Sealant for laminate: how to choose?

Laminate is one of the most popular types of flooring. However, this material has its drawbacks, expressed in low moisture resistance and the likelihood of squeaking, and to remove them during installation, you can use a special compound - sealant.

Why do you need?

As a rule, low cost options for laminate do not have good water repellency characteristics. During long-term operation of the floor covering at the joints, voids and cracks may form, which leads to the appearance of a squeak. To improve the performance of the laminate and to avoid many of the problems associated with flooring, it is recommended to use a special sealant during installation.

When laying laminate lamella fasten with each other using special locks. The lower layers and locks of the floor covering are most sensitive to moisture and mechanical stress. The top decorative layer of a floor covering cannot provide their full protection against moisture.

Water can easily seep into the inner layers, leading to deformation of the floor covering.

Sealant for laminate protects the lock joints from external influences, which allows to increase the life of the floor covering. It can be used not only in rooms with a high level of humidity, but also in excessively dry rooms to protect the floor surface from drying out.

Sealant for laminate is applicable for the following purposes:

- protection of seams against the passage of moisture;

- prevent the formation of cracks in the joints;

- with the help of acrylic sealant, you can seal the chip on the laminate;

- providing the possibility of carrying out wet cleanings laminate coating.

Only high-quality sealant can cope well with all tasks.

Such material should have the following characteristics:

- environmental friendliness and safety for human health;

- high level of protection against moisture penetration into the gaps between the laminate panels;

- the floor covering can be dismantled and used for secondary installation;

- ease of application;

- wide range of operating temperatures;

- high drying speed;

- does not leave pollution on the laminate;

- does not stick laminate panels;

- increases the level of noise insulation.

Specifications

The specifications of the laminate sealant will vary depending on the composition of the mixture.

When buying a gel should pay attention to the following indicators:

- The color of the material. Both colorless transparent and pigmented gels are available.

- Drying speed. The average drying time for putty is between fifteen and thirty minutes. It is recommended to operate the treated coating twenty-four hours after applying the sealant.

- Mixture consumption per linear meter.

- Shelf life of sealant.

- Presence or absence of such properties as moisture resistance and frost resistance.

Composition

The composition of the sealant will depend on the specific type and manufacturer of the material.

In most mixtures, the following components are present:

- Antiseptic additives. Able to prevent the spread of mold and mildew.

- Quartz flour or chalk.

- Pigments.

- Organic Extenders. These components are used to reduce the viscosity of the sealing compound.

The composition of the sealant should not be toxic substances - it is recommended to make a choice only in favor of environmentally friendly materials. Also, the quality composition for laminate should have good elasticity.

Kinds

Depending on the composition of the sealant will vary the properties and characteristics of the mixture.

The composition of binders for laminate is divided into two main types:

- silicone based;

- based on acrylic.

The silicone version is characterized by elasticity, good adhesion and durability. Silicone-based putties are completely eco-friendly. The mixture is easy to apply and leaves no residue on the surface.

It is worth noting that silicone options can not be painted in a particular color. You can purchase a transparent material or a mixture of the desired shade.

Acrylic sealant for laminate can be used to eliminate minor defects (chips, cracks) of the floor covering.The structure of the material based on acrylic less solid and more elastic than the silicone version. Gels based on them are rarely colorless.

To choose the right color gel composition for flooring, it is recommended to have a laminate sample with you.

Brands

Despite a wide range of laminate sealing compounds, consumers often prefer proven brands. Below are the most popular brands.

Click guard

Click Guard is a German-made water-repellent sealant. Protects the inner surface of the laminate and locks from moisture penetration. A mixture of Click Guard can be used in the kitchen, loggia, bathroom and hallway.

The sealing compound has no adhesive properties and does not interfere with the disassembly of the laminate. The material is produced in a tube of 130 grams. Tube consumption can range from 8 to 10 m2. Drying time can vary from 15 to 25 minutes.

Buyers will highlight only one drawback of this product - the high cost.

Among the advantages noted:

- Ease of application. The mixture has a rather thick texture and does not flow.

- Slight smell.You can carry out work in an unventilated area.

- Short drying time.

- After drying, the sealant forms a thin transparent film on the surface. Excess on the front side of the laminate is easily removed.

- High quality.

Click Protect

The Click Protect sealing gel of the French-German concern Bostik is used when installing laminate coatings with locking joints. The sealant securely fastens the strips and protects the coating from moisture penetration. The material is made on the basis of polyurethane. When dried, forms a transparent film on the surface that is easy to remove.

Available in a 125 ml tube. One tube of the mixture is enough to handle ten square meters of surface. The sealant dries on the surface within 30 minutes.

Product Click Protect has both positive and negative reviews.

Consumers distinguish the following benefits of the product:

- good moisture protection;

- ease of application;

- short drying time.

In the process of use, consumers have identified the following disadvantages:

- Strong smell.

- It has adhesive properties. Does not allow dismantling laminate.

- Burns the substrate.

- Large mix consumption.

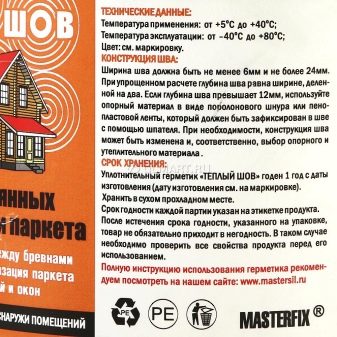

Masterfix

Russian Masterfix sealing mix is universal for wood processing, parquet, laminate and MDF. It performs the functions of a sealant and has adhesive properties; therefore, the laminate treated with such a composition is not subject to further use after dismantling.

Glue is available in a wide range of natural wood shades. Standard discharged volume is 290 ml. The mixture has a high drying rate. Work on the application of sealant should be carried out no more than 15 minutes.

Protect Click

Sealant Russian-made Protect Click is designed to protect the joints laminate. Sealing mixture protects the surface from moisture penetration, and also improves the wear resistance of the coating. This material can be used for treating the floor in wet rooms or in halls with high traffic.

In addition to moisture resistance, Protect Click sealant has frost-resistant properties. Available as a colorless gel in a 125 ml tube.

One tube of sealing compound is designed to handle ten square meters of coverage.

Reviews of Protect Click gel are extremely positive.

Buyers highlight the following material benefits:

- high quality;

- excellent protection of joints from moisture penetration;

- promotes good fixation of the floor covering;

- high drying speed;

- does not prevent further use of the laminate after dismantling.

Which is better to choose?

In the modern building materials market there is a large range of sealants for laminate.

When choosing a suitable material, you should pay attention to the following factors:

- The purpose of the application. The material can be used for sealing joints during installation, grouting of joints after installation, restoration of old flooring.

- The quality of the sealing mixture. Not always the high price or a well-known brand indicates good quality of the material. Before you buy better read reviews on popular products.

- The composition of the sealant. It is necessary to pay attention to the presence of harmful toxic components. The purchased product should not be hazardous to health.

- Drying time

- Application instructions. The method of applying sealant is always indicated by the manufacturer on the packaging.From some features of the use of the material depends on how easy it will be to lubricate the joints with such composition.

- Color blend. To eliminate small defects on the surface of the laminate, you can use color acrylic sealant.

- Consumption. Before carrying out repairs, it is necessary to calculate the required amount of sealant. The consumption rate of the mixture indicated by the manufacturer on the packaging.

How to apply?

Processing joints laminate sealant is carried out when installing a new coating or to strengthen the old. The joint between the tile and the laminate without a nut can be sealed with silicone sealant.

In the case of laminate repair or disassembly, the old sealant layers must be carefully cleaned for future use. Remove the sealing mixture using a solvent or a metal spatula.

After the cleaning procedure, the laminate locks must be wiped with a soft cloth.

Work on the formation of the joint is required to carry out with great care. Sealant for laminate and floorboard should form a bond with the sides of the joint without penetrating to the back surface.The back surface of the laminated panels can be protected with a special gasket or polyethylene.

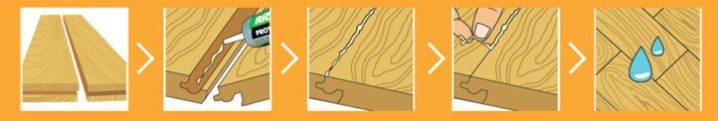

The process of applying a sealing agent is as follows:

- A tube with a sealing substance is inserted into the seam at an angle of 45 degrees.

- Pressing on the tube, you need to evenly apply the gel to the surface. To facilitate this process, it is recommended to use a special sealant gun.

- Care must be taken to ensure that there are no untreated areas in the joints.

- If the sealing mixture has gone beyond the seam, then it must be removed from the surface with a spatula moistened with water.

- The procedure for applying a sealant and connecting strips should be carried out fairly quickly. Fifteen minutes after application, most sealants begin to harden.

- Excess sealant from the surface can be removed with a damp cloth or special tools.

For more information on how to choose a sealant for laminate, see the following video.