How to glue linoleum: methods and materials

Linoleum is a polymeric material that is used as a universal floor covering. In popularity, it competes even with laminate. It is distinguished by ease of use and mobility, it is not difficult to creep and, if necessary, can also be easily removed. A variety of colors and textures will satisfy all tastes and harmoniously fit into the interior and functionality of each room.

Based on the list of positive qualities, it is widely distributed among consumers, and this leads to a number of problems with regards to the correct technology of styling, bonding joints and other production nuances. A special procedure is the processing and fastening of the seams between individual sheets, which also raises many questions.

Coverage Features

Linoleum can easily be laid even by a person who is far from finishing work.Its surface is convenient and easy to wash, it is not afraid of water, the movement on it is soft, not causing noise. This is the best option for many residential and commercial enterprises.

The division of linoleum into types depends on the material of manufacture, wear resistance and structure.

Linoleum on a felt basis, which can be household and semi-commercial, is quite popular.

Its main features are:

- The multi-layered and soft structure holds its shape better and is practically not subject to deformation;

- He springs even on the concrete floor;

- It has a sound insulation property;

- Due to the impregnation of anti-flammable substances the possibility of ignition is minimal.

- Well retains heat and boasts a long service life.

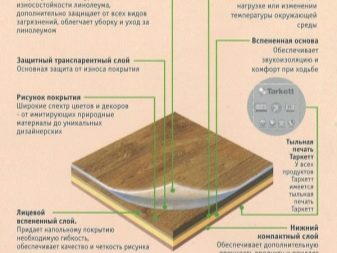

In the Russian market, it is presented in two versions, which in certain modifications can have from 5 to 7 layers:

- PVC - protects against physical and chemical exposure;

- The second layer of PVC is similar to the first layer of the function, there is not in all types of coating;

- Printed pattern coating;

- Foamed PVC - does not absorb moisture and prevents deformation during operation;

- Fiberglass - stabilizes among all the layers;

- Felt backing is the base;

- An additional layer of waterproofing that protects the felt from moisture.

Styling features:

- The floor must be flat and dry. The material itself is hard cut with a knife, this must be taken into account before starting work and choosing the right tool;

- For rooms with a high level of humidity, linoleum on a felt basis is still not suitable, it begins to mold and rot;

- It is desirable to have a monolithic coating of the entire area, it is extremely difficult to weld it and only the master should weld the seams;

- In places of a joint the additional water-repellent tape glues, it is impossible that water got to gaps. Skirting boards should fit very tightly.

Linoleum on a fabric or textile base is presented in two layers: the first is synthetic or natural felt and the second is PVC with decor.

It is used mainly in residential premises and has the following properties:

- Heat and sound insulation;

- Softness and elasticity;

- Does not require the help of experts when laying;

- Environmental friendliness and safety.

It can be laid on a flat surface or on an old floor if it lies without displacement.At the joints is required protection from water, the use of baseboards. Negative qualities include a relatively short service life and high cost.

Commercial linoleum - coating designed specifically for places with a large flow of people. It is wear-resistant and is used in schools, hospitals, offices, corridors, cafes, shopping centers and other similar places.

Positive sides:

- Resistant to moisture;

- Long service life, resistance to deformation, quartz crumb is a part;

- Environmentally safe product, fireproof, has a sound insulating property;

- The construction is monolithic and non-slip.

Negative: high price and a small palette of colors.

It is divided into two types: heterogeneous (multilayer) and homogeneous (single layer), they are the same in terms of service life, cost, but different in scope. Multi-layer are more suitable for premises with the requirement of thermal and sound insulation. Single-layer is applicable in places where there is a high probability of mechanical damage.

Laying such coverage should be done only by a specialist. In case of need of its pasting the method of hot welding is applied.

When do you need bonding?

Linoleum of domestic production is most often produced in a width of 1.5 meters. It is great for compact rooms, but there is a problem with large rooms. Indeed, in this case, laying in separate strips and further welding of the seams is envisaged. In some cases, the coating has to be joined as a mosaic and glued in parts.

Many professionals advise to lay linoleum as completely as possible.

Before buying the material, the area of the apartment is measured and the required footage of the roll is calculated from this figure. Dock seams begin after flooring. It is possible to fix carpet or to mark the transition between rooms.

Splicing methods

Previously, the edges of linoleum could only be soldered together with a special soldering iron. The seams were uneven, stood out strongly and spoiled the entire appearance of the floor. Holding a similar mount for long. Now new, practical and reliable methods of soldering have been developed.

There are several ways to connect the joints - it is hot and cold welding. Cold helps to glue the flooring by applying a special adhesive,and hot - soldering special equipment. Also use additional methods, such as double-sided tape.

For laying linoleum on top of other materials or if the edge is lifted, rubber, wooden or metal powders are used (mechanical method).

It is possible to join the seams with your own hands at home only by cold welding, tape or the nut. It cannot be argued that one method is good and the other is bad. It all depends on the specific case, the specialization of the room and the type of linoleum.

Hot welding

It is necessary to immediately note the inappropriateness of the method at home. Household linoleum is not resistant to high temperatures and eventually just melts. The technology is mostly designed for a very durable and wear-resistant material, which is mainly used in commercial or industrial enterprises or to create complex application work.

For work you will need:

- connector - polymeric cords (welding);

- soldering device - heat gun and nozzle;

- PTFE tape;

- sharp knife.

It is better to rent a hairdryer, as it is a tool of narrow specialization and most likely will not be needed in the future.

Soldering Technique:

- Linoleum is firmly attached to the floor with PVA glue or PTFE tape and the edges are adjusted. Dust, water and debris are pre-removed;

- Over the entire length of the joint, cut a recess in the form of a V-shaped groove with a sharp knife or chisel;

- Attach the nozzle to the machine for soldering. The cord is inserted into the nozzle;

- Only after that the hair dryer is turned on and heated to a high temperature (300-600 ° C). Good equipment should have sensors and temperature control;

- Edges degrease for better grip. They carry out a hairdryer through the junction, not lingering in one place. It is necessary to solder smoothly over the entire length. The polymer should protrude somewhat beyond the seam. The cooled seam is cut off along the entire length by an arcuate knife (the seam should be warm, but already seized). Soldering is more convenient from the wall to the middle of the room, and also from the opposite side.

Advantages of the method:

- The seam has a long service life;

- Strong and reliable connection.

Minuses:

- Road equipment and supplies;

- Soldering requires equipment skills;

- The seam is quite noticeable;

- Not suitable for domestic linoleum.

You can also weld linoleum with a soldering iron or iron.Although this method is outdated, but sometimes it still occurs. The soldering iron is convenient in small rooms with inconspicuous, few joints.

The essence of the technique is simple: the soldering iron heats and melts the edges of the sheets, they are connected to each other. The resulting seam is cut when necessary. So that it does not stand out strongly against the general background, in a fresh and soft seam, pressing it with a roller is carried out several times.

Plus - simplicity and accessibility.

Minuses:

- Joints do not look aesthetically pleasing;

- They are brittle and do not last long;

- Modern types of coatings do not melt well under the influence of a soldering iron.

Details on how to glue the linoleum using hot welding can be found in the video below.

Cold welding

This is a modern technology that is ideal for those who have no experience in similar work, but want to process joints independently and at high quality at home. Adhesion of the edges by cold welding is carried out with the help of specialized glue.

Such processing has a number of positive moments:

- There is no need to hire professional workers and purchase special equipment;

- Enough economical option that does not require large cash costs;

- The seams are neat and almost invisible.

Set for gluing:

- wide paper tape;

- knife (not office!);

- ruler;

- glue (cold welding).

Household welding is divided into three types - "A", "C" and "T":

- Type "A" is well suited for gluing new, only lined linoleum. The consistency of the glue is sufficiently liquid, it makes it even safer to hide the seams and ensure a tight fit. It literally melts the edges and sticks them tightly;

- Type "C" is focused on the old coating. Here the glue is much thicker, the texture is similar to jelly. This determines its ability to fill large gaps. With it, repairing the old coating, cracks, such seams do not get dirty. The finished seams are obtained with a width of about 4 mm;

- Type "T" is designed for polyester materials. Working with this composition requires knowledge and skills. It is very toxic.

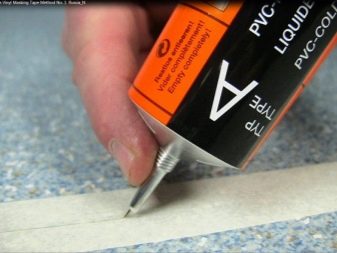

Glue is available in tubes and sold in hardware stores. At the end of the bottle is a needle-tip, which should be thin enough for deep penetration into the seam.

Before gluing the linoleum, you should spread it out and leave it for about a week.During this time, he smoothed out and adapts to the shape of the floor. After cutting off the excess parts and fix on the baseboard. The floor is pre-washed and primed if necessary. To make the seam even less noticeable, sheets overlap one another. The coating without a pattern will need about 4 centimeters, and the presence of the pattern will require adjustment.

Technique cold welding with overlap:

- The upper part bends, the adhesive tape is glued in the middle and on the lower part. The same strip is attached to the top;

- A ruler is placed in the middle and along the line is cut with a knife down to the floor;

- The cut parts are removed, so a tight connection is obtained, protected with duct tape;

- Now in the middle of the incision site is filled with welding (the spout sinks to half), the glue protrudes a little;

- After 15 minutes, the composition dries, after you can remove the tape.

Cold welding technique without overlap:

- As much as possible pruned edges. If there is a drawing, then it is also customized;

- Paste a wide paper tape. It is needed to protect the material and highlight the area of bonding. In the course of the seam adhesive tape is notched;

- Focusing on the tape, glue is applied to the seam.It is important to prevent it from reaching the unprotected surface. It is impossible to clear the coating from it;

- After 15 minutes, the tape is smoothly removed. After 2 hours, you can safely walk on the floor.

- The technique is designed for new coverage. When gluing the old, all the points are observed, but the adhesive tape can be not glued, since the linoleum is already “lying down” and does not need additional fixing.

Repair of torn linoleum:

- Cracks or defects are thoroughly cleaned and degreased, glue tape;

- We cut through the gap, opening access only to the damaged area;

- Fill it with glue (type “C”) and wait for it to dry completely;

- Remove the tape and excess glue.

If the damage occurred on a fresh canvas, for example, when rearranging furniture, then we take type “A” glue.

Pros:

- Ease of use;

- Suitable for home use;

Some tips from professionals:

- The spout of the tube of glue should go deep inside the seam;

- The layer is applied along the entire length, speaking no more than 4 mm above it;

- Rag convenient to quickly remove droplets from the surface;

- Remove excess should be after complete drying, so that the glue does not move away from the edges;

- A tube of glue is better to hold with both hands;

- Glue is an aggressive chemical, therefore it is necessary to observe safety measures and work only with rubber gloves and a respirator;

- During operation, ventilation is required, after airing the room.

The disadvantage of this method is the inability to use it on the flooring with insulation or a soft base. The joints are uneven and inaccurate, and the seam is visible to the naked eye and spoils the appearance of the floor.

Double-sided tape

The easiest, but unreliable way. That's because no one, even the best scotch tape, is designed for a long-term load, and its adhesive ability weakens over time. In order to glue it, fit only a flat floor without bumps. Based on this, it is better to prime the entire surface with a special reinforcing primer before working.

In this way, you will stick linoleum only on a fabric basis.

Sizing:

- Put in order the area under the proposed joint, primed, remove garbage;

- It is important that the edges are straight and tight to each other without gaps, we customize the drawing;

- Scotch sticking to the floor.With one hand, carefully remove the protective tape, and the second tightly press the edges of the sheet;

- Upon completion of the work, it will not be superfluous to roll a joint with a roller for a better grip.

Pros:

- Ease in execution;

- Efficiency.

Minuses:

- Joints weak;

- The place of the joint is noticeable.

The method is considered rather temporary, in the future it is necessary to glue the linoleum in other, more reliable ways.

Porozhek

The method is used when moving from one room to another (for example, between a corridor and a kitchen), fixing materials over linoleum allows you to close two pieces and seal the seams. Metal thresholds connect two materials of different structure. The range of thresholds is not too extensive, but you can find a suitable color option. This is a simple docking, which does not require special knowledge and skills, and therefore it is the most common.

Performance:

- Purchased threshold should already have ready-made holes for screws. Measure the desired size (the bar is applied to the floor and mark the places of the holes) and cut off;

- An electric drill with a 6 mm drill makes holes through the marks made. Plastic dowels are inserted into them;

- Now we apply the finished bar and fasten with screws in the marked places.

Pros:

- Reliable seal joints and transitions;

- Reasonable price. Thresholds are sold by the meter for 2-3 meters, so 12 pieces will be enough.

Minuses:

- It will protrude over the floor and cannot be hidden by anything. Perhaps this fact will not please someone very much;

- Sometimes it is difficult to pick and match the color, especially if there is a complex pattern on the linoleum.

Details about this method, see the video below.

Of course, the most successful examples of welding are cold or hot.

They securely fasten the two canvases and hold them in such a state for a long time. The choice of method depends on the type of linoleum itself, the purpose and configuration of the seam. However it is better to refuse hot welding in living conditions. It is more expedient to use cold, not requiring special skills and knowledge, as well as special expensive equipment.

Ideal installation means no joints, but even if they were not avoided, you can make the seams almost invisible and resistant to mechanical and chemical effects.