Laying ceramic tiles under the laminate: the pros and cons

Using ceramic tiles instead of laminate has proven to be a very practical option. To meet in the bathroom, bathroom or even in the kitchen a wooden covering does not happen often, but the tile is another matter, the material protected from moisture is great for wet rooms. But the wooden structure, in spite of this obvious minus, still has a very beautiful look, which many people use when decorating their rooms.

That is why they use tiles decorated in the form of laminate, combining the beauty of wood and the practicality of stone.

Special features

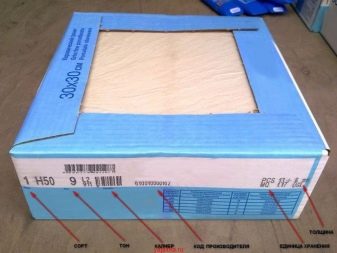

The main features of the use of ceramics are the undoubted advantages of this material. Using ceramics or porcelain tiles, made under the laminate, you get all the advantages of both conventional floor tiles and simple laminate, which is placed in bedrooms and other living rooms - this is practical, beauty and protection from moisture.The size and proportions of the material are often similar to the natural board, to simulate the floor using a plate in the shape of a square.

Ceramics, like laminate, can be with or without a beveled edge. Plates in a set without bevels, are used for laying without seams, after firing, they are calibrated in a special way on factory grinding machines, therefore, This material has a higher price. For a complete set of registration of the floor under the laminate in the collection there are curbs and baseboards.

Lay ceramoparket on a similar principle with conventional floorboard or laminate: Herringbone, razbezhku, basket and so on. Because of this, the work starts with the initial counting of the required plates for this room. This should take into account the method of laying, the need for undercuts and options for the secondary use of cut pieces.

How to make a layout and calculate the number of tiles, see the following video.

Kinds

The variety of tiles that can be used for masking as laminate or wood is sufficient:

- Ceramic or tiled is a mixture of clay, sand and various minerals, kilned in a furnace at high temperature and coated with glaze, which makes it possible to give the tile any color and texture.

- Porcelain stoneware - tile, having the properties of a large water absorption and frost resistance. It is made of materials close to those of which porcelain is made. Porcelain tile is made by the method of dry pressing and single firing.

- Clinker is a tile produced by the method of single firing and having a compacted structure. Such a tile is made by pressing through a mold or by pressing.

For this reason, you can make tiles of various shapes, for example, in the form of parquet.

Advantages and disadvantages

Using porcelain stoneware as a flooring alternative to laminate has several advantages:

- High resistance to temperature extremes. In the heat, the stone will not crack, unlike wood, and it will not be covered with cracks from the cold. Naturally, when planning the installation of a heated floor, it should be considered tile, to put a real laminate means only to throw money down the drain.

- Durability. Unlike conventional laminate, porcelain stoneware is very wear-resistant - if the laminate lasts for several years, ceramics can serve dozens.

- Environmental friendliness.Ceramics is a natural material, the production of which involves only natural components.

- Moisture protection. Ceramics will not swell due to water, and if it is good to seal up the interplate space, your neighbors will not have to worry about possible flooding.

- Long service life. The tile will be able to serve you up to half a century.

- Long-term preservation of appearance. If abrasion and discoloration will appear on the laminate over time, the tile will look like new for a very long time.

- Easy to care. To wash the floor, tiled, it is enough just to wash it with water.

According to this list, ceramics is an excellent material for the floor, which does not have the disadvantages of laminate, but also without cons, too, not done:

- The price for the material in comparison with the laminate is higher.

- Ceramic tiles are very cold, so installing a warm floor is desirable.

If you summarize all of the above, it seems that the tile is ideal for flooring, and in general, judging by the reviews, this is exactly the case.

How to lay?

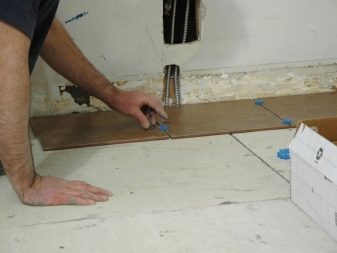

Lay on the floor tile under the laminate - not the most difficult task, so you can put it and your own hands.In general, this process is not very different from the laying of ordinary tiles, with the only difference being that the tile joints should be minimal to fit the laminate more closely. But even in the case of large intervals between the plates it is quite possible to use the ordinary grout for the tile. Grouting is sometimes used even when laying conventional laminate in the event of holes due to uneven floors or other reasons.

To lay the tile with your own hands, use the following instructions. Initially, you should do some preparations:

- First you need to prepare the necessary tools, namely, trowel, trowel, trowel with teeth, trowel of rubber, level, rubber mall, tanks for the solution, tile cutter and grinder.

- Secondly, it is important to calculate the amount of material: how much tiles will be needed, given that it is likely to be cut under walls, protrusions, pipes, or due to other obstacles. It should take a tile with a certain margin, but forget about the gaps, if you can not do without them, you can not.

We proceed directly to work, without forgetting that, ideally, for full compliance with the laminate, the seams between the plates should be minimal, and it is best to do without them. Prepare the surface. It should be perfectly flat and durable; you cannot count on leveling by using more mortar in irregularities. All this is necessary to ensure that the coating in the end turned out to be perfectly smooth.

To achieve a level platform, a screed is made before installation, and in rooms with high moisture content, a waterproofing layer is immediately drawn up. The most preferred option is laying tiles on a concrete screed.

We prepare the stops and markings for the first row. To do this, draw a line of the distant edge of the first row. Mark the position of different from other fragments in the case of a pattern or decorative inserts. We begin to lay the plates from the far corner. The first is the fragment without cropping. Tile laying options may be as follows:

- A seam in a seam or "checkers."

- Scramble or “braided.

- Diagonally or so-called deck.

- Herringbone.

- Labyrinth.

After marking the landmarks and preparing the surface, we begin to lay. Apply adhesive composition on the floor and on the plate itself.We make it a notched trowel. A few words in the adhesive composition. There is a wide variety of ceramics glue:

- Glue made of cement. The most popular glue consisting of cement, sand and polymers that increase the plasticity and water resistance of the composition. Sold in crumbly form, which when working should be diluted with water.

- Dispersion glue. This type is more expensive compared to cement, but the consumption of the mixture is almost halved. Such an adhesive has a stronger adhesion to the surface, as a result of which this adhesive is used for gluing plates on surfaces other than concrete or cement, for example, wood, plastic, metal, drywall, vertical and bending surfaces. In addition, it is not necessary to coat the base with a primer or sand it. Dispersion adhesive for ceramic tiles is sold ready to use.

- Epoxy adhesives. Multidimensional compound, which is added to the catalyst, enclosed in a package and packaged in different containers. But do not forget that he will not forgive mistakes and requires skill, accuracy and accuracy.In case of contact with glue on the finishing material, it must be immediately removed, or it will grab and become a very durable compound that is almost impossible to remove. Epoxy glue is excellent for use outdoors and in rooms with a lot of moisture. It ignores the effects of alkalis and solvents.

- Liquid Nails. In this composition there are polymers with synthetic rubber. Liquid nails on neoprene have high strength, but they are very toxic and have an unpleasant smell. Safe glue on a water basis will not cope with operation in rooms with big humidity due to the lack of moisture resistance. Therefore, ceramic tiles can be glued using liquid nails only when carrying out minor restoration work, for example, in the case of a few dropped tiles or for mounting small tiles.

We put the plate to the place of attachment, lightly press it and turn it a little along the axis to mix the solution as much as possible. Do not forget that removing the tile after it is laid on the mortar is not an easy task, it may only be slightly shifted to the side,therefore, work should be done as carefully as possible and in every possible way to check everything by level.

In case of irregularities Need to use a rubber mallet. But it is also impossible to press hard: the solution will protrude around the edges, and the gaps, which ideally should not be, should be as clean as possible. When the first row is completed, you need to wait for its glue to set. Before a break in work it is necessary to remove all the solution protruding from the edges.

After the arm is “full” it is possible to apply the solution, taking into account not one, but several plates at a time.

When all the whole tiles are laid, you need to start cutting the missing pieces, for which it is preferable to use a tile cutter or at least a Bulgarian. Marking on the tile is carried out taking into account all the gaps. To perform an uneven cut, use a manual tile cutter-nippers or an electric machine with a diamond wheel.

Although the installation of tiles under the laminate and assumes the absence of gaps, but sometimes you can not do without them, so apply a special grout. After hardening the solution with a rubber spatula, press the trowel into the joints between the plates.To do this, put a spatula across the seam, and they spend along with the pressure. It’s not worth it to be zealous.

To learn how to properly rub the seams, see the following video.

Modern models in the interior

Kerama Marazzi is a Russian factory for the production of ceramic floor tiles and ceramic granite. The factory offers a wide range of options for decorating a laminate flooring.

Modern technology to create plates with a pattern and texture under the tree can make ceramic tiles, almost indistinguishable from the outside of the usual laminate.

A large variety of choice goes beyond the usual colors and textures, and if lovers of conventional design can choose colors for natural wood, the “extreme lovers” of design will be delighted with unusual and exotic reliefs.

When the tile is laid in the shape of a Christmas tree, it is almost indistinguishable from the laminate.

And here in the form of braids, and here in appearance it is also quite difficult to distinguish.