Screw piles for the fence: the pros and cons

The technology of building fences with screw piles is very popular. It allows you to solve the problem of stability of the fence on floating and loose soils, as well as guarantees the reliability of the structure during seasonal fluctuations of the soil.

Special features

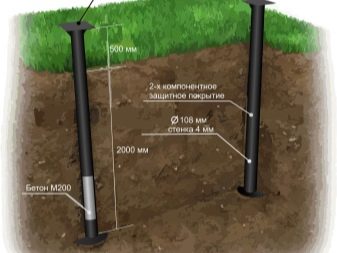

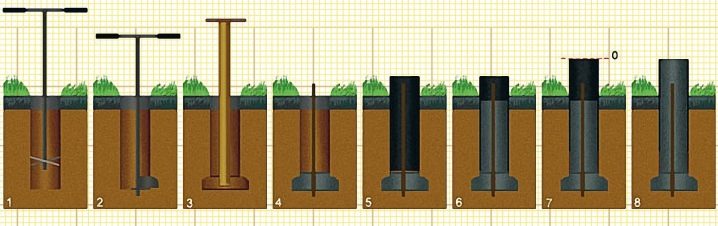

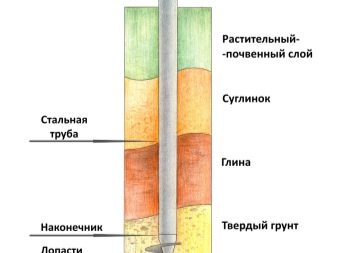

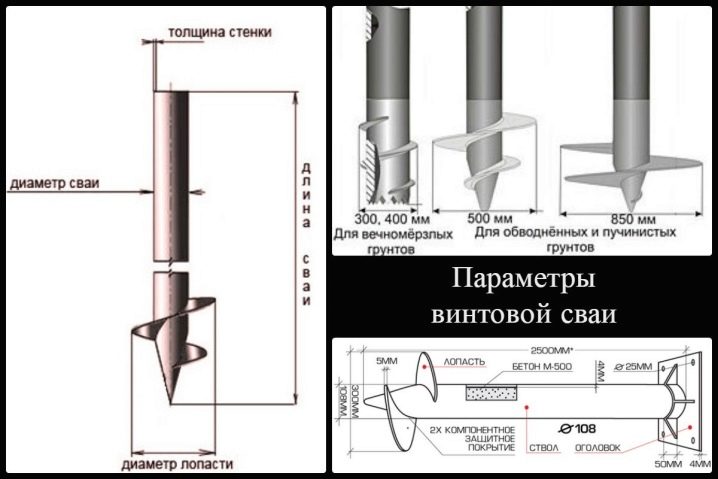

Screw piles are threaded hollow pipes equipped with a weld tip. For the construction of the fence on stony soils, combined models with additional blades are used. They provide uniform load on the metal pipe and increase the strength of the structure. On peat and sandy soils using piles with a closed tip, on all others - with an open. The pipes are produced with different diameters, the choice of which depends on the soil, the height of the barrier, the material to be filled, the presence of the gate and the entrance gate, the wind load and the level of soil freezing.

The most common are pipes with a diameter of 76 and 89 mm. They are intended for installation of a fence from a professional leaf, slate, a metal shtaketnik and ready welded sections. For a lightweight fence from the netting of a chain-link or wooden picket fence, piles with a diameter of 57 mm will be enough.

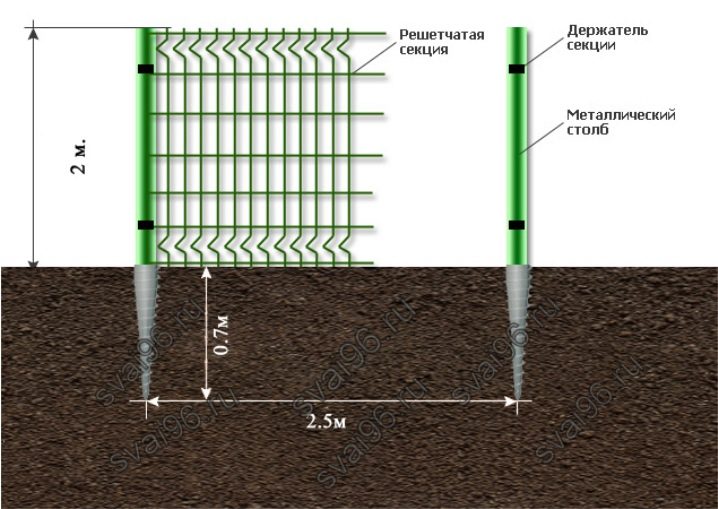

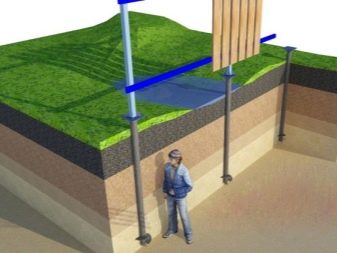

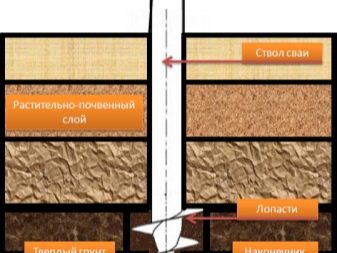

Screw piles are installed in the ground below the level of soil freezing. Installation is made with a certain step equal to the length of one section. On top of them are mounted pillars, between which is filled. As they are often used pipes of a smaller diameter, which are inserted into the pile cavity and securely fixed in it.

Benefits

Popularity and growing interest in screw pile technology due to the following advantages of these structures:

- Reliable fixation and high stability of the pillars are due to the presence of threads and blades with which the pipe is screwed into the ground without loosening it. A correctly installed pile can withstand a load of several tons and last up to 100 years.

- Quick and easy installation. Installation of screw piles does not require concrete or earthworks and can be done by hand, without the involvement of special equipment and professionals. Work can be carried out all year round, including at low temperatures.

Thanks to the simple dismantling, the piles can be reused. The time of screwing in one pipe by hand is 30 minutes. Full installation of all structures on the site takes from one to two days depending on the area and complexity of the relief.

- The possibility of using screw constructions on any type of soil, including marshy and heaving areas, as well as areas of permafrost and thermokarst. Installation of piles can be done on terrain with uneven terrain, including hard-to-reach places. At the same time, the soil layers are not mixed and not displaced, which happens, for example, when digging trenches and installing driving piles, but, on the contrary, compacted and stabilized. In places where there is a high level of groundwater occurrence, the use of metal piles is possible only after their preliminary anti-corrosion treatment.

- Durability. Screw piles can last from 50 to 100 years. The service life depends on the degree of load, the level of groundwater and the climatic conditions of their operation.

- The low cost of the material allows you to save up to 50% of funds, in contrast to the cost of a strip or columnar foundation.

The only restrictions on the use of screw piles are rock and stone-saturated soil.

Installation Features

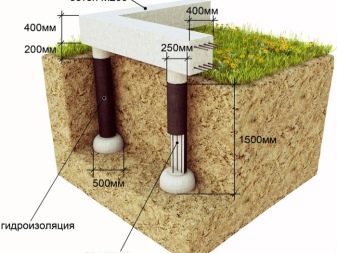

The first step is to determine the number of piles. To do this, measure the perimeter of the site, subtract the width of the gate and the gate from the resulting figure and divide by the calculated step. Usually its length is 2.5-3 meters and depends on the size of the filling material, the terrain relief and personal preferences of the owners. Then you need to make an exact markup indicating the screwing points of the piles, which should be slightly deepened. The depth of the screws must be at least one and a half meters.

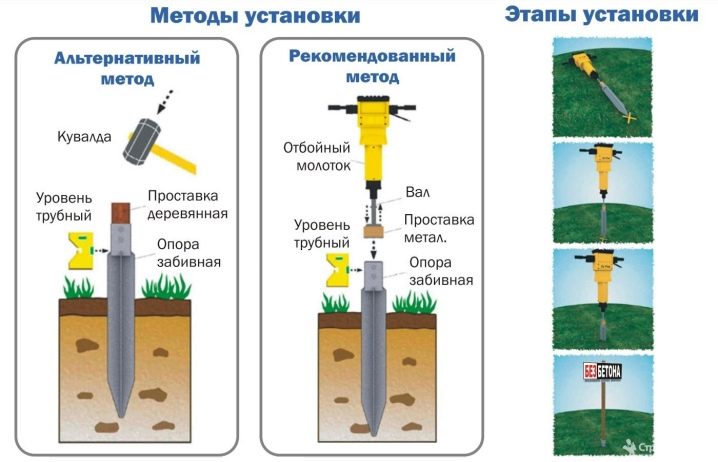

Then you can begin to screw the pipe. This should be done with the help of a special lever, in order to create it, a reinforcement with a diameter of 3 cm is inserted into the technological hole located at the upper end of the pipe. Sections of a pipe with a square cross section are put on both its ends, which will serve as a lever.

The minimum sleeve length must be at least two meters. In addition to self-made devices, you can use professional tools.The presence of a two-handed gate with a clamp will greatly simplify the work and help control the verticality of the screwing.

Installation should be carried out in three, where one person watches the verticality of the pile, and the second and third follow the twisting. It is very important to drive the pile precisely at right angles. The size of the deviation error should not exceed two centimeters, provided that no more than 50 cm of pipe remains on the surface. Control over the height and horizontal aboveground areas is carried out using a level or hydraulic level.

If necessary, the cavity of the sticking pipe should be poured with concrete, thereby preventing the ingress of moisture inside. On top of the metal, it is desirable to process a two-component primer mixture and anti-corrosion solution. Such an approach will significantly extend the life of the steel structures and maintain their original appearance for a long time.

The upper part of the pile, located above the ground, can play the role of a pillar. Therefore, when choosing the length of products should be summed up the screw-in depth and height of the support.

The next step is to tamp the space adjacent to the pipe, followed by cementing or installing a plastic plug.This will help prevent soil erosion near the base of the pillar and will provide higher structural stability.

Next, using special fasteners or welding, you can begin to install the guides. The final stage of installation is to secure the filling.

Tips for choosing

Before proceeding to the choice of piles, it is necessary to determine the diameter and length of the pipe, on which the bearing capacity of the structure directly depends. For installation of light barriers with wooden or plastic filling, it is enough to purchase pipes with a wall thickness of 2 mm and a diameter of 54 mm. When buying piles for the fence of corrugated is better to give preference to models with a diameter of at least 89 mm. And for the construction of arbors, terraces and greenhouses it is necessary to use powerful products with a wall thickness of 8 and a section of 108 mm. In this case, the pile foundation is subjected to strapping with the further erection of the building.

If it is not possible to conduct geological surveys of the soil and exclude the presence of a large number of stones and the presence of rock, then a trial should be carried out. To do this, you need to purchase one pile and screw it into the ground.The cost of the pipe will be from 800 to 1000 rubles, which is much cheaper than expensive geological surveys. Self-testing will help determine the depth of the upper groundwater and the bearing capacity of the reservoir at the level of the immersion screw. On the basis of the conducted testing, the desired height and design of the future fence, it is necessary to determine the desired pile length, pipe diameter and blade power.

Some models are already equipped with holes for fastening the guides, which greatly simplifies installation and reduces installation time. They are fastened with dowels or screws.

When filling the spans with a wire net, the fabric fasteners can be made with soft wire or metal clamps. To prevent sagging grid will help tight wire, placed in the top row.

Reviews

Screw piles for the fence are rapidly gaining popularity and have a lot of positive feedback. Consumers consider them as an excellent alternative to brick-based fences in cases where laying the strip footing is not possible. There is a maximum preservation of the terrain and no need to dig trenches.The process of screwing in the piles is estimated as the least time consuming and quick compared to other types of structures.

Attention is paid to substantial savings in cash and the possibility of saving on posts, the role of which is performed by the above-ground parts of screw piles. The advantages include the possibility of self-assembly without the use of additional consumables and the involvement of specialists. Dismantling and reuse of piles is also noted in the reviews.

Screw piles have a few minuses. Consumers note the need for geological surveys to determine the structure and quality of the soil. In the absence of the results of the examination requires independent testing of the soil by screwing in a prototype. The disadvantages include the inability to use piles on rocks and areas with a large number of large stones.

Fence options

Screw piles are widely used when installing fences and barriers on any type of soil. They successfully solve the problem of close occurrence of aquifers and permafrost during construction.Due to its versatility, easy installation and low cost, screw metal structures are becoming increasingly popular and in demand.

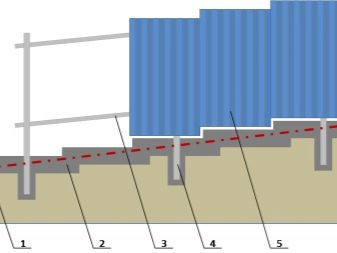

- Installation of the fence using screw piles on unstable soil.

- The use of the above-ground part of the piles as pillars allows significant savings.

- Screw supports perfectly level the elevation differences and allow you to install a barrier on the relief area.

- Thin screws without blades are a good solution for light picket fences.

- Short and thick piles for loose soils provide high stability.

- Powerful blades reliably fix the design in frozen and unstable soils.

What are the pros and cons of screw piles, see below.