and heat-resistant mixture. Ognebiozashchitny paint protects against fire and suppresses the fire by the method of expansion, with the formation of sulfur dioxide and foam.

All heat-resistant paints are divided according to a number of parameters:

- in composition;

- on packing;

- on the level of temperature exposure;

- on the material of the working surface.

Thermo-resistant dyes differ in the main component composition:

- alkyd base maintains +120 degrees;

- epoxy resin makes +200 degrees, bronze powder enhances its heat-resistant qualities;

- silicone paint with the addition of polyurethane heat resistant to +600 degrees;

- organic silicon with aluminum powder able to withstand up to +1000 degrees, silverfish significantly increases its heat resistance;

- silicate component with the addition of zinc powder transfers the temperature from +200 to +400 degrees.

Depending on the area that needs painting, the packaging and its size varies. The smallest volume is a balloon containing 400-500 ml of dye. In the banks spill from 0.4 to 5 kg of the mixture.In buckets the volume of 10, 20, 25, 30 kg. Over 40 kg of the coloring mixture is poured into the barrels. The instructions indicate consumption rates for different surfaces.

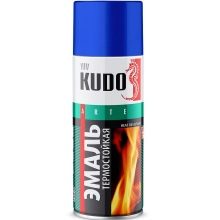

Paint in spray cans allows you to not use an additional tool for the application. Aerosol is preferable when you need to paint a small area and hard to reach places. Thermal spray aerosol does not need to be diluted, and hermetic packaging will not change the consistency of the composition over time.

For painting large areas, it is more convenient to use a can of paint. Rust spots, weld seams better brush over.

The temperature level of the heated surface of the paint is divided into:

- high temperature;

- heat resistant;

- fire resistant;

- heat resistant.

At a temperature of operation from +80 to +200 degrees, a household high-temperature variety based on acrylic, alkyd and epoxy resin is used. Apply it to batteries and radiators. Heat-resistant varnishes withstand temperature effects of 200-400 degrees, used for the treatment of mineral surfaces. It is also added to heat-resistant enamels.

For heat-resistant silicon and silicate compositions, the temperature limit is up to +600 degrees. Fire resistant type can withstand temperatures of 600-800 degrees.Silicone and silicon are used to increase the resistance to fire. Heat-resistant paint can withstand heat in the temperature range from +800 to +1000 degrees.

Types of heat-resistant compositions are distinguished by the type of painted surface:

- on metal;

- on the mineral surface;

- universal paint suitable for any coating.

Paint on metal has good adhesion with steel, stainless steel, cast iron, aluminum, titanium. The composition includes components that increase the corrosion resistance of the metal. Since metal products have high thermal conductivity, the temperature limit of these paints is from +600 to +1000 degrees. For the staining of stone, brick, concrete, asbestos, reinforced concrete used compositions on mineral surfaces. Its average temperature resistance is +300 degrees.

Universal dyes can cover metal and mineral surfaces, they are suitable for wood, glass and fabric. When processing wooden surfaces, pre-applied primer to reduce paint consumption. It is impossible to apply the composition on plastic, only if it is not heat resistant. Versatility allows the paint to be in the average temperature range from +200 to +600 degrees.

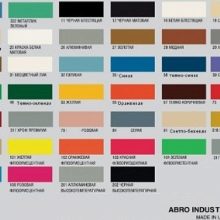

Colour

The most popular and available color is black and silver thermal paint.The temperature stability of the dye and its cost change from the coloring. Black color exhibits the highest heat-resistant qualities.because the dark surface warms faster. White, blue, green paint can withstand a short heating of 600 degrees. Red and yellow paint reduce the temperature resistance of the coating by another 200 degrees.

The degree of saturation of the colors are glossy and matte coloring compositions. If you need to paint over defects and irregularities on the heating element, then matte effect will do.. Such surface transfers heat well, the room warms up faster. The shiny glossy surface of the fireplace will look good and become a bright central decor in the room. The glossy copper chrome in the interior will look impressive.

How to choose?

If you need to paint a heat-resistant surface, then choose heat-resistant dyes.

They are selected according to several criteria:

- surface type;

- temperature, which is able to make a paint coating;

- characteristics of the coloring composition;

- smell;

- drying time of each layer;

- Colour;

- method of application.

When choosing a heat-resistant mixture, you must consider the material of the treated surface. For painting steel, iron, cast iron, paint is used for metal. The dye composition of mineral surfaces paint bricks, stones, concrete. Also sold universal dyes for any type of surface.

Depending on the temperature level on the painted product, dyes are selected with a degree of heat resistance in the range of 100-1000 degrees. In the case of heating up to 300 degrees, thermal paint is used to paint brickwork, car parts, radiators of the heating system. Universal formulations withstand heat up to 450 degrees. Aluminum powder is added to paints from 500 degrees. Heat-resistant dyes from 600 to 800 degrees are chosen for metal heating structures and cast-iron elements of the furnace. Fire-resistant type of heat-resistant paints with a temperature resistance above 800 degrees paint the surface in contact with an open flame.

Technical characteristics of the coloring composition take into account when the coating is operated in specific conditions. When painting boilers in a bath or sauna, the ink mixture should have moisture-resistant properties.In conditions of high humidity and hot steam for the metal are important anti-corrosion characteristics of the dye.

A significant requirement when using heat-resistant dyes is the level of chemical odor. When painting in residential areas, it is better to buy paint for indoor use without the smell of toxic solvent.. On the street, where there is good ventilation, you can use caustic compounds.

Sometimes the drying time of each layer and the time of commissioning the painted surface is crucial. This is important if the work is carried out remotely and there is no possibility of re-departure to the object.

Standard colors for thermal paint are gray and black. But if the interior is important color solution, then pick up the mixture of the desired shade. But compared to ordinary paints, Thermo has a small range of colors and there is no possibility of tinting..

It is also necessary to decide on the method of applying paint - by brush, roller, spray. Depending on this, the paint is purchased either in a can of the required volume or in a can. For coloring large areas choose a dye in the bank. For remote small parts and elements suitable aerosol spray bottle.

Application area

Heat-resistant paints are widely used in the machine-building, chemical, metallurgical, and oil and gas industries. They are also used in the energy complex and fire-fighting decoration of evacuation routes in civilian buildings. They are used for painting heating elements and heating metal structures in factories or in private ownership.

Since heat-resistant compounds have weather-resistant characteristics, They can be used to paint the main heating and gas pipes, moving parts of transport. Often covered calipers, silencers, car drums.

Heat-resistant dyes in the heating system are used for the protective treatment of pipes, chimneys, radiators, fireplaces, brick stoves, heat exchangers, metal boilers and stoves. An additional protective heat-resistant layer is covered with cast iron casting elements - handles, doors, frames, dampers.. For these parts, select the appropriate temperature effects of paint from +600 degrees.

In home use, paints can be used to cover electric and gas stoves, electric dryers, boilers, water heaters. For heating boilers and elements in the steam rooms, saunas and baths, only heat-resistant dyes are used. For the treatment of wooden structures used heat-resistant varnishes. For painting braziers, barbecues and grills, they acquire compounds that are resistant to elevated temperatures up to +800 degrees.

All heat-resistant dyes for metal have anti-corrosion properties. They can be painted on rust, pre-cleaned from crumbling particles. If you need to paint the heat-resistant glass, then the instructions for the paint should indicate that the composition is suitable for glass.

Compositions for concrete and ceramics withstand temperatures of +300 degrees. These dyes paint brick chimney pipes, stoves and fireplaces of brick, stone, granite. For mineral surfaces, paint consumption is higher.

Special alkyd heat-resistant compositions with the addition of reflective particles are used for road marking. The colored layer has an increased resistance to abrasion, chemicals and moisture.At night, the ink marking serves as a reflector of light for the headlights of vehicles.

Manufacturers and reviews

In the Russian market are heat-resistant compositions of domestic and foreign manufacturers. Between themselves, they differ in the cost of the final product. According to consumer reviews, modern paint and varnish heat-resistant dyes of Russian companies are not inferior in quality of manufacturing to foreign analogues.

Among Russian manufacturers can be identified brands Certa, Elcon, Kudo, "Thermics".

The company "Spectrum" produces 7 types of heat-resistant products under Certa brand. Heat-resistant paint that can withstand temperatures up to +900 degrees, has 34 shades. The high margin of safety allows the use of paint in industrial construction and the production of complex technical devices in the automotive industry for household appliances, metal and brick ovens. The stated lifetime is 15 years.

A renowned manufacturer of specialized coloring compositions for industry is Elcon company. Enamels from this brand are designed to paint surfaces that are operated at temperatures from -60 to +1000 degrees.Coloring can be carried out inside and outside the room. In the production of 11 types of heat-resistant enamels designed for different types of surfaces. You can choose among 20 manufactured colors. It is resistant to salts, oils and gasoline. The manufacturer claims about 25 years of service of the finished coating.

The Russian company "Trol-Auto" produces aerosol paints under Kudo brand. These quick-drying silicon-based enamels are able to tolerate heating up to +650 degrees.

LLC Thermika is a supplier of heat-resistant enamels and varnishes under brand "Thermics". The product line includes 4 types of heat-resistant varnish and 9 types of heat-resistant enamel. Heat resistance is up to +600 degrees. Suitable for painting metal and mineral surfaces. "Thermal" KO-8111 is produced in 12 colors. The coating exhibits frost-resistant, hydrophobic and anti-corrosion properties.

Among the foreign manufacturers have proven themselves Finnish concern Tikkurila, American company DuraCoat, Lithuanian supplier Hansa, company from London Bosny, German company Meffert AG Farbwerke. The famous Finnish manufacturer of paints and varnishes produces a line of heat-resistant dyes under the Termal brand.In the sale of heat-resistant painting alkyd compositions of two colors - silver is designed to heat up to +900 degrees, black withstands +400 degrees.

Manufacturer DuraCoat produces unique specialized dyes DuraHeat 2.0. Composition based on silicone allows you to create a heavy-duty refractory film that can withstand heat of +1000 degrees. It is used to cover metal products of motor vehicles, heating elements, firearms, not suitable for painting plastic and wood. It is distinguished by special reliability, resistance to chemical and mechanical stress. The manufacturer gives a guarantee of 100 years of service.

Hansa paint able to withstand temperature effects up to +800 degrees. The line includes 16 shades. The manufacturer recommends using your product for domestic purposes, for painting chimney pipes, various types of fireplaces, stoves and grills.

English brand Bosny It produces two types of enamel dyes - with resistance to temperatures of +650 and +200 degrees. The Bosny feature is versatility, the composition is applied to various types of surfaces - metal, glass, wood, plastic, fabric, ceramic. Packaging - only in the form of an aerosol.

The company from Germany Meffert AG Farbwerke produces paints under Dufa brand. The heat resistant variety is the white enamel "Dufa Heizkorperlack" for painting heating elements. Keeps its decorative qualities up to +200 degrees.

According to customer reviews, some compounds polymerize and acquire their heat-resistant properties when the surface is heated above +200 degrees. It is not always convenient to follow the technological instruction for household use. Some paints are not resistant to chemical solvents.

To learn how to paint the brazier with Bosny heat-resistant paint, see the next video.