Criteria for choosing paint for metal

When choosing paint for metal, you need to take into account many criteria, ranging from the place of painting and ending with the necessary shade. Fortunately, there are many options on the market, and there are plenty to choose from.

Special features

Metal is one of the most common materials, which is why paints must meet several specific requirements. The first is a high degree of adhesion. The paint must adhere well to the surface, not fall off over time. It is also important when choosing to pay attention to the heat resistance of paint on metal. For this indicator limit the scope of the compositions.

For example, some paints can not work indoors, and some cracked and destroyed by high temperatures.

Scope of application

Metal is used in all areas.It is not only about homes, but also about cars, ships and so on. For each environmental conditions you need these or other colors. In everyday life, paintwork materials for metal are most often used to paint roofs of different materials (for example, metal tiles), furnaces, doors, fences, or other metal structures, as well as for interior decorating. Depending on where the metal surface is located, colors are also selected.

Outside

External works: painting of hedges, roofs, various metal elements of pipes or other structures. When choosing suitable compounds, it is necessary to pay attention to their resistance to environmental influences: burnout under UV radiation, the ability to withstand high humidity or temperature differences. The toxicity factor is not so important, except for a number of cases: for example, it is impossible to paint drinking water pipes.

Inside

For paints on metal for internal work more stringent requirements. Here, first of all, their safety is important. Toxic formulations cannot be used, otherwise the health of people and animals in the room will be at risk.Also plays a role and a decorative component. If non-striking universal tones are more often used for exterior work, then brighter solutions are chosen for interior finishing.

The heat resistance of paints and varnishes comes to the fore. In some cases, not only high resistance to elevated temperatures is important (for example, when painting furnaces or radiators), but also non-inflammability.

Kinds

There are many types of paints for metal, each of which has a certain set of characteristics. Some of them are quick-drying, others are suitable for painting galvanized metal. Paint on metal is wear-resistant, anti-vandal, waterproof, chemical resistant, acid-resistant. Such options are resistant to the effects of a substance or to mechanical damage, as can be seen from the names. There are materials with the addition of additional substances (for example, zinc-containing compounds). Let us consider in more detail each of the types.

Inhibitory

Contains in the composition of inhibiting additives. The solution can be applied directly to rust. It neutralizes the oxidative process by stopping it.The covering as a result turns out equal, strong. Material consumption will be quite large due to the need to apply thick layers.

Inhibitory primer enamels are mainly used for outdoor applications.

Stabilizing

The compositions do not convert rust, but only prevent the further development of corrosion.

Epoxy bitumen

The compositions are similar to rubber. They are used for outdoor work. Suitable for painting metal with zinc coating. Paints prolong the service life of metallized surfaces, increase their durability. However, paints in this category are quite expensive, so they are rarely purchased for domestic use. Most often, the use of such compounds found in the automotive industry: they paint the details of the body in order to make them matte.

Silicone-based resin

Materials from this category are distinguished by the greatest indicator of thermal stability. They can withstand up to 600 degrees, as a result of which they can paint, for example, stoves, chimneys and other elements exposed to constant high temperatures. Some varieties are designed to protect surfaces from additional moisture.The range of application is extremely wide: you can paint both barrier elements of bridges, water towers, and any medical devices.

Nitrocrash

Another and more familiar name is aerosol. The option is great for painting small metal areas. Due to the specific method of application, the composition does not flow, there are no stains, the surface is uniformly colored. It is not worth using such paint on large areas: its consumption will be extremely high.

The negative point is that the nitro materials eat off all painted coatings.under them. Also, not all devices are suitable for work: for example, you can successfully use the spray gun or brushes, but you can not use rollers with foam coats, as nitro paint will destroy them.

Pentaphthalic

This type of paint can not be called weatherproof: it is possible to use pentaphthalic compounds only indoors. Solution well protects metal from corrosion, it is moisture resistant and durable. After drying, the color of the paint does not change and does not tarnish, and is not lost over time.The variant has a high elasticity, but at the same time it dries quickly.

It is characterized by good adhesion with metal surfaces.

Rubber

Rubber paint refers to the universal. It can be used for both interior and exterior work. The variant refers to frost-resistant: even in winter, it does not crack and does not lose its qualities. Often rubber or rubber compounds are used to paint the roofs: it additionally protects the roof against leakage, since it has high wear and moisture-resistant characteristics. The same quality is important when painting metal elements in pools, bathrooms, showers. You can not use the paint only in the sauna, because it will not stand so high temperatures.

Oily

Oil paints are the least durable of all. They do not withstand temperature fluctuations and at negative indicators quickly lose all their properties. Over time, the paint cracks, wear out quickly. Therefore, they are used only when carrying out internal repair and finishing works, and then in places not subject to additional loads.For example, radiators or pipes can not be painted with such paint, although it refers to waterproof.

Removing the cover is incredibly difficult. As a rule, its removal is carried out only with the help of various chemicals intended for this purpose.

Acrylic

Acrylic paint is a two-component and multi-component, if the composition to add water or other plasticizers. Paints are resistant to moisture, UV radiation, the effects of climatic factors. Acrylic versions are used both outside and indoors. Guaranteed service life of coatings is 8 years. It is during this time that the metal under the acrylic material is not covered with rust. After this period, the coating can be renewed, and the protective properties will remain.

Alkyd

Such options are most often chosen for outdoor use. The covering turns out equal, with beautiful gloss. One of the most popular solutions is silver paint, which well protects the metal from external influences, while maintaining its unprocessed appearance due to a metallic coating. The only negative is that the paint is extremely toxic.

To carry out all the work properly, you will need to carefully protect the surface of the skin and respiratory tract.

Anti-corrosion

These include compounds that not only protect metal structures from aggressive environmental influences, but also are able to stop or prevent the processes of rust formation and development. There are both single-phase and multiphase compounds (for example, primer, transducer and paint in one). If it is necessary to fight corrosion with high quality, then it is anticorrosive coatings that are chosen.

Ground coat

Primer paint for metal is used to improve adhesion and material preparation for decorative painting. It not only masks and levels the surface, but also hides traces of rust, small cracks. As a rule, priming solutions are white. As a basis, synthetic resins are used, which will improve the adhesive properties. Additionally, priming paint increases moisture resistance, protecting the metal from further destruction.

Enamel primer

Means unite in themselves two types of a covering: grounding and decorative.If you choose the right enamel, then in the future when painting you can do the minimum preparatory work. Do not even have to scrape off the old paint with metal. As a rule, primer enamels are quick-drying anti-corrosion coatings. They dry for a couple of hours without losing the brightness of the color. The resulting coating has a high hiding power. If necessary, the composition can be slightly diluted by adding xylene or solvent to it. Soil enamels are universal options.

Powder

One of the advantages of using powder mixtures is practically waste-free application, while liquid paints remain in the can or spray gun, albeit in small quantities. Powder paints can produce interesting effects. For example, they can be used to form a patina on any metal part. So, the use of paint-powders opens up a wide field for design experiments.

Depending on which film-forming resins underlie the mixture, there are two categories of powder paints:

- Thermoplastic. One of the main positive features is how exactly the coatings are repaired.If the paint is slightly cracked or warped (which is almost impossible), it is enough to melt the place with the damaged coating a little. Among other things, paints are resistant to almost everything: salts, moisture, sand, therefore sea vessels and boats often cover with thermoplastic compounds.

In addition, this species is one of the few that can come in contact with drinking water without poisoning it.

The following types of thermoplastic mixtures are distinguished:

- polyvinyl chloride (PVC);

- polyamide;

- polyolefin, which, in turn, are polyethylene and polypropylene.

- Thermoreactive. Most often with the help of thermosetting powder mixtures cover the car bodies. This is due to the fact that the material is not flammable, does not melt, is resistant to solvents, and also protects the metal from corrosion. Depending on which substance acts as a base, the coating may have certain decorative characteristics.

Thermosetting powder mixtures have five varieties:

- Epoxy enamels are still common in everyday life. Because of the extreme toxicity, they can not be used indoors, and even working outdoors should have to apply increased safety measures.However, the "epoxy" forms a transparent coating on the metal surface, as it varnishes it. The material does not differ in a high degree of adhesion, as a result of which it is replaced by all sorts of modern analogues.

- Epoxy-polyester coatings do not turn yellow with time, so they are used on surfaces exposed to UV radiation.

- Polyester powder paints have the best protective properties. They protect the metal from corrosion, mechanical effects, atmospheric phenomena, moisture. The coating is brilliant, smooth and glossy.

- Polyurethane powder blends can make the metal surface shiny, shimmering, as if silky. The effect is warm and soft material. Polyurethane options are often chosen precisely because of the decorative properties.

- Acrylate compositions have good resistance to temperature effects. In addition, these paints are alkali resistant. For a long time they do not lose color, do not lose their glossy shine. However, in the premises such options can not be used. They are suitable only for external work.

Design and colors

Metal paints are available in a large assortment of different colors. The leading place is occupied by coatings that imitate the color and texture of precious or other metals. Examples include copper paints, "under gold", "under bronze." The chrome coating is a leader because it fits well with various modern stylistics: modern, hi-tech, loft.

Not lagging behind and mirror paint, giving an interesting and unusual effect.

Among other things, it has an additional advantage: if you use it indoors, you can visually increase the space. Due to the fact that the mirror surface of the metal elements will reflect the environment, the room will seem larger.

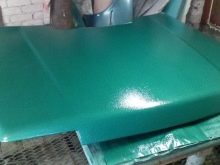

There are interesting solutions made in basic colors: gray, black, white, dark blue, bottle green, bronze or copper. Such parts or objects will look good both outdoors and indoors. Quite another thing - bright options. If red can be considered a universal color, then pink, blue or green would be appropriate to look only inside the room.

In some cases, there is a need to stylize a metal for some other coating, for example, a ceramic tile. Paint will help here. Only the method of its application is different: you need to be able to reliably simulate divorces. The same applies to the stylization of natural stone, and the design of antique. In case of artificial aging of the surface, patination is often resorted to using patina powder in addition to the basic paint of the color of some metal (usually copper or bronze).

Metal paints are divided into glossy, semi-gloss and hammer. Due to the substances contained in such formulations (most commonly resins), the coating cannot be completely matte.

Glossy

Smooth glossy coatings are very popular largely due to the fact that they fit into any interior and exterior. If you make a glossy metal part of a bright color, then the look will fall on it, and it will become accent. As a rule, glossy shiny paints are available in bold bright colors.

Among the most popular colors are the following:

- magnolia;

- Navy blue;

- yellow;

- green leaf;

- silver;

- white;

- blue;

- Gray;

- brown;

- light gray;

- golden;

- green;

- brick red;

- the black;

- light brown;

- red;

- cherry.

Among other things, the durability belongs to the advantages of glossy coatings. Glossy paints are more resistant to abrasion, so they are more suitable for outdoor work than matte. It is also better to choose a glossy finish for those places that you plan to regularly wash: for example, metal sinks, heating radiators in the kitchen.

Such good performance is due to the fact that after the evaporation of moisture from the paint, the coating turns into a film that protects the surface.

Another advantage of using gloss paint is the ease of care for such a coating. All you need to do is wipe with a rag to remove marks. Depending on the degree of resistance of the paint to water and friction of a glossy surface, treatment with a specific solution may be necessary, but dust and dirt do not adhere to the gloss, like matte coatings, and they are not so noticeable on gloss.

Semi-matt

Such paints are often called satin because of their gentle unobtrusive gloss.In appearance, semi-matt paint is not too different. It has a subtle gloss, not as pronounced as that of glossy coatings. Such options are more often used indoors. They paint the radiators, pipes and other infrastructure of the house.

In the event that chipping occurs on the coating, it will not be noticeable as if gloss paint had been chipped off. In addition, the semi-matt coating is easy to update: here the joints will not be so noticeable when the surface is fragmentary stained. It is also relatively easy to clean paint, as it doesn’t differ much from glossy in terms of its technical characteristics, it only shines less.

Such paints are more often chosen for decoration of various public institutions: schools, institutes or other educational institutions, hospitals, office and shopping centers, kindergartens, because they are non-staining, and metal surfaces covered with satin paints can be washed without fear that the paint will react badly to moisture, fade, the view will deteriorate in some other way.

If you want a metal surface to stay elegant,but not ready to make it accent, the best choice would be to use a semi-matt version with an unobtrusive sheen.

Hammer

The paint owes its name to the specific surface that forms after dyeing. It is similar to the surface of the hammer: the same non-uniform and slightly rough. To achieve this effect, different substances are added to the composition: aluminum powder, fine glass and others.

The list of colors of the hammer variety is quite large:

- brown;

- light green;

- blue

- golden;

- copper;

- red;

- dark blue;

- gray

- black;

- dark green;

- silver gray.

Due to the fact that the hammer paint has a high resistance to all kinds of influences, such as humidity, temperature and vibration, it is used in production.

During outdoor work, it also proved to be good, protecting metal surfaces from all sorts of negative influences.

Another advantage is that the hammer variety can be applied directly to the surface damaged by corrosion, and it is not necessary to pre-prepare the base: the paint will lie flat and firm.As a result, an airtight film is formed, which will prevent the further development of corrosive processes. With the help of hammer inks, metal entrance doors are most often drawn up, since, among other things, such compositions are also anti-vandal: they are hard to damage by mechanical effects.

What to consider when choosing?

So, going to the choice of a suitable paint for metal, do not forget to evaluate some significant criteria.

- Surface type Of great importance is exactly which surface will be painted, and where it will be located. For example, not all types of paints are suitable for painting a fence made of galvanized metal, otherwise there is a great risk that the paint will not grasp with the surface and will soon peel off.

- Consumption. This parameter is directly correlated with the planning costs of repair and finishing works. So, when working with rusty metal bases will have to spend a lot more paint. In addition, some of the paints must be put in two layers, which also significantly affects the amount of spent composition.

- Frost resistance. If an element is being painted that will be located outside or in an unheated room, then it must be ensured that in winter, when the temperature drops below zero, the paint will not crack and the metal structure will not have to be repainted in the spring.

- Cost This factor is also directly related to the planning of repair costs. It should be borne in mind that the most common are the cheapest paints without any additional protective properties, and the most expensive are rust paints or anti-corrosion coatings.

- Manufacturer. It is important to pay attention to the availability of certificates, as well as to whether the paint is made in accordance with the standards of GOST. As practice shows, the manufacturers who make the best paint are well-known; do not risk buying products of a brand that nobody has heard of.

To learn how to paint the metal, see the next video.