Concrete fence posts: the pros and cons

The fence is a construction that performs several functions at once: from the limitation of the territory to its protection and beautiful design. It must be durable, reliable - and at the same time look aesthetic. All these qualities are largely dependent on the supports of the fence. One of the options for the frame for the fence - concrete pillars, which have many advantages. It is worth considering their pros and cons in more detail.

Main characteristics

Concrete is one of the most common and affordable building materials. It has a large number of positive qualities that are fully inherent in all products and structures made of such material. This also applies to concrete pillars for the fence. Such a fence can be installed around a residential building, public institution or on an industrial site.

Among the advantages of concrete foundations:

- moisture resistance;

- resistance to weathering and sunlight;

- ability to withstand various temperature effects (without compromising quality);

- rust resistance;

- universality - such bases can be installed on any soil, they are suitable for any landscape;

- durability and strength.

At the same time it is rather simple to establish support from concrete. During operation, they do not require special care.

If desired, the pillars can be further decorated. Inside you can install wiring. You can install lighting devices directly on the fence, giving the fence aesthetics and originality.

As for the disadvantages of concrete pillars, they most often include the need for a foundation and a considerable weight of concrete structures.

Types of supports

Pillars of concrete are different: both in form and in design. By their design features, they are divided into:

- Solid (monolithic). Have the greatest strength, able to withstand significant loads. Suitable for heavy enclosing structures.

- Stacked or prefabricated pillars, which are hollow decorative elements strung on a metal base and fastened with concrete, poured into the internal cavity.

Such supports are of great variety, and the cost of their installation is somewhat lower than that of monolithic structures. It should be borne in mind that the price may vary depending on the complexity of design. As for strength, for this parameter, the composites are, for obvious reasons, inferior to solid ones.

In a separate category, you can select small decorative columns with embossed or patterned decorations. Such supports are suitable for fences that are designed more for the design of the site than for protection.

The shape of the concrete support for the fence can be:

- round;

- square;

- triangular;

- multifaceted.

The most original solution is the combined structures in which various forms are combined. Whatever option you choose, the pillars will be equally strong and will reliably hold the entire structure of the fence.

The pillars are also distinguished by the method of attaching to them sections of the fence. Mounts can be:

- with longitudinal grooves;

- with mortgage bars of wood;

- with metal hinges.

Options for using mounts depend on the type of fence being installed. Groove joints are usually made on monolithic enclosing structures. Wooden bars are used in cases where the sections between the supports are made of wood.

As for metal fastenings, they are equally suitable for wrought iron fences, as well as for fences made of corrugated board or polycarbonate.

Compatibility

Due to its technical characteristics and versatility, concrete bases can be used to create fences from any materials. Most often they are combined with:

- concrete fences;

- structures from a grid chain-link;

- fencing of profiled metal sheets;

- forged bars.

In any case, they reliably hold the material, giving it additional stability and enhancing its ability to withstand wind and possible mechanical loads.

Decoration options

The usual concrete pillar looks dull and inconspicuous, therefore, special attention is paid to decorating the supports for fences. The main advantage in this case is thatthat the finish for the base of concrete can be used absolutely any.

Plaster - one of the most common options for decor. There are several types of plaster used for the design of fence posts:

- Lime-gypsum. The main feature of this material is 100% environmental friendliness. The composition of lime and gypsum is resistant to various mechanical effects and prevents the appearance of mold and fungus on the surface of the structure.

- Mosaic. The composition of this plaster contains the smallest stone particles, which gives the coating additional strength and resistance to damage.

- Mineral. It is made from a mixture of cement and lime.

- Decorative. Differs in the increased durability, long service life.

As a rule, plaster mortar is applied over the reinforcing mesh. She holds the mixture and does not allow it to slide down.

For concrete, epoxy, acrylic, rubber and polyurethane coloring compositions can be used. They will not only decorate the pillars, but also create an additional protective layer on their surface. It is important to remember that each paint has its own characteristics:

- For epoxy coating need a preliminary preparation of the concrete base. The paint itself is characterized by high color fastness, which later will be quite difficult to change.

- Acrylic paints distinguished by their environmental friendliness. They dry quickly, they can be applied in just 1 layer. This paint does not fade for a long time and resists well to high humidity.

- Rubber paints - relatively new compositions, resistant to moisture and easy to apply. They can be used even in wet weather and applied to dry pillars, but this should be done in several layers.

You can decorate the surface of the concrete pillar with the help of a polyurethane composition, which also has excellent characteristics. The only drawback of this paint is considered to be a long drying, which takes from 2 days to 2 weeks.

Lining brick or mosaic is popular. Mosaic can be different. When laying, you can use various techniques and lay out pictures. No less diverse decorative ornaments are created with the help of facing bricks, which can be smooth, "torn", angular or semi-circular.

Another popular type of finishing of intake supports is plastic panels, the installation of which does not take much time. A large number of colors and prints on them allows you to choose a design for every taste.

Features of the construction

Hollow concrete blocks for poles are represented on the modern construction market. Outwardly, they are stylized as natural stone, marble, wood and many other materials. In addition, it is possible to make supports for the fence on your own, observing a simple algorithm of actions.

When casting pillars of rectangular or square shape, pre-prepared formwork of plywood or planks, which must be carefully processed from the inside. If you plan to create supports round shape, then It is easiest to use a pipe of suitable diameter as a base for concrete.

At the same time, for columns of any shape, it is necessary to prepare a skeleton, which is a bundle of four reinforcement with a diameter of 10-12 mm, welded to each other with the help of transverse metal rods of smaller diameter. Thus reinforced concrete structures will receive additional strength.

To create a solution, experts recommend using cement brands M-300, M-500.

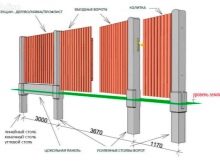

Installation of monolithic support pillars for the fence consists of several successive stages:

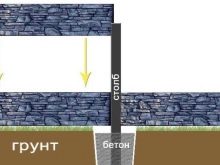

- Marking the territory and preparation of holes. All this is carried out taking into account what material will be used for intake sections. At the same time, the depth of the pits should not be less than 1 m. It is necessary to start marking from the corners of the future fence.

- The bottom of the hole for 10-15 cm is filled with rubble, after which the prepared metal base is placed there. Fastening the frame, it is poured concrete solution (throughout the diameter of the hole). Filling is carried out in small layers (20 cm each). Each layer at the same time sticks to prevent the accumulation of air.

- When the concrete "grasps", proceed to the formation of formwork. It should not come into contact with fittings. The inner walls of the formwork should be smooth, and the boards should be adjusted to each other so that the solution does not leak through them.

- Pouring mortar, after which the finished pillars are left in the formwork until the concrete is completely cured.

When carrying out all work, it is necessary to carefully ensure that the design is level, since after the mixture hardens, the situation cannot be rectified.In this case, even the slightest violation of geometry can lead to rapid destruction of the pillar and the entire fence.

In addition, the performance of the columns is largely dependent on adherence to technology. Particular attention should be paid to the composition of the concrete mix: it must be done strictly according to the instructions on the package.

As for the pre-fabricated pillars, during installation, their internal cavity should also be poured with concrete - in order to give the foundation additional stability and strength.

Installation is carried out according to the following algorithm:

- After digging the hole and filling it with rubble, the core is installed in the center, supported by spacers. A metal pipe is used as a core.

- The frame is concreted, after which structural elements are strung on the pipe.

- Each element of the pillar is filled with concrete mix. The following fragment can be laid only after the concrete “stuffing” of the previous one hardens well.

- When all parts of the pole are installed, a special cap is mounted on top, which will serve not only as an ornament, but also to protect the concrete from erosion.

To improve the quality and extend the service life of such support pillars, all their seams must be additionally treated with a hydrophobic solution. An important condition for durability and structural strength is considered to be mounting in dry weather. Precipitation and high humidity can "make adjustments" to the concrete mix and prevent proper solidification.

You will learn more about concrete pillars for the fence in the following video.