All the details of the choice of floorboard

To date, a huge amount of flooring is presented in the building stores - this is laminate flooring, linoleum, and parquet flooring, carpet, and tile or ceramic tile. But a special place in a residential house on the floor for centuries has been occupied by the board.

What it is?

A floorboard is a device made of solid wood, unlike laminate or floorboard. In this regard, its surface can be scraped several times and the product will not lose its commercial qualities.

Fixing of floorboards is carried out thanks to a groove and a crest.

To relieve tension between the rows and to avoid distortion caused by changes in humidity and temperature in the room, a recess is located on the inside of the board. Some models are equipped with a protrusion of a quarter.

For the manufacture of massive boards using hard and soft woods.Not suitable for flooring only products from poplar and linden.

Soft woods from coniferous families require a mandatory protective coating. For these purposes, suitable varnish or paint.

Special features

Before buying a floorboard, it is important to know its pros and cons. The advantages of this building material include the fact that it has good wear resistance and strength, perfectly retains heat in the room, is made from environmentally friendly materials. Besides, solid board does not emit substances harmful to humans, unlike glued flooring, has good antistatic properties.

Among the shortcomings can be noted the poor sound insulation, demanding for constant care. Under no circumstances should building materials be overwetted.otherwise the floor will swell and the board will start to rot. There may be scratches on the surface that need to be masked.

Heavy household appliances and large furniture in order to prevent dents are recommended to equip rubber inserts.

Another significant disadvantage is the annual update of the protective coating. Periodically, the floor must either be varnished or painted.. The tree itself is combustible, it is exposed to the colonization of fungi and insects, which means that the fire, antifungal and sanitary treatment will be in the room.

The floorboard can be destroyed by mice or rats - it is especially important to take this into account in the private sector. The tree deteriorates due to changes in temperature and humidity, the plank floor may fade, swell or crack. Some types of flooring are expensive.

Kinds

Floorboard can be engineering, ship, edged, terraced and spliced. Below will be considered each species separately, its pros and cons.

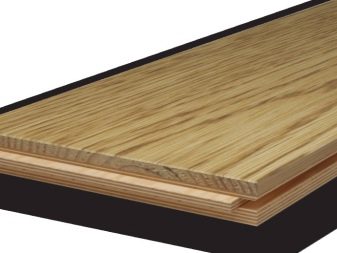

Engineering board is found only in Russian hardware stores, the usual name for it is a two-layer flooring board. Judging by the name, it is not difficult to guess what a floor covering consists of two layers. For the front layer are often used solid wood - it can be oak, larch, ash. Moreover, the thickness of the upper layer usually does not exceed 25-30% of the total; glued plywood sheets are used as the base. The number of sheets can vary from 7 to 9 pieces, almost all manufacturing plants use birch to create its base.

Despite the fact that the sheets of plywood are mounted perpendicular to each other, this does not save her from warping, therefore this type of flooring is not suitable for floating floors. In addition, the engineering board is laid using adhesive composition.

The advantage of this building material is that It is suitable for most rooms, styles and designs. The board is less susceptible to deformation due to the large number of perpendicular glued plywood sheets. It can be scraped without fear of damaging the coating, but after that it is desirable to treat the product with varnish.

Some manufacturers produce thin products that are perfectly combined with a floor heating system. Such a floor does not crack due to high temperatures, and its service life is not reduced. In addition, thanks to moisture-resistant plywood, the engineering board is also suitable for rooms with high levels of humidity - bathrooms, kitchens, and swimming pools.

The main feature of this flooring is considered to be the thickness, as it may differ. Even in rooms with large differences you can lay a flat floor,for this you only need to choose building materials of the desired thickness.

Unlike other varieties, when laying engineering board does not require plywood substrate. Installation can be done with herringbone, tile, diagonally. Many manufacturers for a fee perform tinted product.

Since fixing is carried out with the use of glue, there are no cold bridges between the planks, through which extraneous noises can flow. No special temperature conditions for the room are needed, there is no need to maintain constant humidity.

The main disadvantages are considered to be the high cost of the product, and the floor cannot be disassembled and placed elsewhere, such as, for example, laminate. If any lamella is damaged, in order to replace it, you will have to tinker, and besides, choosing the color most likely will not work, because not only the color will differ, but also the wood pattern.

Installation of an engineering board is quite complicated, not all specialists take up the laying of such a floor covering.

Keep in mind that in the markets a large number of fakes, there is a high probability of buying a cheap low-quality counterpart at the price of an engineering board.

For additional sound insulation, experts recommend buying an acoustic substrate, in which there are special slots where the glue is poured. This significantly saves time spent on installation, since the glue is not applied to the entire surface and, consequently, money.

Like laminate flooring, After the purchase, this building material should be held in the room where the repair is to be. In a few days the tree will get used to the temperature conditions and the humidity of the room.

Shipboard, or deck board is used not only for laying the floor on ships, but also in rooms with high humidity. This is due to the fact that the deck board has good wear resistance and moisture resistance. In addition to kitchens and bathrooms, it is bought for floor installation on loggias, saunas, gazebos and swimming pools. It is suitable for the veranda, and for the terrace.

Often it is made from solid wood, namely larch. A well-known fact, larch can last up to 30 years, of course, with proper care. Other types of wood are also used - this is both the South American tiger and Indian teak.

Another advantages of this flooring include ease of maintenance and resistance to the environment. The material does not deteriorate due to high humidity, low temperatures, does not fade under the action of ultraviolet. The disadvantages include the non-democratic value of exotic woods.

Installation is carried out either on logs or on a cleaned concrete base. Fastening can be carried out in the open and hidden way. The first is done with a screwdriver and special screws. Moreover, the holes are drilled in advance to prevent damage to the product. The second method involves the use of special fasteners and lamellar cuts, with it using a shallow propyl.

Keep in mind that there should be a gap of 10-12 mm between the boards.

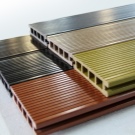

The terrace, or composite board, unlike deck, is made not only from a tree, but also from a wood and polymeric composite. Most often it is a combination of fiberglass, sawdust, chips or flour with plastic - in other words, from waste products. Due to this, the lamellae can be both small and large sizes. In this regard, this type of flooring can be quickly mounted.

Wide and thin plastic is more susceptible to deformation than narrow and thick.Although some manufacturers guarantee that their product is capable of withstanding a mechanical load of 350-400 kg per square meter.

Drevoplast does not fade in direct sunlight, does not change its color and does not crack. And from this it follows that such flooring will last for several decades.

The advantages of such a board can be attributed to the fact that its edges are rounded, thanks to which the probability of injury is reduced. Neither moisture nor frost is not terrible for quality plastic, so styling can be done not only in residential premises, but also in the open air. But at the same time it is important not to forget about a small bias - this will ensure the removal of moisture.

The plastic surface does not have a sliding effect, which means that it will not slip either after the rain or in the frost. Even small children can run on this flooring.

Easy and care of plastic, just wash off the dirt with a wet cloth or use cleaning products. By the way, a good plastic product does not deteriorate when interacting with household chemicals. But stiff brush cleaning procedure is strictly prohibited.

Laying decking is done on logs. The step between the lags will depend on the load on the floor - the bigger it is, the smaller the distance between the bars should be. Fastening, as well as the deck board, is carried out either in an open or hidden way. Remember to leave a short distance between the lamellae for thermal expansion.

Under the terrace board you can mount a warm floor. At the same time, it is necessary to look at the labeling of the product - usually the manufacturers print special signs or inscriptions on the packaging, indicating the combination of the board with the heating system.

Additional processing or painting boards do not require, since the mold, insects and microorganisms do not inhabit this flooring. In this regard, you can significantly save on annual prevention and protection.

The edged board, in contrast to the non-trimmed and half-edged variety, has all sides cut off, both front and end. Thanks to this, the flooring is perfectly even.

In the building stores there are several varieties of edged boards. Top grade is almost impossible to find on the market, as this reference product is exported to other countries.Yes, and it is produced according to European or American standards, which are foreign to the domestic consumer.

As a floor covering is used either the board of the first grade, or the second. In order to save, experts recommend buying a second grade. Small differences exist in quality and durability, but in general for residential premises this is considered to be an ideal option.

Board is selected and depending on the load. These can be either softwood or hardwood. As already noted, larch will last longer, but it costs more.

It is important to know that GOST clearly regulates the quality of edged boards. So, for example, in products of the first and second grade there should not be any cracks, chips, knots. The tree must necessarily be dry, otherwise the building material will quickly become unusable.

Since these boards do not have a locking connection, the fastening is carried out with the help of hardware. It can be nails, then a hammer is used to hammer them in, or self-tapping screws or anchor bolts, then the installation is done with a screwdriver.

Many manufacturing plants have learned how to recycle waste.Due to this, such a floor covering as a spliced board appeared. It is a strong building material, made by splicing coniferous wood. These slats are perfect for living quarters, and for country lanes or for terraces.

Usually either pine or oak or ash is used in production. On the surface of such building materials there are no cracks or chips. as well as knots or resin pockets, which are often found at edged boards. The base is even, uniformity is preserved both in color, and in structural content.

At the production stage, a lock connection is created. Fastening at such board is carried out on width. Product length can be 40-80 cm.

There are four classes of spliced board. Class D1 is suitable for ordinary rooms, class D2 is often used for flooring in kitchens, D3 for bathrooms, and D4 for rooms with high humidity.

The spliced board is sold at a reasonable price, suitable for universal use, it is easily painted and treated with varnishes or impregnations. It can be looped up to 5-7 times.It has a high thermal conductivity.

The main feature of this type of flooring is the possibility of individual cutting dice to the desired size. Any manufacturer will produce a board with the necessary dimensions for a fee.

Material

As already noted, in order to make a wooden floor, you will need a floorboard. Most often it is produced from wood cuts. So, for example, edged board is made of soft or hard wood.

Softwoods include pine, spruce and other needles. Linden and alder possess average hardness. Well, the standard for interior and exterior decoration is larch, because it does not deteriorate at low temperatures and at high temperatures. By the way, and lining is often made from these varieties of wood.

Pine wood is suitable for rooms with low humidity and constant temperature, the indicator of which should not exceed +30 degrees Celsius. Linden plank is suitable for wet rooms - bathrooms, bathrooms and baths, as it withstands temperatures above 100 degrees.

After the “iron curtain” was removed, products from exotic tree species began to enter the domestic market. Many of them are distinguished by a high price tag and not all people can afford, but there are also available copies. One of them is bamboo flooring.

Bamboo is a building material that is resistant to physical stress and has a long service life. He, like all wooden floorboards, is an environmentally friendly material. Due to the fact that its wood matures in a short period of time - 4-5 years, there is no shortage of this product, this significantly affects competition and allows reducing the price of products.

In addition, the bamboo board is suitable for many interiors, it is easy to care for. Some manufacturing plants impregnate their products with special compounds, because of this, the board becomes waterproof. She can cover the floors in bathrooms and kitchens.

But keep in mind that some manufacturers use cheap resin for impregnation. A floor made of such boards may be detrimental to the health of not only small children or allergies, but also adults.

Scratches may remain on the surface of the bamboo, so sanding the base will be necessary to give the floor a former beauty. In this regard, experts do not recommend bamboo board as a floor covering for corridors and hallways.

Despite the fact that this building material can be mounted in rooms with high humidity, it is necessary to periodically monitor the protective layer. In the case of abrasion will require a new layer. Keep in mind that painted boards have less wear resistance.

Bamboo can be laid on a concrete, reinforced concrete or wooden base. In the first and second variants, the surface must be leveled using a reinforcing mesh. And for the third option you need to fix the logs.

Some plants in order to make the boards less rotten, they are burned at the production stage. Acetic acid and binder resins are formed in the burnt slats, which makes the product more resistant to environmental changes.

This technology first appeared in Japan. There, houses were built from the burned board that were not only not rotten and were not inhabited by pests, but were also considered to be fire resistant.At the same time, their service life increased to 80-90 years. In Russia, this technology was called "smoking." In addition, this technology allows even cheap wood to modify.

Dark finishing material is perfect for old styles and for new directions. It is also important that under the action of sunlight the board does not change its color.

The terrace or wood and polymeric board (DLK) is made from PVC, wood flour and from water. A color pigment is added to create a particular shade. The combination is carried out in a certain proportion, so that the product turns out to be moisture-resistant, resistant to temperature changes, rotting.

As a basis for DLK can be a substrate of wooden slats or plastic grille. In the first case, the floor is hard, and in the second - soft and less resistant to stress.

Dimensions

When buying flooring need to start from its purpose. The board can be used for finishing and for rough finishing. Often the thickness of the board varies from 20 mm to 70 mm. Experts advise to choose a board of such length at which the waste will be the minimum amount.Keep in mind that the smaller the joints on the surface, the more beautiful the flooring looks. Some products are available in lengths up to 6 meters.

The floor should be periodically cycled, which means that the width and thickness of the board should be appropriate for this operation. Thin planks can hardly be polished. On sale you can find a board, whose width is equal to 80-135 mm.

For city apartments and for country cottages, a slat with a thickness of 35-50 mm is considered an ideal board, for commercial use - 50-70 mm. The width should be 100 mm.

The dimensions of wood-polymer boards are slightly different. So, its width is 160 mm, length - 2-6 m, and an average thickness of 25 mm. Due to the fact that the product is made of plastic, the weight of the final product is several times less compared to a wooden board.

When choosing, do not forget about transportation. Long boards can be transported only by special transport. The thickness and width of the product affects the crate. The thinner the building material, the narrower the distance between the lags should be. Otherwise, the floor may be deformed.

Colors

A huge selection of colors different composite board.Since at the production stage you can add any color pigment, respectively, the final product can be a familiar or exotic color. In this case, the shade can be adjusted by tinting. Due to the fact that the paint is applied inside the product, it does not fade and does not fade during operation.

Coloring can be monophonic or with a pattern imitating wood structure. Modern technology allows to imitate not only the tree design, but also the roughness. When touching the surface it is very difficult to distinguish, natural is a product or its high-quality analogue.

As for the natural wood, each species has its own color. So, for example, ash has a light yellowish tint, and alder - white. And the oak at all during the operation may darken.

Plants manufacturers bleach, burn and tint their products. Each of these processes can emphasize the texture and structure of the wood, endow it with a specific color - white or black, respectively.

Type of flooring

Already casually noted that if the floor is heated, then it needs a special floor covering that withstands high temperatures.Many boards will quickly become worthless, lose their appearance and may even become a source of trauma for households.

Remember that if the apartment has an old wooden floor, some of its elements that have failed can be replaced. This saves both time and money. Installation is carried out on beams using self-tapping screws and a screwdriver.

For a subfloor, it is recommended to buy a board made of soft wood, because the strength is important for the base, not scratch resistance. Lamellae should not be damp or wet, populated with fungi or pests, uneven and cracked. And also the draft floor should not have gaps. Boards without fail are treated with anti-fungal compounds. Particular attention is paid to the ground, if the repair is done in a private house. If installed on a concrete base, it should be degreased and treated with a primer.

Style and design

Each wood has its own texture pattern. It depends not only on the name or type of tree, but also on its age. The more years the tree, the more circles can be seen when cutting.But, unfortunately, this feature can play a cruel joke. For example, in the case of replacing one board, it will be problematic to pick up a pattern or background.

Some manufacturers make special changes to their products - they add scuffs, chamfers, cracks or wormholes so that the board is suitable for the classic style.

As noted earlier, the edged board is fired, after which it becomes black. This flooring is perfectly combined with elegant black furniture, gold-plated, mirrors and chrome inserts. Suitable for rooms designed in the style of hi-tech and loft.

Which is better to choose?

Being in the hardware store or on the construction market, you must pay attention to the humidity of the board. This figure should not exceed 20 percent. Raw wood weighs more. Well dried batten will last longer.

The board must comply with the required class, free from defects, including the lock connection. In the store, it is advisable to insert one board into another and carefully look at the connection. Certain difficulties may arise with the connection of six-meter boards, here you will need to use the help of a sales assistant.

It is important that terraced, engineering and ship boards do not have scratches on the surface. If the protective layer is damaged, then molds, microorganisms and pests will begin to populate through the cracks.

Composite lamellas made of high-quality plastic will last for several decades. No need to buy wide planks. As a rule, they are less resistant to loads, which means they deform faster.

Important nuances

Remember, the step between the lags will depend on the load on the flooring. If the load is large, then the lags are stacked through a small distance. This technology will relieve the load on the boards, which means that the lamella will not break with the weight of heavy furniture or a person.

Wood has the peculiarity of expanding and tapering due to a drop in humidity and temperature. Therefore, a small gap is left between the boards - this is a kind of ventilation. When the plank grows, it will not harm the “neighbor” and the floor will remain unchanged. If this is not done, then the floor “will rise a house.”

Do not forget about the waterproofing layer, it will not allow moisture and a couple of negative effects on the properties of the plank floor.In addition, between the lags, you can put a heater and a sound insulator, thanks to this, the room will not receive cold air and noises.

It is important to protect the floor to use not only anti-fungal drugs, but also paint and varnish coatings. With their help, you can avoid damage to building materials, to extend its service life. Painted floor will fit into any interior.

Reviews

Analyzing feedback from buyers of the floorboard, we can note the following: those who fastened the lamella with self-tapping screws and the lock joint, complain that the boards are bent, after which such a floor cannot be disassembled, which means that a complete disassembly of the flooring is to be done.

You should know that you do not need to touch the thermowood, because it during the operation neither expands nor narrows. If the mount was carried out in an open way, then the replacement board takes place in a few minutes.

Some buyers got a non-standard and re-grading, respectively, low-quality building material was bought for a lot of money. Therefore, when choosing a trim board, you should not hesitate to require certificates of conformity from the seller.

After laying the floorboard, it is necessary to grind, otshkurit and ottsiklevit surface, and only after that cover the base with varnish or paint. This operation is to be carried out annually, so it is important to weigh the pros and cons before buying building material.

Care Tips

First of all, before installation it is necessary to process the building material with antiseptic, antifungal agents. Every year, the surface must either be painted or covered with a layer of varnish.

Only dry cleaning of a floor made of wood is permissible. To do this, use either a vacuum cleaner, a broom, or a soft brush. Wet cleaning is done with a mop, but keep in mind that it should be wrung out well, otherwise the water, hitting the surface, will leave traces that after drying will appear dark spots. With abundant wetting, you can completely ruin the product.

In the hardware stores sold a special tool for cleaning wooden floors. It can be added according to the instructions in a bucket of water. Metal brushes, abrasive substances will have to be abandoned, they can spoil the protective layer.

If the plank floor is laid in the hallway, to protect it from dirty shoes, it is advisable to lay a rug in front of the entrance door.

At the same time do not forget to periodically sweep the sand and dust formed under the mat. These solids can scratch the board.

Pets can ruin claws. To avoid this, periodically cut their claws. If all the same scratches appeared, then you should buy tinting pencils in the building shop.

Beautiful examples and options

In this section, different floor coverings are presented in the interior of the apartment and in the private house. Moreover, their installation was carried out not only by experts, but also with their own hands - in the living room, hallway, in the kitchen.

How to choose the right boards, you will learn from the video below.