Coatings "Russian laminate" in a modern interior

Recently, there has been a tendency to increase the demand for finishing materials of Russian manufacturers. This also applies to laminated coatings. In today's economic situation, for a consumer, Russian products are more profitable in terms of price than products of foreign companies. And the quality of such coverage is quite decent. For example, the coating from the company "Russian laminate" has proven itself well.

About company

“Russian laminate” is a company that has been on the market for more than ten years, although it has a history of its production since 1993, when the production of chipboard using the equipment of the company was started on the basis of a small workshop. Bison in Sergiev Posad. In 1998, the first chipboard laminating line was launched.

Today, the company "Russian laminate" - these are two modern plants located in Moscow and Smolensk regions, own logging and a wide network of official representative offices throughout the country. The range of products is constantly growing due to the smoothness of the production process and careful monitoring of product quality at all stages of production.

In addition to the main products, the company also produces related products, such as DVPO, furniture accessories, edging material, aluminum profiles for cabinets and facades.

The high quality of the products of this company and the positive feedback from consumers is the result of a long and painstaking work of a team of professionals. Competitiveness and high demand for the products of "Russian laminate" is ensured by:

- Highly qualified employees;

- Compliance of technical equipment of plants with modern requirements;

- The use of modern lamination lines Wemhoner;

- The presence of in-house production of resins, thereby minimizing problems with the delivery of this component in the cold season;

- The application of a strict quality control system of the finished product. In the production process, continuous control of mass, thickness, density of particle board is carried out. And in special laboratories, the level of impregnation is monitored, as well as the characteristics of the coating films. Each plate is also subject to visual inspection. The product quality indicators are checked both during the production process and after the application of the laminated coating on the chipboard;

- Environmentally friendly flooring. The plates of this brand contain formaldehyde in the amount below the established norms.

All products of the company have certificates of compliance with current Russian safety standards.

Review of the production of the company "Russian laminate", see the following video.

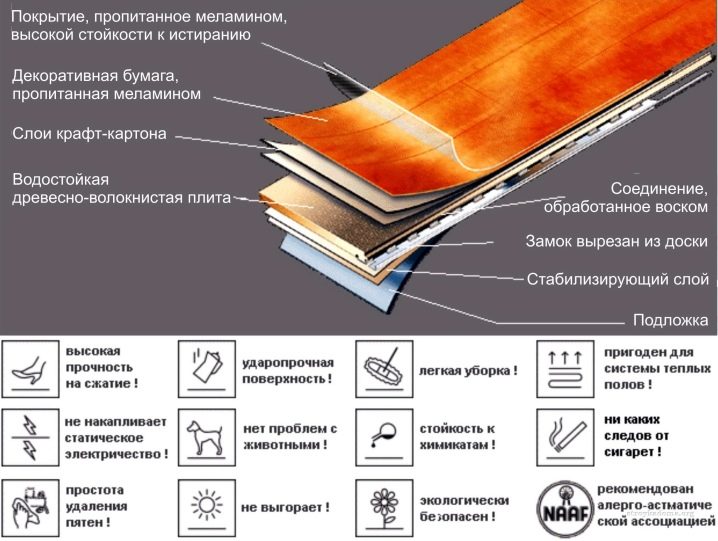

Materials and specifications

A chipboard board consisting of three layers with a fine structure is used as the basis for the manufacture of the laminated coating. Its main advantages are durability, environmental friendliness, abundance of color options, convenience and ease of processing. The raw material for the manufacture of DS-plates is large wood chips, chips, sawdust,in which, after grinding, thermosetting synthetic resin is added. Wood shavings are taken from wood processing hardwood and softwood.

After sorting the chips and cleaning it from impurities, it is dried, after which the resin is applied to it. The tar shavings are formed into a carpet, which is then divided into bags that are hot pressed. The pressed plates are cut to the required format. The plates prepared in this way are subjected to grinding. After that, the DS-slab is ready for further lining with laminated coatings. The film is applied on a chipboard under a press at elevated temperatures.

Each stage of production of chipboard is carefully controlled. The control process and the process of harvesting chips, and the final product. Wood chips are checked for geometry, moisture, fractionality. Resin chips used for bonding are checked for gelatinization and viscosity. To check the quality of the finished panels, make a selection eight samples from different places of the party. Using a press panel, the panels are checked for bending and determine the degree of warping.Also determine the swelling of the panels when exposed to steam and water, resistance to various kinds of mechanical stress.

Mandatory type of control is check on the degree of formaldehyde content. For this, a chipboard sample is placed in a chamber and after some time an air sample is taken from the chamber. The result obtained is compared with the standards. The Russian Laminate chipboard has an emission index of 4-6 mg per 100 g, while the highest emission class has a value of 8 mg per 100 g. Such material can be used in the production of even children's furniture.

Over the years, the company has determined for itself the most optimal properties of laminated coatings that satisfy consumers.

Physical and mechanical characteristics:

- Flexural strength - from 8.5 to 11 MPa for coatings from 38 to 10 mm thick, respectively;

- Tensile strength - from 0.2 to 0.4 MPa for coatings from 38 to 10 mm thick, respectively;

- Resistance at separation of the laminated coating - 0.8 MPa;

- Warp - no more than 1.2 mm.

Appearance:

- Dents - no more than 1-3 per square meter with a depth of no more than 0.2-0.4 mm and no larger than 5 mm;

- Inclusions - no more than 2 pieces (for grade 2 of coverage, for grade 1 they are unacceptable) with dimensions not exceeding 20 mm;

- Pore silverness is no more than 5% (for grade 2, for grade 1 it is not allowed);

- The presence of spots - no more than one with a size of no more than 30 mm (for grade 2, for grade 1 - not allowed);

- The presence of scratches - no more than 1 size of no more than 200 mm (for class 2, for class 1 - is not allowed);

- Brightness - no more than 1% of the surface (for class 2, for class 1 - not allowed);

- Not printed and skewed pattern - not allowed;

- Manifestations of particleboard waviness - insignificant (for class 2, for class 1 - not allowed);

- The presence of inclusions of large chips - no more than 3 pieces per square meter with dimensions not exceeding 15 mm (for class 2, for class 1 - not allowed).

In addition, the finished product must be resistant to staining, high air temperature and heat.

Dimensions

The company "Russian laminate" produces sheets of laminated DS-coating of standard sizes 2440x1830mm and 2750x1830mm. The thickness of the coating can vary from 10 mm to 38 mm. By the individual order at a factory plates of any sizes can be made.

Types of decor

The collection of color-textured solutions of chipboards is represented by 70 decors, which are divided into three groups. Their main properties are originality and versatility. Most of the collection is woody drawings imitating oak, elm, pine, walnut, larch, apple, maple, cherry. In addition to traditional wood structures, there are more original decors in the collection. For example, Arriva Oak or Antique Oak, made with the effect of an aged board, Arabesque - repeats the bleached board, Pine Winter - reminds worn white painted board.

Also in the collection are even color solutions. To give the panels of a particular color, special paper coatings are used with the appropriate design from leading European manufacturers: Bausch Decor, Schattdecor, Lamigraf. The manufacturer offers various options for the embossed laminated coating. This is a smooth embossing, and shagreen, and veneer, and wood pores, and textiles, and lamella.

Color solutions

All color layout is presented in the catalog of products "Russian laminate." Here everyone will find an option to their liking. The catalog consists of high-quality photos of all variants of coatings, the format of which allows them to be viewed in great detail.There are textures available for download in order to render them in design projects. The range presented in the collection of colors is wide.

Light colors begin with a simple white color, which gradually turns into beige, pistachio, Mint, White Birch, Maple, various options of light oak (Chamonix Oak, Milky Oak, Wenge Oak). Among the light shades of interest is Slate decor, whose image structure resembles a rocky pattern.

Medium hues are represented by decors of various shades. This includes all the bright colors of decors (Sky Blue, Blue, Pink, Green, Yellow, Red. Lavender), as well as woody shades (Beech Bavaria, Oxford Cherry, Ash Schimo, Crab Locarno, Safari Oak, Moringa, Transylvania, Provence Oak other).

Among the dark shades Anthracite, Marsala, Eucalyptus Mystery, Oak Chateau, Oak Tortona, Mahogany look especially interesting.

Design examples

Furniture made of laminated particle board in Chamonix Oak color of cocoa hues is very useful for creating an interior office space and helps to set up employees in a working mood. The façades of the living room furniture in Ash Wood color make the interior in bright turquoise-red tones closer to nature, and the atmosphere in the room is warmer and more comfortable.

Oak Country in the interior of the children's bedroom creates a calm and serene mood of the child. The chipboard in the Transylvania color, from which the ladies' table is made, takes us back 100-200 years ago, despite the modernity of the rest of the details of the room design.

The hall in the color of Ebony Dark saturates the room with warmth and makes its space more dynamic due to the presence of a brightly pronounced vertical wood pattern. The use of pink tones in the decoration of bathroom furniture makes this room more vivid and unusual. A kitchen with facades in white and pistachio tones sets a pleasant spring-summer mood to its inhabitants and increases the appetite.