Welded fences: the pros and cons

Welded metal fence is one of the most popular types of structures. Welded fencing has not only an attractive appearance, but also has high strength. Such fences are often installed on the household plots, as well as in urban production areas.

Special features

The welded protecting designs from metal are practical in use, differ in the high durability. Such a hedge can not only harmoniously fit into any exterior of the site, but also provide reliable protection against burglary and penetration.

Welded fences usually consist of the following elements:

- steel bar;

- galvanized shaped tube;

- metal construction mesh.

Despite the diversity of types, almost all welded enclosing structures have a number of common parameters.

You should consider the main ones:

- Manufacturers of welded structures manufacture sections in advance in the workshop.When installing the fence on the site, the fence is assembled as a normal "designer", which allows for installation in a short time.

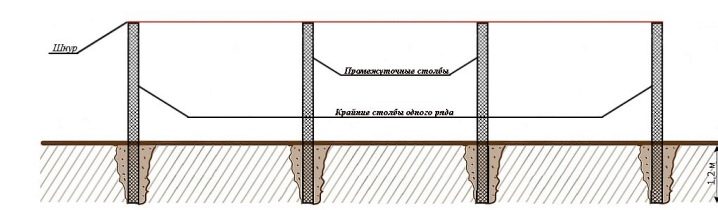

- The frame, which performs the functions of the clamp, are metal pillars.

- Frame supports may have different parameters depending on the characteristics of the landscape and installation site.

- The supporting posts are driven to a depth of at least 90 cm.

- The distance between the sections should not exceed 2.5 m.

Welded fences have their own distinctive features in comparison with other types of enclosing structures.

Some advantages should be noted:

- Large variety of species. You can choose a suitable design for any budget and for any exterior. In addition, such fences can be made independently according to your own designs, as well as use the services of craftsmen.

- Welded enclosing structures of all kinds of metal have a long service life. Qualitatively made fence can serve for fifty years.

- Installation of a welded fence is not particularly difficult.

- The cost of such structures, as a rule, is low.The exception is complicated to manufacture models with a variety of decorative elements.

- Metal welded fences are fireproof.

- Welded fences will not cast a shadow, prevent the penetration of air and direct sunlight on the garden plot. Such qualities allow creating favorable conditions for plant growth.

- Resistance to environmental influences.

In addition to the advantages, welded fences have their drawbacks.

The following disadvantages of such structures can be distinguished:

- The complexity of the paint work. High-quality painting of the welded hedge is a rather laborious process. The best option for coating will be sprayed paintwork material.

- These fences do not cover the space. For owners of private plots, this option of a fence is not always convenient, since any passer-by can freely observe the territory enclosed by a fence. In addition, this design does not protect against wind and dust.

- Welded fences are made of metal, so in the warm season the structure can be very hot under the influence of direct sunlight.Touching such fences in hot weather should be with extreme caution.

- Not all types of welded fences can provide good protection against intruders entering the fenced area.

Despite a number of drawbacks, welded fences are in great demand.

Such structures are most often installed on the following objects:

- playgrounds;

- industrial enterprises;

- cottages;

- private houses;

- land;

- parking lots;

- administrative buildings;

- city parks.

Types: advantages and disadvantages

There are many types of welded fences, each of which has its own advantages and disadvantages. Fencing structures differ in appearance and installation method.

From reinforcement or profiled pipes

The reinforcement design is the simplest and most budget type of welded fence. The manufacture and installation of such a fence does not take much time, which is a clear advantage of the fence. The disadvantages include a simple and aesthetically unattractive appearance. The reinforcement fence is most often installed as a temporary fence.

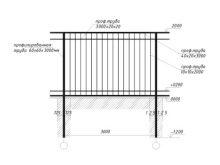

The design of the profiled pipes has a concise appearance. It is often used to enclose administrative buildings and public areas.

The advantages of the fence of profiled pipes include:

- ease of installation;

- long service life;

- good overview of the fenced area;

- attractive appearance;

- possibility of installation on relief surfaces.

It should be noted that such structures do not protect the area from noise and dust. In addition, profile fences do not provide an adequate level of protection against intruders entering the fenced territory.

Sectional

Welded construction of the sections are an improved version of the fence from the reinforcement or shaped pipes. In this case, fittings or profile tubes are placed in a prefabricated frame. Sectional designs have an attractive appearance, are easy to install.

From the grid

Welded fencing mesh is made in two versions: with frame and without. Grid fences are easy to install and low cost. Wire structures are used to enclose residential buildings,and industrial facilities. The steel wire fence copes well with protection against the entry of animals into the territory. Also similar designs can be used as a lattice for climbers. A variety of mesh welded fencing is a model of 3D panels with a polymer coating. The sectional 3D hedge from a welded grid differs in the high durability, and also has original appearance.

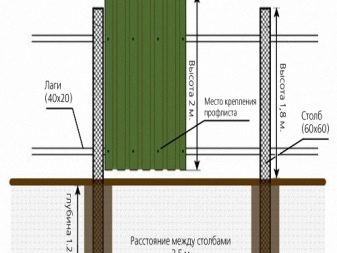

From metal profile

Metal structures are the most difficult to manufacture. The fence made of corrugated board on screw piles does not belong to the budget options, but has an attractive appearance, and also has good resistance to mechanical stress. Metal fence sections are opaque, which allows you to hide the fenced area from prying eyes. This advantage is a disadvantage for some owners, as an opaque fence will cast a shadow on the plants, preventing the penetration of sunlight on the garden.

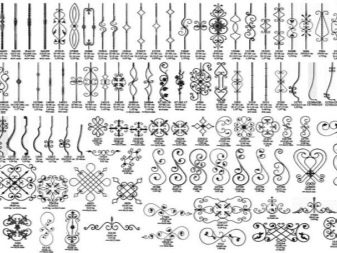

Forged

Forged welded fences are different original appearance. Forged designs can be made according to author's sketches.

The advantages of such a fence include:

- quick assembly of the structure;

- esthetically attractive appearance;

- durability;

- ease of installation.

The main disadvantages of forged fences are the high cost of the product, as well as the fact that they do not protect the surface to be protected from inquisitive views.

With decorative inserts

Fences with decorative inserts are the most beautiful type of welded fences, but the cost of such structures will be quite high. Decorative elements can be made independently in order to mount them on the already existing welded fencing of another type. Independent decoration of the fence requires certain skills. It will take a lot of time, but will save money.

Installation Tips

Before proceeding with the installation of a welded structure, it is necessary to perform a series of preparatory work. First of all, it is necessary to determine the location of the structure, to mark the territory, to install support columns. The distance between the pillars should not exceed 2.5 m.

The following materials can be used as a support:

- metal pipes with a diameter of more than 5 cm;

- columns from a profile pipe with a diagonal of more than 2 cm;

- other designs of factory sizes.

After marking the location of the supporting pillars on the site, it is necessary to prepare a pit for each of them. The holes are made with a drill. The diameter of the recesses should be slightly larger than the diameter of the pillars. The depth of the pit is calculated based on the future height of the fence. The standard construction height is 1.5-2.5 m.

In most cases, it is enough to make holes in the ground at a depth of 60 cm. If installation of supports is planned, then the pillars must be driven into the ground to a depth of another 30 cm. After this, the pits are filled with concrete. The next step is the preparation and installation of floors. The order of further actions depends entirely on the type of welded structure that will be installed on the site.

Before installing fencing of reinforcement or shaped pipes, you need to decide on the material. Structures made of reinforcement do not provide good protection of the territory; therefore, they are most often used as a temporary fence. For the fence it is better to take rods with a diameter of more than 1 cmsince such a construction will be more reliable.

Installation of overlaps is carried out in the following order:

- measurement is done;

- twigs are cut;

- carried out welding work.

Pipe size will depend on the installation method. The easiest way to install the structure is to arrange the rods perpendicular to the support pillars, however, fences with parallel support rods will look most attractive. After the bars of the required size are cut, you can start welding the structure. This stage is not difficult if you have welding skills. When installing it is important to ensure that the welds are continuous.

The installation of a sectional fence is similar to the installation of a mesh fence.

The process consists of several stages:

- frame making;

- welding;

- installation design.

For the assembly of the frame using the corners of the metal. The frame is made in the form of a rectangular structure. The height of the frame should be equal to the height of the fence. First, all four sides of the future frame construction with corners washed at 45 degrees are harvested. Then the sides need to be welded together.For the manufacture of overlapping sectional design, you can use a profiled pipe, mesh or reinforcement. The selected material is welded to the frame. The finished sections are attached and welded to the metal rods on the support posts.

Already installed welded fences can be decorated with forged decorative elements. This procedure is cheaper than buying a finished forged structure. You can both buy ready-made forged items, and order work from the master.

The following decorative elements are most popular:

- forged peaks of various designs and sizes;

- forged ornaments;

- figures of animals and plants;

- monograms and rings;

- plugs for pillars.

Installation instructions for the fence, see below.